A method of producing a co-crystal and a product formed through the method

A technology of products and substances, applied in the selection of auxiliary crystallization conditions, drug combination, solution crystallization, etc., to achieve the effect of high yield and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

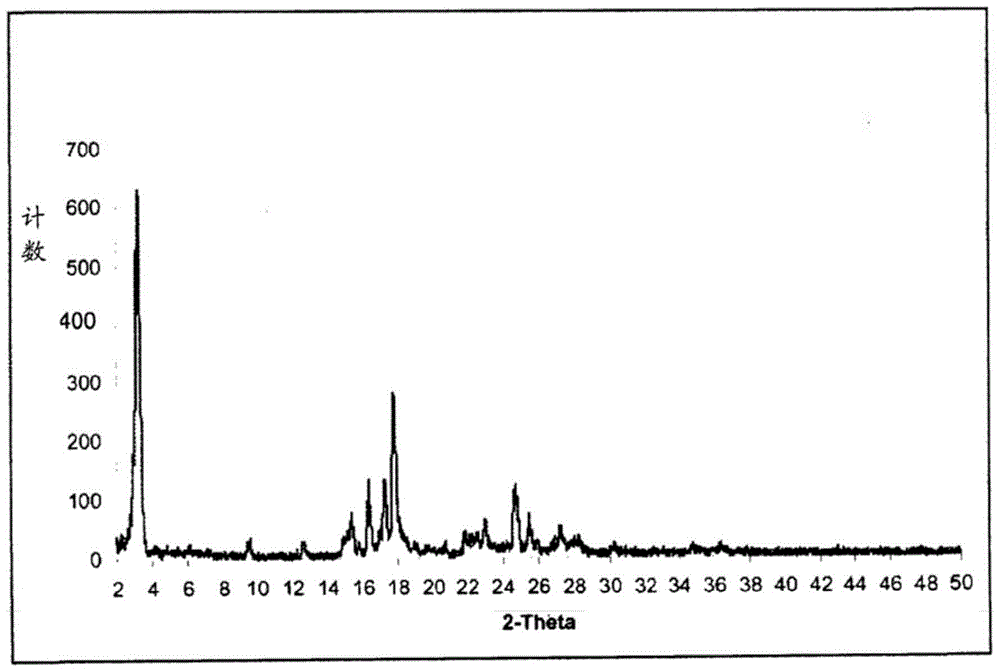

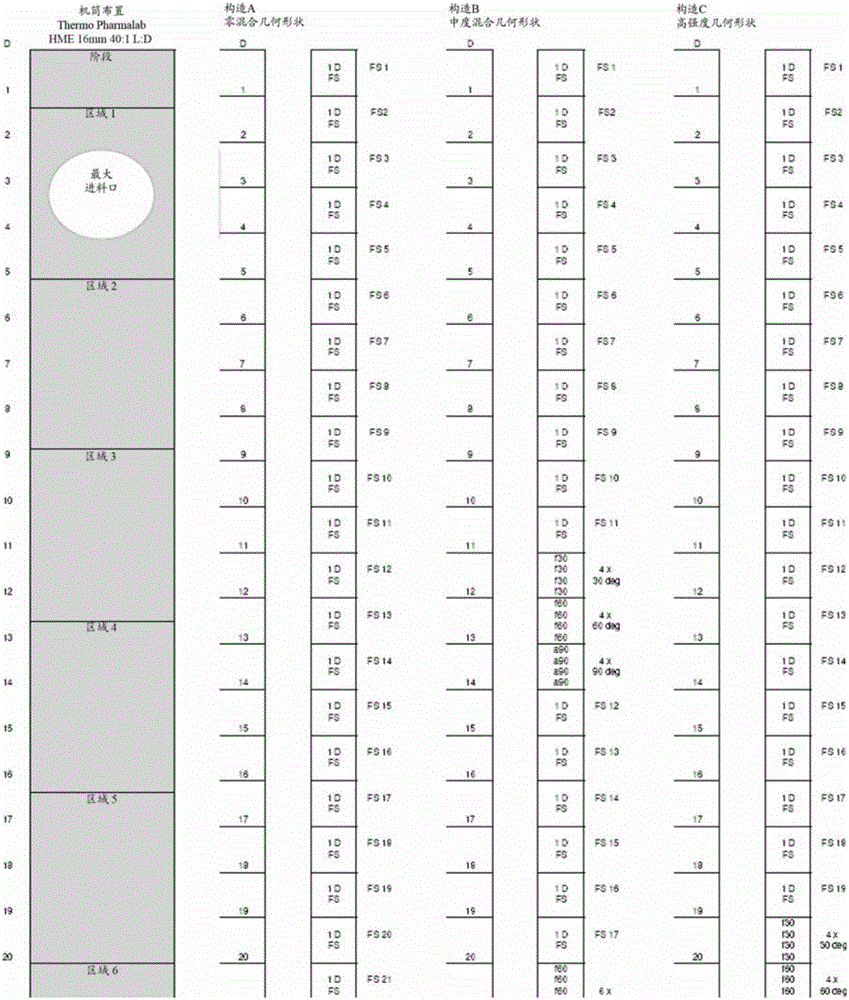

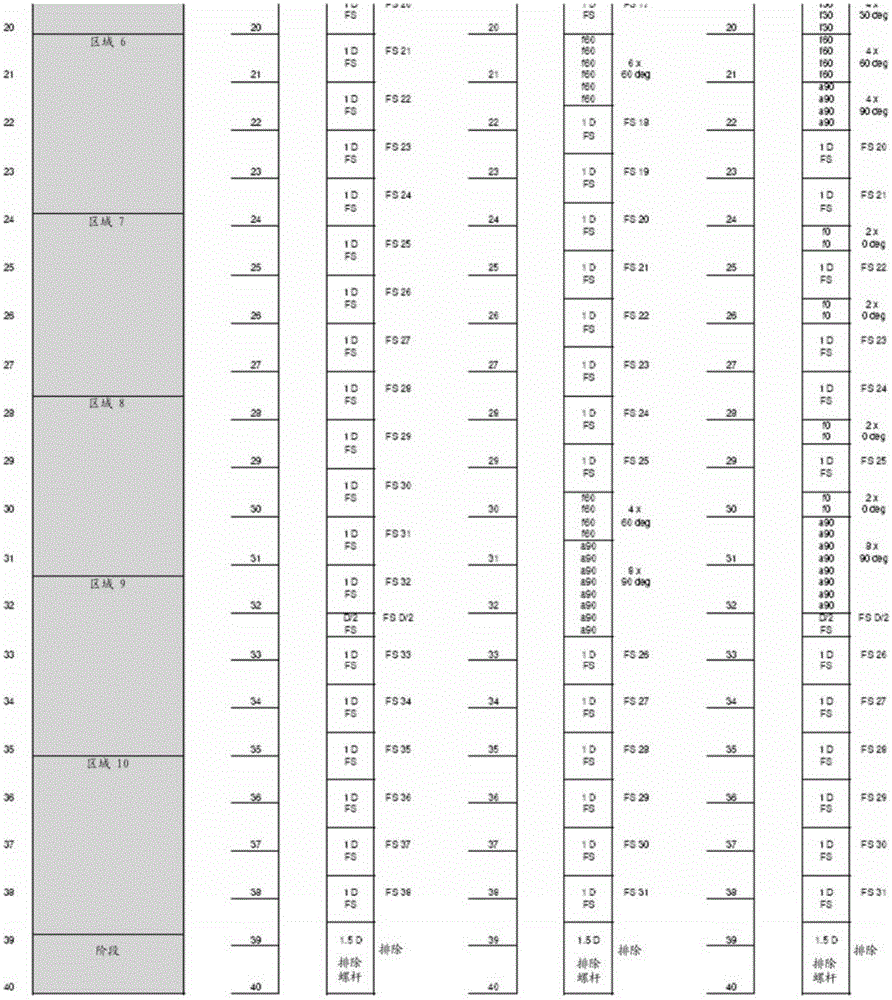

[0154] A physical mixture of ibuprofen and niacinamide was prepared by mixing 41.2 g of ibuprofen and 26 g of niacinamide (1:1 molar ratio) in a Turbula mixer for 30 minutes. An extruder (ThermoPrism TSE16TC) with an L:D ratio of 15:1 and a screw diameter of 16 mm was used. This incorporated screw configuration 1 mainly consists of a forward feed section and a small distributive mixing zone. The detailed screw configuration has been described previously. The barrel temperature was set at 80°C. Once the temperature stabilized for 15 min, the physical mixture was slowly fed to the extruder with the screw rotating at 20 rpm. Fine agglomerated product was collected at the exit of the extruder. The residence time of the material through the extruder was about 3 minutes. The powder was cooled to room temperature and then characterized by powder X-ray diffraction (PXRD).

[0155] figure 2 The PXRD pattern of a physical mixture comprising ibuprofen-nicotinamide is shown. The c...

example 2

[0158] A physical mixture of ibuprofen and niacinamide was prepared by mixing 41.2 g of ibuprofen and 26 g of niacinamide (1:1 molar ratio) in a Turbula mixer for 30 minutes. An extruder (ThermoPrism Eurolab) with an L:D ratio of 40:1 and a screw diameter of 16 mm was used. This incorporated