Filler used for tower and capable of making gas and liquid in rotational flow contact and liquid and liquid in rotational flow contact

A gas-liquid, single-spin technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of promoting mixing, simple and easy processing and manufacturing, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

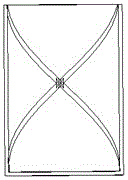

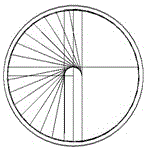

[0030] A new type of metal packing for towers that can make gas-liquid or liquid-liquid swirl contact, using figure 1 , figure 2 In the single blade structure shown, the length of the outer sleeve is 35 mm, the outer diameter is 35 mm, and the wall thickness is 1 mm. The twist blades have a diameter of 33 mm and a length of 35 mm. The twist angle is 180°. The outer sleeve is welded and fixed together with the twisted blades. The stacking number is 19000 pieces / m 3 . Random piles are installed in column equipment. It can be used in atmospheric distillation towers in refineries.

Embodiment 2

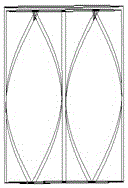

[0032] A new type of porcelain packing for towers that can make gas-liquid or liquid-liquid swirl contact, using image 3 , Figure 4 The double blades shown in the same direction structure, the length of the outer sleeve is 25mm, the outer diameter is 25mm, and the wall thickness is 1.5mm. The twist blades have a diameter of 11 mm and a length of 25 mm. The twist angle is 180°. The outer sleeve and the twisted vane are formed by sintering and fixed together. The stacking number is 42000 pieces / m 3 . Random piles are installed in column equipment. It can be used in the absorption tower in the hydrochloric acid process, and the porcelain packing can resist hydrochloric acid corrosion.

Embodiment 3

[0034] A new type of plastic packing for towers that can make gas-liquid or liquid-liquid swirl contact, using Figure 5 , Figure 6 The shown double blade reverse structure, the length of the outer sleeve is 25mm, the outer diameter is 25mm, and the wall thickness is 1.5mm. The twist blades have a diameter of 11 mm and a length of 25 mm. The twist angle is 180°. The outer sleeve and the twisted vanes are fixed together by extrusion. The stacking number is 48500 pieces / m 3 . Random piles are installed in column equipment. It can be used in the absorption tower of ammonia and carbon dioxide in the urea production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com