Large-sized vortex two-in-one impact crusher

An impact crusher, two-in-one technology, applied in grain processing and other directions, can solve the problems of material particle size and shape that cannot meet requirements, complex process, and small crushing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

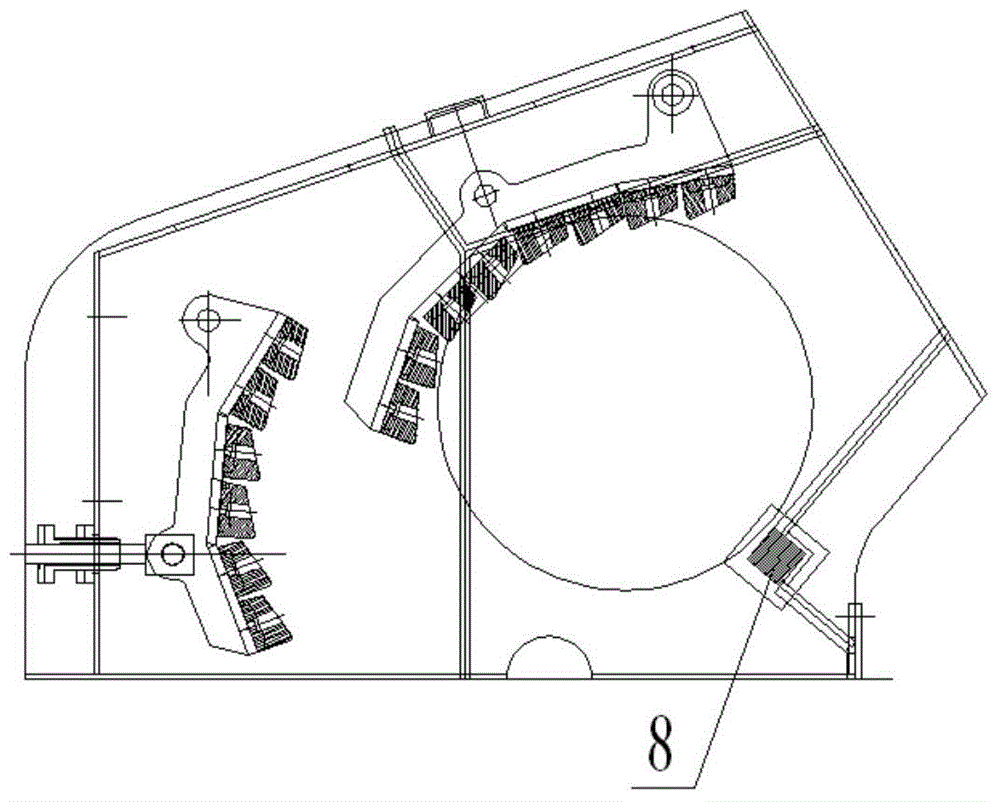

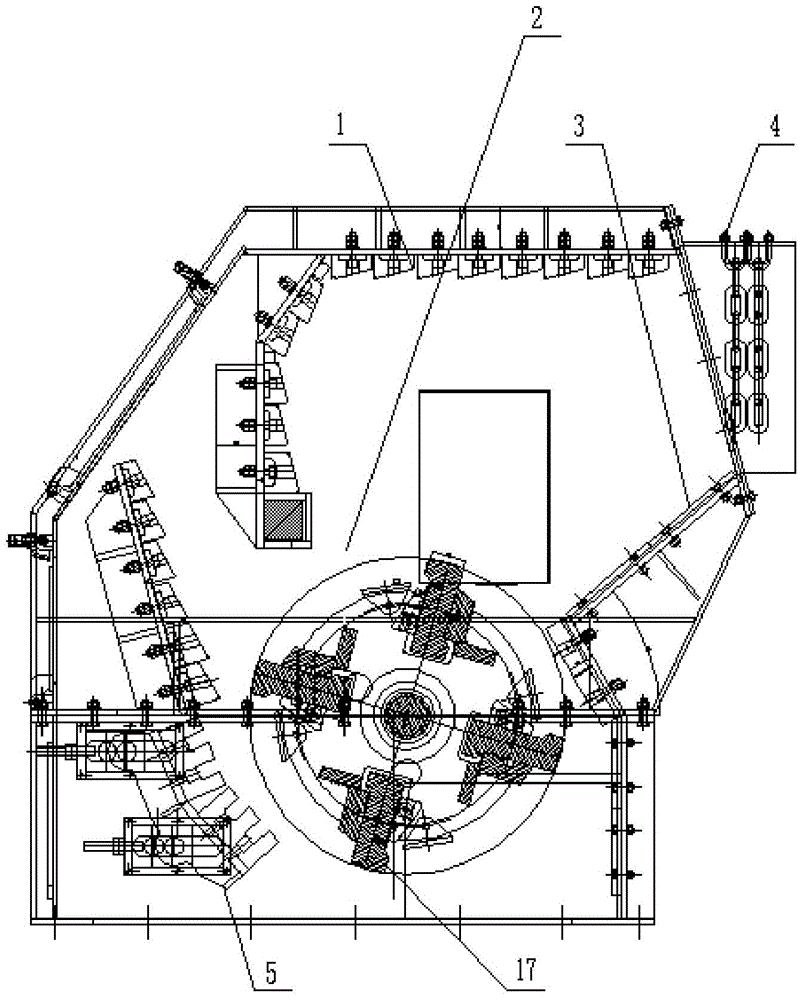

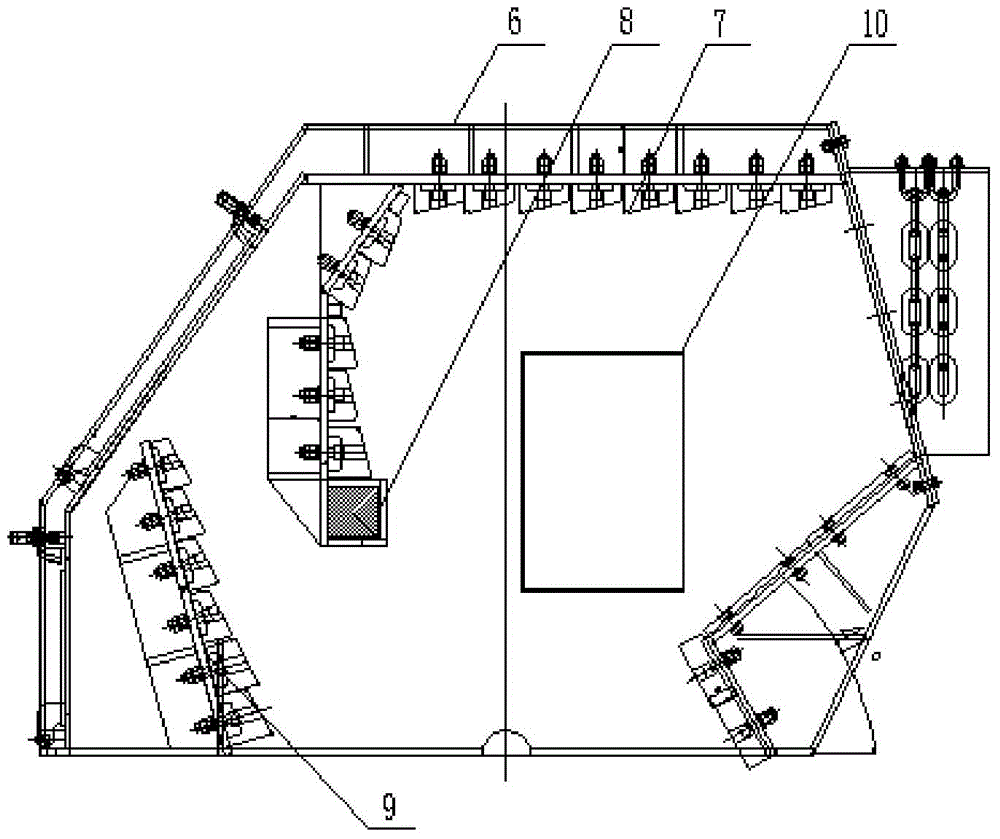

[0019] Such as figure 2 As shown, a large-scale vortex two-in-one impact crusher includes a vortex two-in-one impact crusher and a motor transmission mechanism, and the motor transmission mechanism is connected to the vortex two-in-one impact crusher through a V-belt. ; The vortex two-in-one impact crusher parallel adjustment impact plate assembly is installed in the lower body. The unique design of the vortex crushing chamber of the present invention, the discharge part of the vortex crushing chamber is equipped with powerful crushing and wear-resistant rods. Such as figure 2 The impact crusher shown in serial number 1 increases the space of the crushing cavity and is designed as a vortex type, while the crushing space of the traditional impact crusher is relatively narrow, which is not conducive to repeated impact crushing of materials; figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com