Detachable pedicle screw

A pedicle screw and detachable technology, applied in the field of pedicle screws, can solve the problems of increasing the economic burden of patients, increasing the pain of patients, hindering the reconstruction of trabecular bone, etc., to restore the structure and mechanical conduction characteristics, and avoid pain. and economic burden, and the effect of reducing the incidence of complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

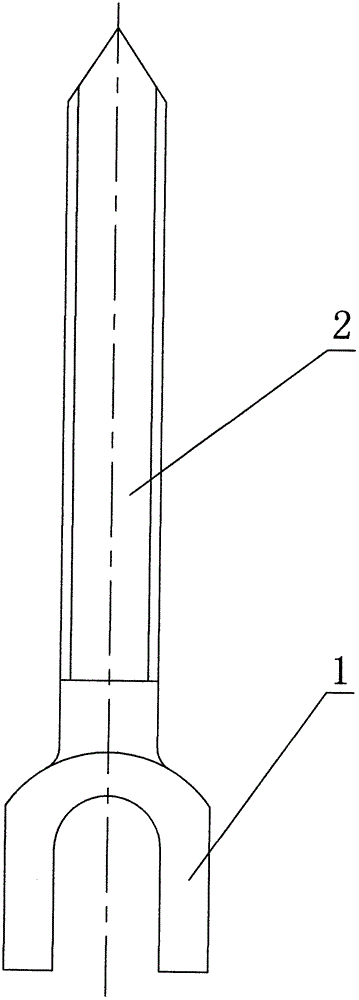

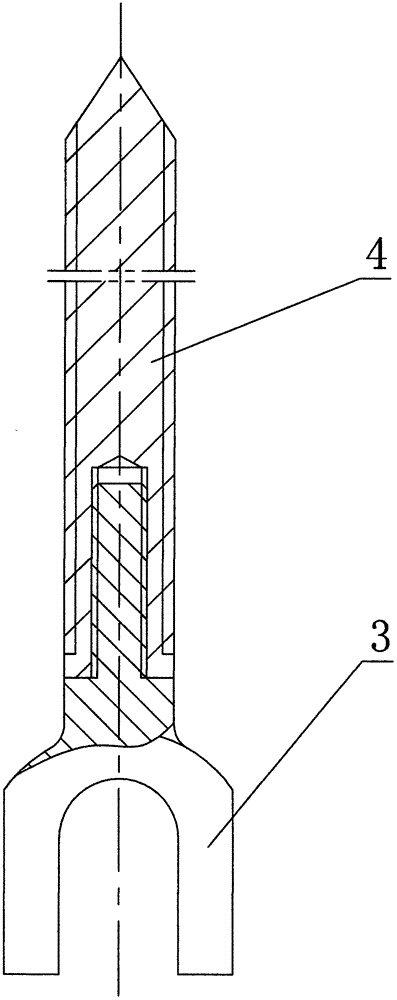

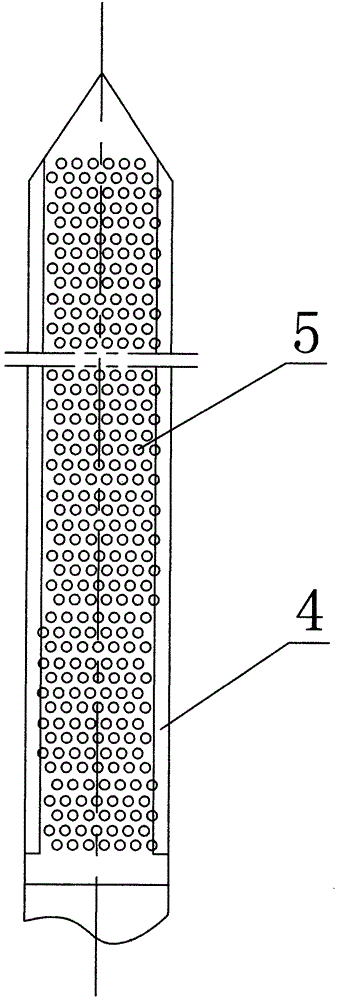

[0023] Embodiment 1: The present invention is an improvement to the existing one-piece pedicle screw, and the structure of the existing pedicle screw is as follows figure 1 As shown, its structure is an integrated structure of the screw body 2 and the nail tail 1 at the end of the screw body 2. The improved detachable screw body and the nail tail are split structures, such as figure 2 , image 3 As shown, a screw hole is provided at the axis of the end of the screw body 4, the screw rod protruding from the front end of the screw tail 3 is screwed with the screw body 4, and micro holes are evenly opened on the screw body 4 and the front end of the nail tail 5. The diameter of the microhole 5 is 1-50um, and the axis of the microhole 5 is perpendicular to the axis of the screw body 4 . After the pedicle screw with the structure of this embodiment is screwed into the pedicle, the axis of the microhole 5 on the screw body 4 is the same as the direction of the trabecular bone in t...

Embodiment 2

[0024] Embodiment 2: as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the screw body 4 and the front end of the nail tail are uniformly provided with strip-shaped holes 6, and the axis of the strip-shaped holes 6 is perpendicular to the axis of the screw body. After screwing the pedicle screw of the structure of this embodiment into the pedicle, the axis of the strip-shaped hole 6 on the screw body 4 is the same as the direction of the bone trabecula in the vertebral body, and the strip-shaped opening at the front end of the nail tail 3 is The axis of the hole 6 is the same as the direction of the trabecular bone in the vertebral body, so that the trabecular bone can be distributed along the strip-shaped hole 6 .

Embodiment 3

[0025] Embodiment 3: as Figure 5 , Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that a regular hexagonal groove 7 is provided at the end axis of the screw body 4, a screw hole is provided at the end axis of the screw body 4, and the nail tail 3 and The 4 screw nail bodies are screwed together. Screw the screw body 4 of the structure of the present embodiment into the pedicle with an external hexagonal wrench and adjust the axis of the microhole 5 (or strip hole 6) on the surface to be the same as the direction of the trabecular bone in the vertebral body, and then screw it into the pedicle. Screw tail 3, and make the axis of the microhole 5 (or strip hole 6) provided at the front end of the nail tail 3 be the same as the direction of the trabecular bone in the vertebral body, then the insertion of the pedicle screw with the structure of this embodiment is completed .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com