Industrial sewing machine with built-in stator winding

A technology for industrial sewing machines and stator windings, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of inconvenient transportation, complicated assembly, and high cost, and achieve easy transportation and installation, prevent overheating of power sources, and reduce occupation. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, an industrial sewing machine with a built-in stator winding as an example of the present invention will be described based on the drawings.

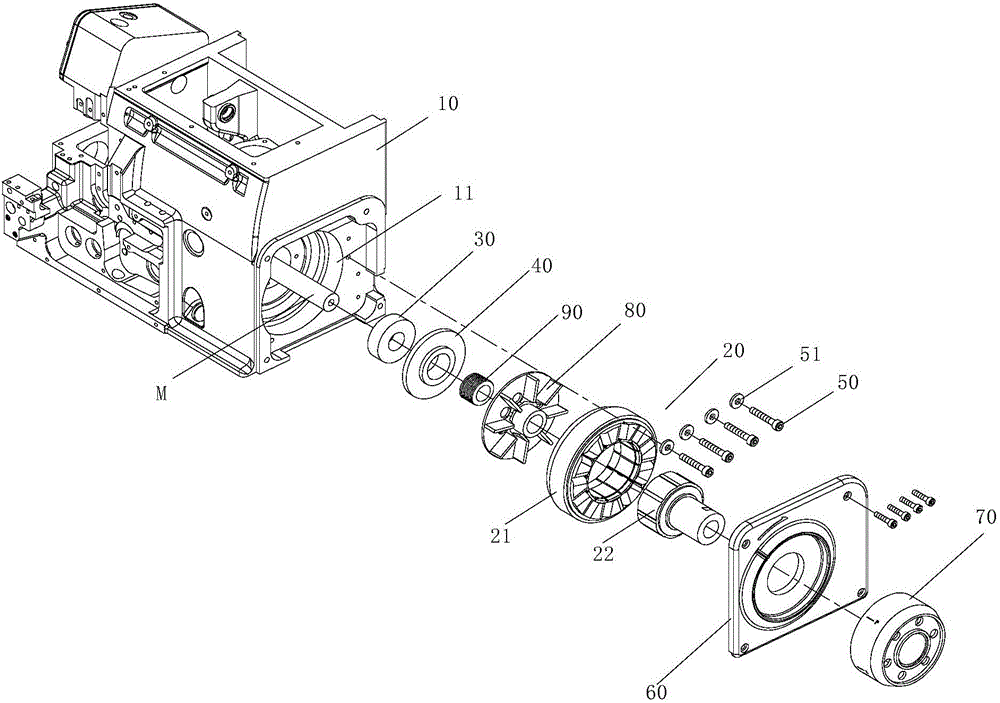

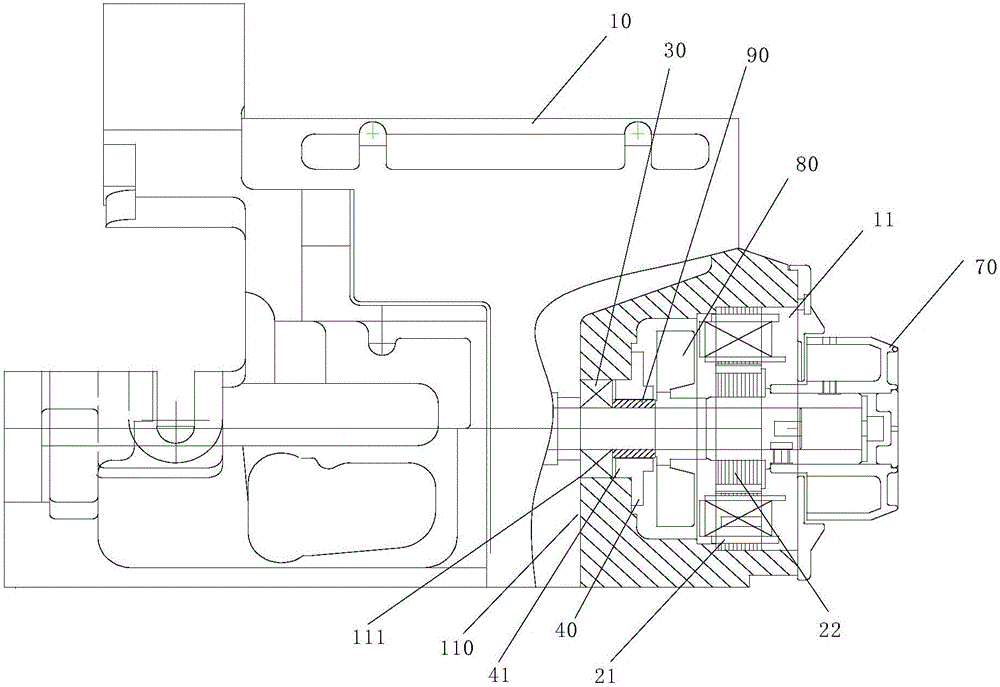

[0020] figure 1 It is an exploded perspective view showing the stator winding built-in industrial sewing machine of the present invention. figure 2 It is a partial sectional schematic diagram showing the stator winding built-in industrial sewing machine of the present invention.

[0021] Such as figure 1 , figure 2 As shown, the stator winding built-in industrial sewing machine has a casing 10 and a driving device 20 embedded in the casing 10 , and the driving device 20 is composed of a stator winding 21 and a rotor 22 .

[0022] Specifically, the housing 10 is integrally cast with the housing 10 to form an accommodating chamber 11. The accommodating chamber 11 is formed at one end in the extending direction of the main shaft M of the sewing machine. cylindrical shape. A bearing mounting hole 111 is formed in a chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com