Numerically-controlled machine tool thermal error on-line compensation method and system

A technology of numerical control machine tools and compensation methods, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as complex implementation process, high hardware cost, and large dependence on Siemens, and achieve convenient operation, strong real-time performance, The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

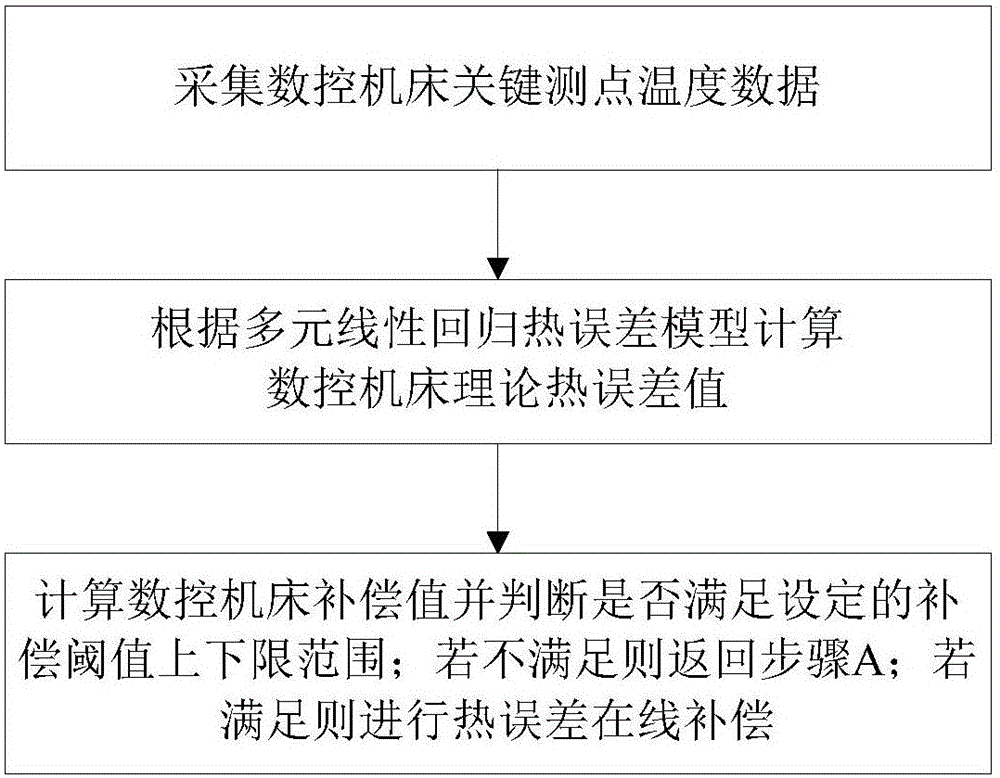

[0032] Such as figure 1 As shown, it is a schematic flow diagram of the method for online compensation of thermal errors of a numerically controlled machine tool of the present invention. An online compensation method for thermal error of a numerical control machine tool, including the following steps:

[0033] A. Collect temperature data at key measurement points of CNC machine tools;

[0034] B. Input the key measurement point temperature data collected in step A into the multiple linear regression thermal error model to calculate the theoretical thermal error value of the numerical control mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com