Device and method for automatic winding and shaping of infusion set

A strapping device and infusion set technology, which is applied to the parts and packaging of strapping machines, can solve problems such as high labor intensity, and achieve the effects of reducing labor costs, improving product quality, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

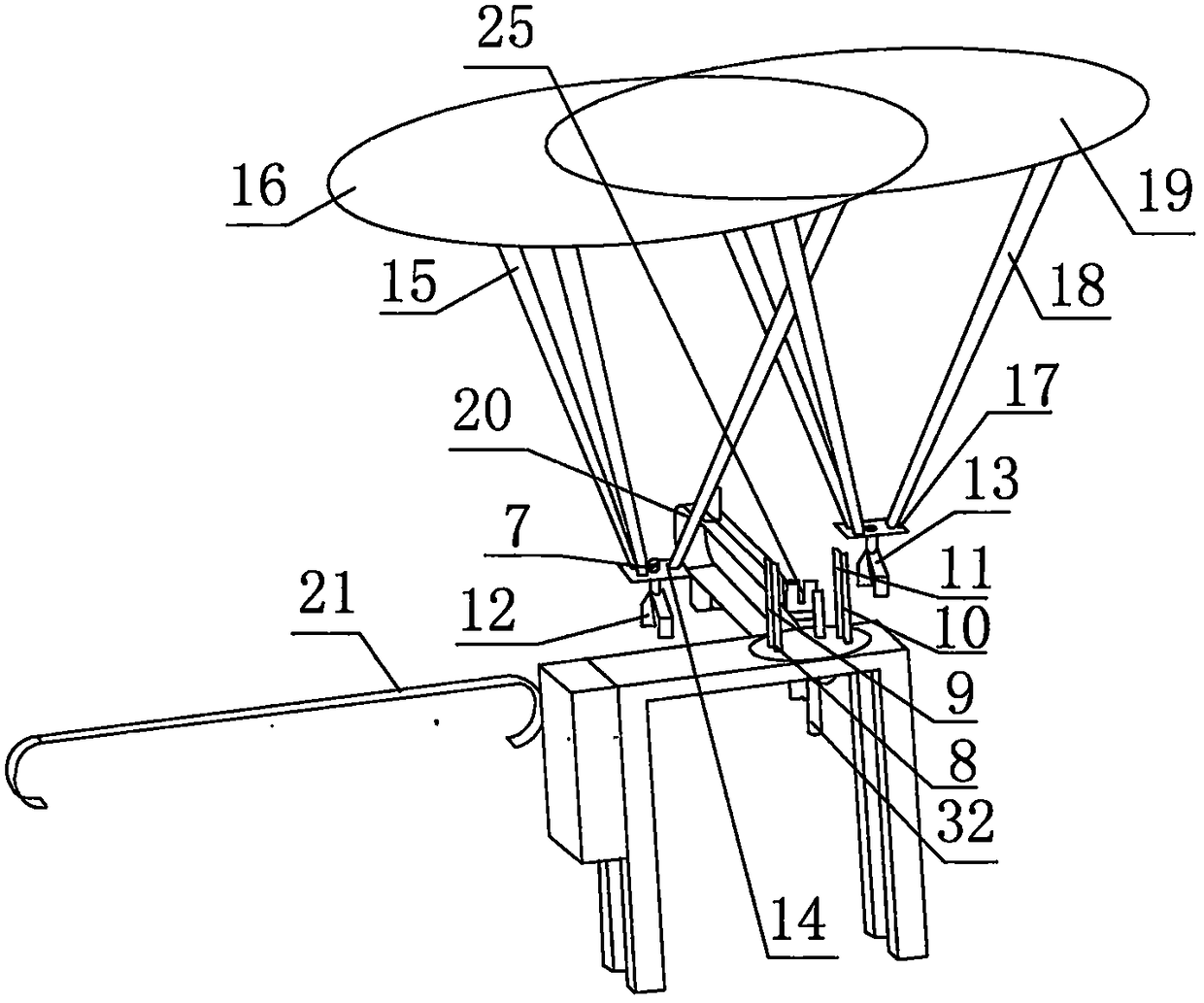

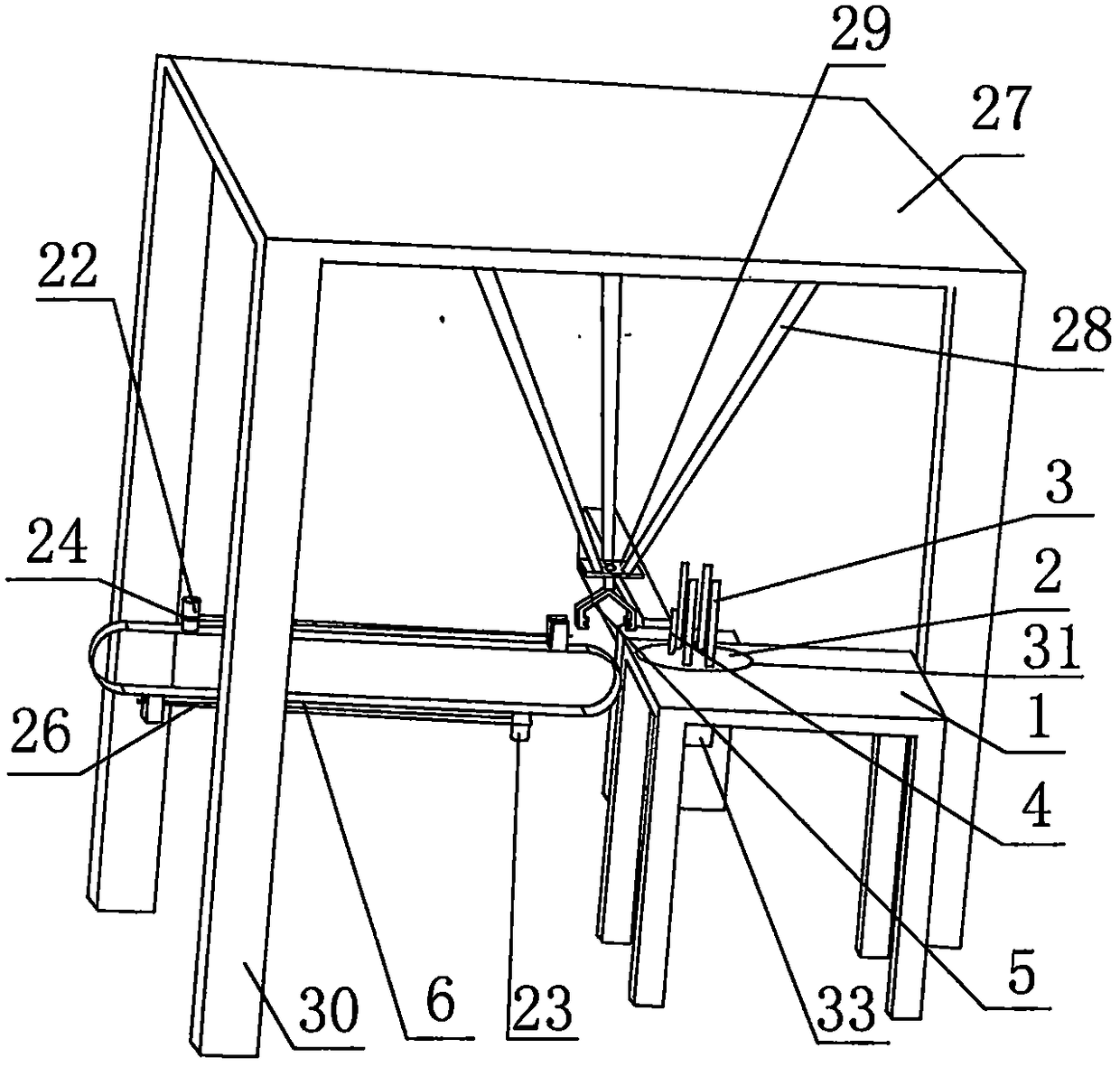

[0019] An automatic wrapping and shaping bundling device for an infusion set comprises: an infusion set 1, the infusion set is connected to a winding reel 2, the winding reel is connected to a winding post 3 and a winding reel clamp 4, the The reel is used with the manipulator 5 , the infusion set is connected to the conveyor belt 6 , and the manipulator is connected to the fixing device and the manipulator motor 7 .

Embodiment 2

[0021] The automatic winding and shaping bundling device of the infusion set described in Embodiment 1, the winding posts include a left front winding post 8, a left rear winding post 9, a right front winding post 10, and a right rear winding post 11. The manipulator includes a left manipulator 12 and a right manipulator 13, the left manipulator cooperates with the left front winding column and the left rear winding column, and the right manipulator cooperates with the right front winding column and the Right rear winding post.

Embodiment 3

[0023] In the automatic winding and shaping bundling device of the infusion set described in Embodiment 2, the left manipulator is connected to the left connecting plate 14 of the manipulator, the left connecting plate of the manipulator is connected to a group of left oblique pull rods 15, and the left oblique pull rod is connected to the left fixed plate 16 ; the right manipulator is connected to the manipulator right connecting plate 17 , the manipulator right connecting plate is connected to a group of right oblique pull rods 18 , and the right oblique pull rod is connected to the right fixing plate 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com