screw configuration number 2 consists of feed and distributive mixing zones. The detailed screw configuration has been described previously. The barrel temperature was set at 80°C. Once the temperature stabilized for 15 min, the physical mixture was slowly fed to the extruder with the screw rotating at 20 rpm. The residence time of the material through the extruder was about 20 minutes. Fine agglomerated product was collected at the exit of the extruder. The powder was cooled to room temperature and then characterized by powder X-ray diffraction (PXRD).

[0159] As mentioned above, figure 2 The PXRD pattern of a physical mixture comprising ibuprofen-nicotinamide is shown. The chara...

example 3

[0162] A physical mixture of ibuprofen and niacinamide was prepared by mixing 41.2 g of ibuprofen and 26 g of niacinamide (1:1 molar ratio) in a Turbula mixer for 30 minutes. with an L:D ratio of 40:1, (ThermoPrismEurolab) with replaceable feed, distribution and dispersive mixing screw zones, and with a reverse feed screw section before the last feed zone (configuration 3) The temperature of the extruder was set at 80°C. Once the temperature stabilized for 15 min, the physical mixture was slowly fed to the extruder with the screw rotating at 20 rpm. The residence time of the material through the extruder was about 33 minutes. Fine agglomerated product was collected in the terminal region. The powder was cooled to room temperature and then characterized by powder X-ray diffraction (PXRD).

[0163] As mentioned above, figure 2 The PXRD pattern of a physical mixture comprising ibuprofen-nicotinamide is shown. The characteristic peak of ibuprofen can be observed at 6°2theta....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com