Dust treatment device used in ore processing

A technology for dust treatment and ore, which is applied in the direction of gas treatment, combined devices, and separation of dispersed particles, can solve problems such as soil and air pollution, water pollution, and ecological environment damage, achieving remarkable purification effects, purifying the environment, and ensuring physical health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

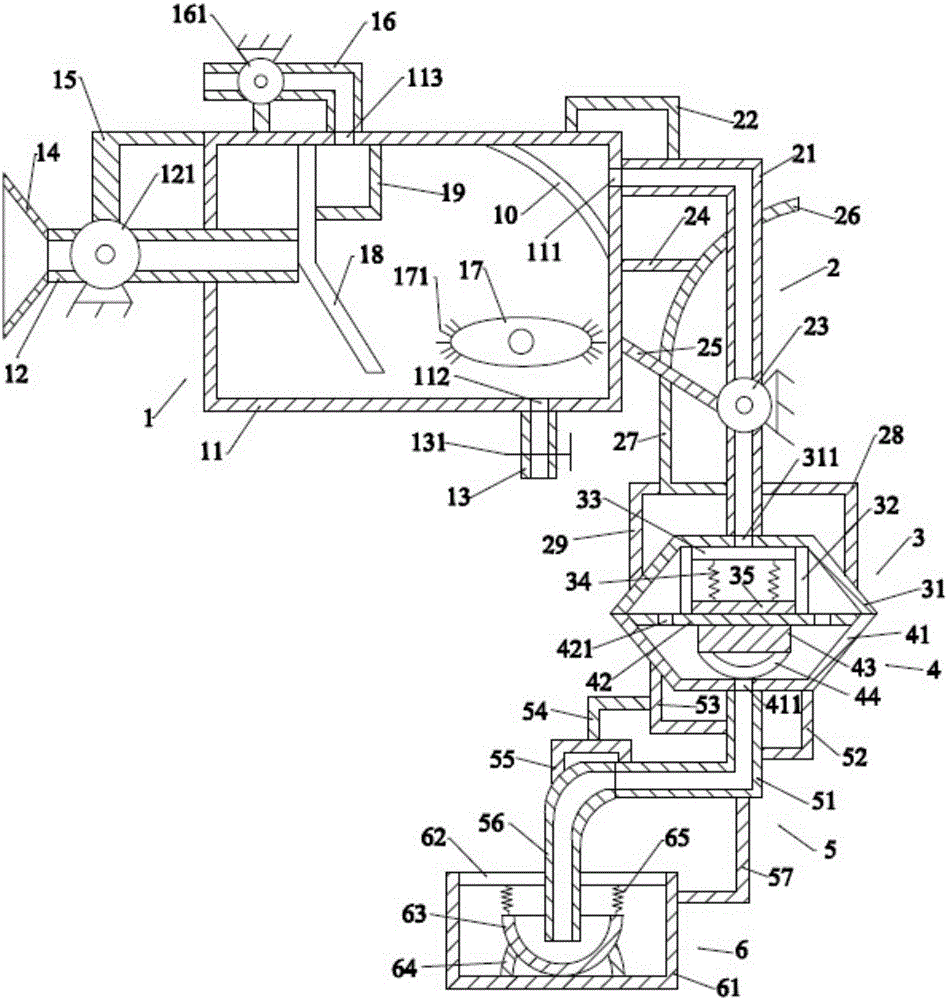

[0019] Such as figure 1 As shown, the dust treatment device in ore processing of the present invention includes an air extraction device 1, a pipeline device 2 located on the right side of the air extraction device 1, a first filter device 3 located below the pipeline device 2, and a first filter device 3 located at the first The second filter device 4 below the filter device 3 , the connection device 5 below the second filter device 4 , and the purification device 6 below the connection device 5 .

[0020] Such as figure 1 As shown, the air extraction device 1 includes a first frame body 11, a first pipeline 12 arranged on the first frame body 11, an air intake hopper 14 located on the left side of the first pipeline 12, and a The first support 15 on the top of the first pipeline 12, the second pipeline 16 above the first frame body 11, the first roller 17 accommodated in the first frame body 11, and the left side of the first roller 17. The first filter screen 18 on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com