Preparation method of carboxymethylated Semen Cassiae gum reactive dye printing paste

A technology of carboxymethyl cassia and reactive dyes, which is applied in the field of reactive dye printing pastes, can solve the problems of small degree of substitution, poor mesh penetration, and many insolubles in cold water, and achieve improved water solubility, improved mesh permeability, and industrial value. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

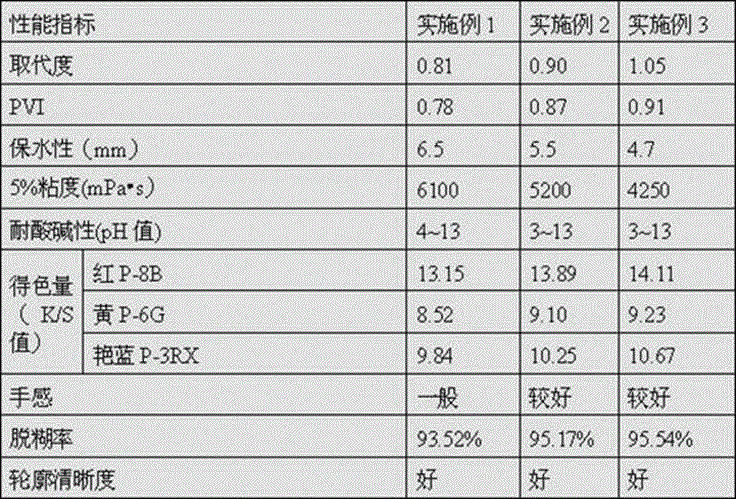

Examples

Embodiment 1

[0018] The preparation method of the carboxymethyl cassia gum reactive dye printing paste of the present embodiment may further comprise the steps:

[0019] (1) Cool 53.3g of sodium hydroxide solution with a mass fraction of 45% (sodium hydroxide 24g, 0.6mol) to room temperature, and add it to 100mL of stirring ethanol (95%) to obtain an ethanol solution of sodium hydroxide, Under stirring, add 50 g of cassia seed rubber powder to the ethanol solution of sodium hydroxide, and alkalize at 28°C for 60 minutes;

[0020] (2) After the alkalization reaction, add chloroacetic acid (29g, 0.3mol), stir well, then raise the temperature to 65°C for etherification reaction for 3.5h;

[0021] (3) After the etherification reaction, lower the temperature to 28°C, adjust the pH of the reaction system to neutral with hydrochloric acid, wash, filter with suction, dry at 80°C, and pulverize to obtain carboxymethyl cassia gum reactive dye printing paste, which replaces The degree is 0.8.

Embodiment 2

[0023] The preparation method of the carboxymethyl cassia gum reactive dye printing paste of the present embodiment may further comprise the steps:

[0024] (1) Cool 88g of sodium hydroxide solution with a mass fraction of 45% (containing 39.6g of sodium hydroxide, 0.99mol) to room temperature, and add it to 125mL of stirring ethanol (95%) to obtain an ethanol solution of sodium hydroxide , under stirring, add 50g of cassia seed rubber powder to the ethanol solution of sodium hydroxide, and alkalize the reaction for 30min at 32°C;

[0025] (2) After the alkalization reaction, add chloroacetic acid (42.5g, 0.45mol), stir well, then raise the temperature to 75°C, and carry out the etherification reaction for 3 hours;

[0026] (3) After the etherification reaction, lower the temperature to 32°C, adjust the pH of the reaction system to neutral with hydrochloric acid, wash, filter with suction, dry at 80°C, and pulverize to obtain carboxymethyl cassia gum reactive dye printing past...

Embodiment 3

[0028] The preparation method of the carboxymethyl cassia gum reactive dye printing paste of the present embodiment may further comprise the steps:

[0029] (1) Cool 74.7g of sodium hydroxide solution with a mass fraction of 45% (containing 33.6g of sodium hydroxide, 0.84mol) to room temperature, and add it to 110mL of stirring ethanol (95%) to obtain ethanol for sodium hydroxide solution, under stirring, add 50g of cassia seed rubber powder to the ethanol solution of sodium hydroxide, and alkalize the reaction for 45min at 30°C;

[0030] (2) After the alkalization reaction, add chloroacetic acid (37.8g, 0.4mol), stir well, then raise the temperature to 70°C, and carry out etherification reaction for 3.2h;

[0031] (3) After the etherification reaction, lower the temperature to 30°C, adjust the pH of the reaction system to neutral with hydrochloric acid, wash, filter with suction, dry at 80°C, and pulverize to obtain carboxymethyl cassia gum reactive dye printing paste, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com