Multifunctional biological adsorbent and preparation method thereof

A biological adsorption and multi-functional technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of difficult recovery, slow separation rate, low recycling rate, etc., to improve the adsorption capacity, Stable physical and chemical properties and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

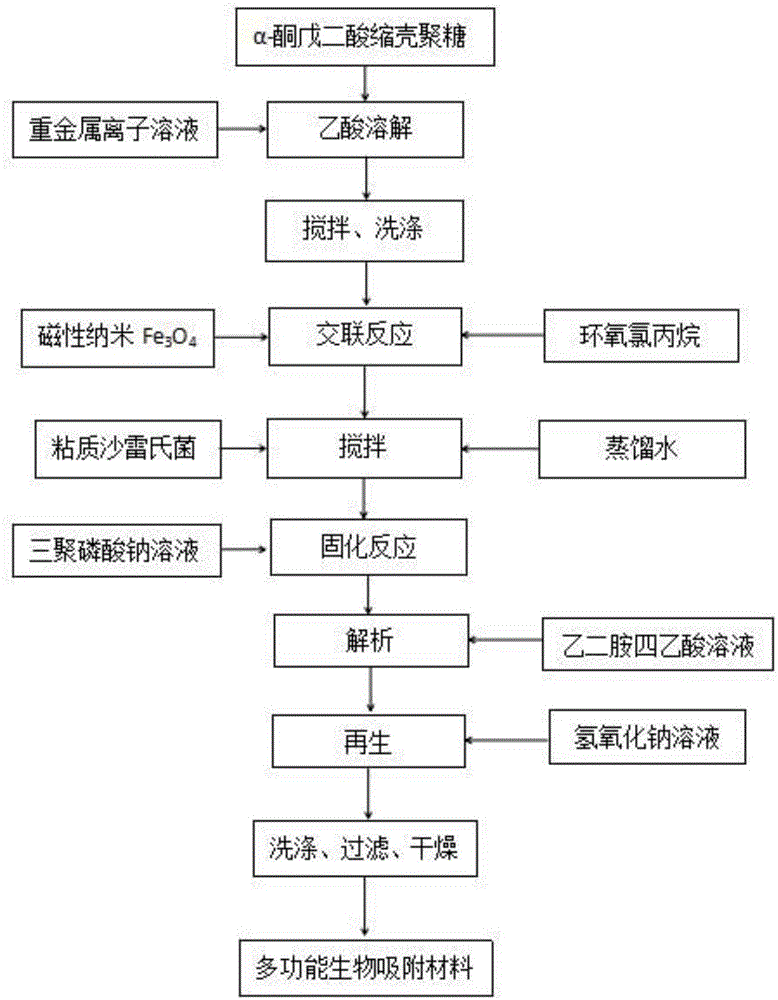

[0038] A kind of multifunctional biosorbent material of the present invention, its preparation method comprises the following steps (as figure 2 shown):

[0039] (1) Preparation of α-ketoglutarate chitosan (KCTS): Weigh 4.500g of chitosan dry sample, fully swell with 120mL distilled water for more than 24h, weigh m(α-ketoglutarate):m( Chitosan)=1.6:1.0 alpha-ketoglutaric acid 7.200g, join in the sufficient swelling system of chitosan at room temperature, stir 1h, promptly obtain slightly yellow transparent viscous solution; With 0.1mol / Slowly adjust the pH of the filtrate system to 4.5-5.5 (preferably 5.0) with 1 L of sodium hydroxide solution to obtain a milky white viscous solution, then transfer it to a 500mL three-necked flask and continue to stir evenly. Control the reaction time to 4h; according to the molar number of n(sodium borohydride):n(α-ketoglutaric acid)=1.8:1.0, accurately weigh 3.360g of sodium borohydride, and prepare it into 30mL of NaBH 4 Solution, slowl...

Embodiment 2

[0053] A kind of multifunctional biosorbent material of the present invention, its preparation method comprises the following steps:

[0054] (1) Preparation of α-ketoglutarate chitosan (KCTS): Weigh 4.500g of chitosan dry sample, fully swell with 120mL distilled water for more than 24h, weigh m(α-ketoglutarate):m( Chitosan)=1.6:1.0 alpha-ketoglutaric acid 7.200g, join in the sufficient swelling system of chitosan at room temperature, stir 1h, promptly obtain slightly yellow transparent viscous solution; With 0.1mol / Slowly adjust the pH of the filtrate system to 4.5-5.5 (preferably 5.0) with 1 L of sodium hydroxide solution to obtain a milky white viscous solution, then transfer it to a 500mL three-necked flask and continue to stir evenly. Control the reaction time to 4h; according to the molar number of n(sodium borohydride):n(α-ketoglutaric acid)=1.8:1.0, accurately weigh 3.360g of sodium borohydride, and prepare it into 30mL of NaBH 4 Solution, slowly add dropwise to the ...

Embodiment 3

[0064] A kind of multifunctional biosorbent material of the present invention, its preparation method comprises the following steps:

[0065] (1) Preparation of α-ketoglutarate chitosan (KCTS): Weigh 4.500g of chitosan dry sample, fully swell with 120mL distilled water for more than 24h, weigh m(α-ketoglutarate):m( Chitosan)=1.6:1.0 alpha-ketoglutaric acid 7.200g, join in the sufficient swelling system of chitosan at room temperature, stir 1h, promptly obtain slightly yellow transparent viscous solution; With 0.1mol / Slowly adjust the pH of the filtrate system to 4.5-5.5 (preferably 5.0) with 1 L of sodium hydroxide solution to obtain a milky white viscous solution, then transfer it to a 500mL three-necked flask and continue to stir evenly. Control the reaction time to 4h; according to the molar number of n(sodium borohydride):n(α-ketoglutaric acid)=1.8:1.0, accurately weigh 3.360g of sodium borohydride, and prepare it into 30mL of NaBH 4 Solution, slowly add dropwise to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com