Garlic washing machine

A washing machine and garlic technology, which is applied in applications, food processing, climate change adaptation, etc., can solve the problems of unqualified finished products and difficult to meet the needs of garlic production, etc., and achieve the effect of strong practicability, reasonable design, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

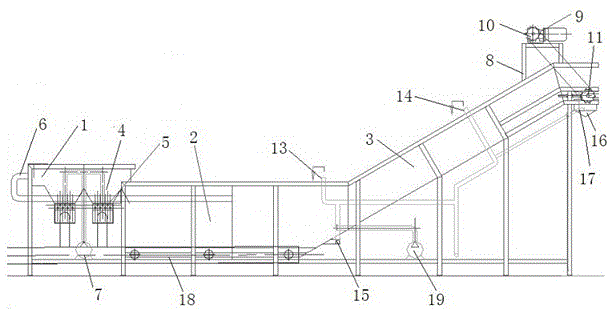

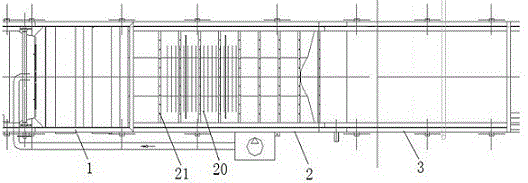

[0017] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a filter tank housing 1, a cleaning tank housing 2 and a transmission housing 3, and is characterized in that: a filter tank 4 is provided inside the filter tank housing 1, and a filter screen 5 is provided at the bottom end of the filter tank 4 The filter tank housing 1 at the lower end of the filter screen 5 is connected with a sewage pipe 18; the upper part of the filter tank housing 1 is provided with a preliminary flushing port 6; the filter tank 4 is connected with a circulating water pump I7 through a water pipe; the filter tank housing The body 1 is connected with the cleaning tank housing 2; the cleaning tank housing 2 is welded with the inclined upward transmission housing 3; the upper end of the transmission housing 3 is provided with a bracket 8, and a motor 9 is fixed on the bracket 8; The motor 9 is connected with a transmission gear I10, and the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com