A kind of high-performance hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy, high-performance technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., to achieve superior performance, large degree of freedom of regulation, and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

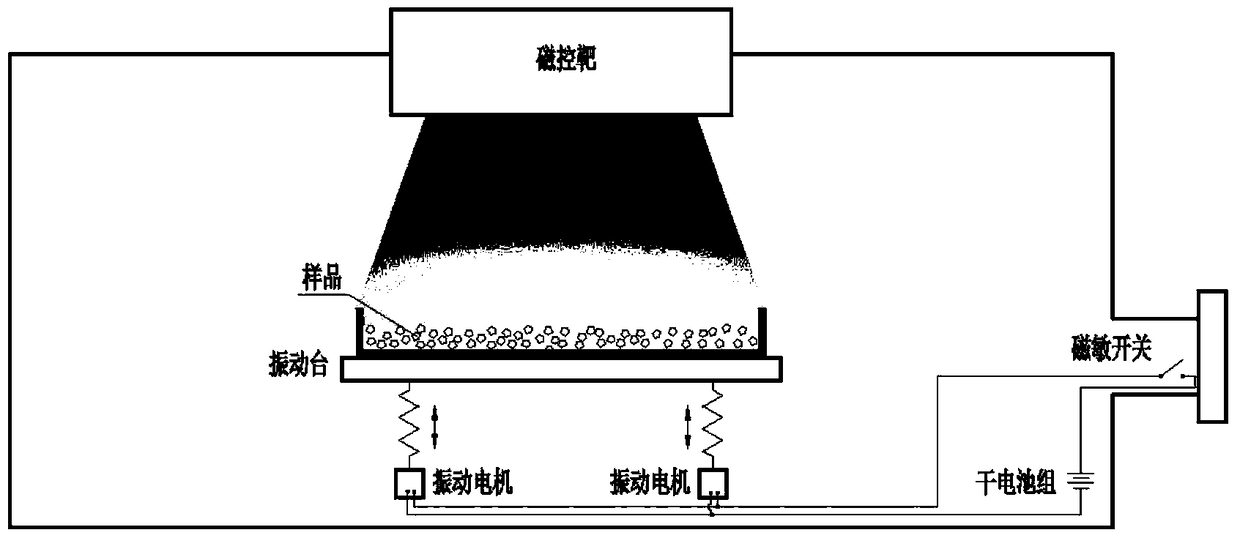

Method used

Image

Examples

Embodiment 1

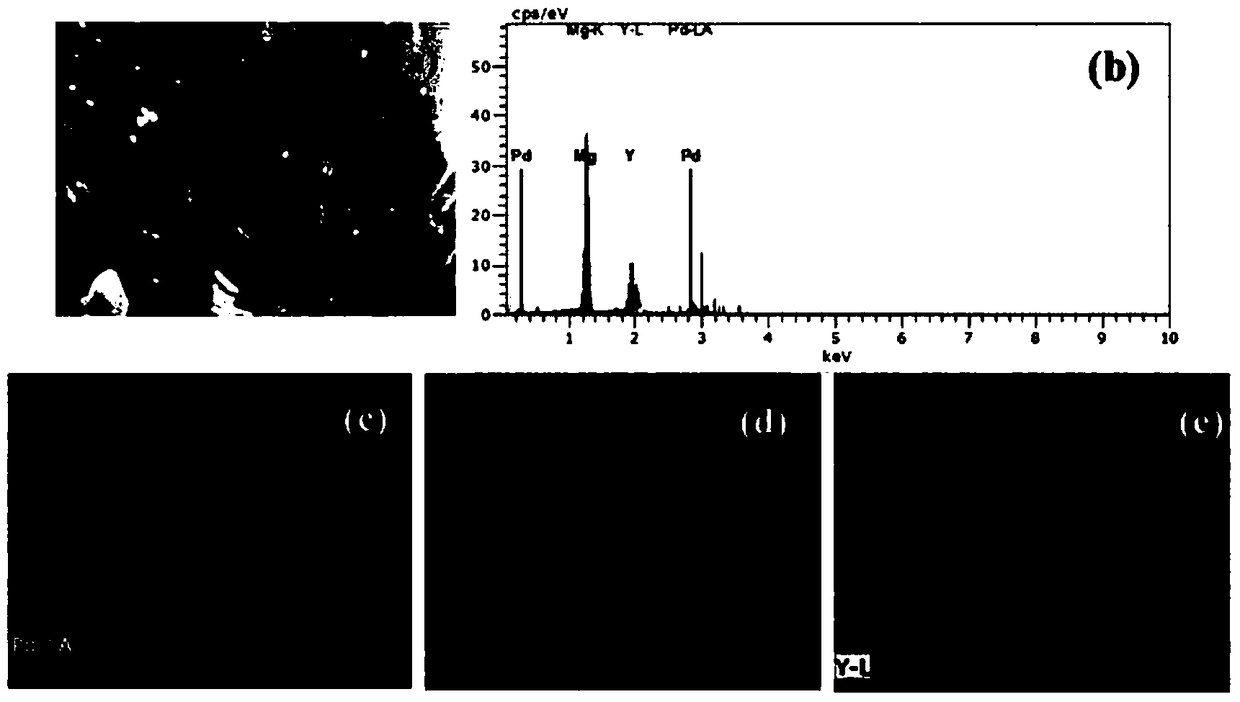

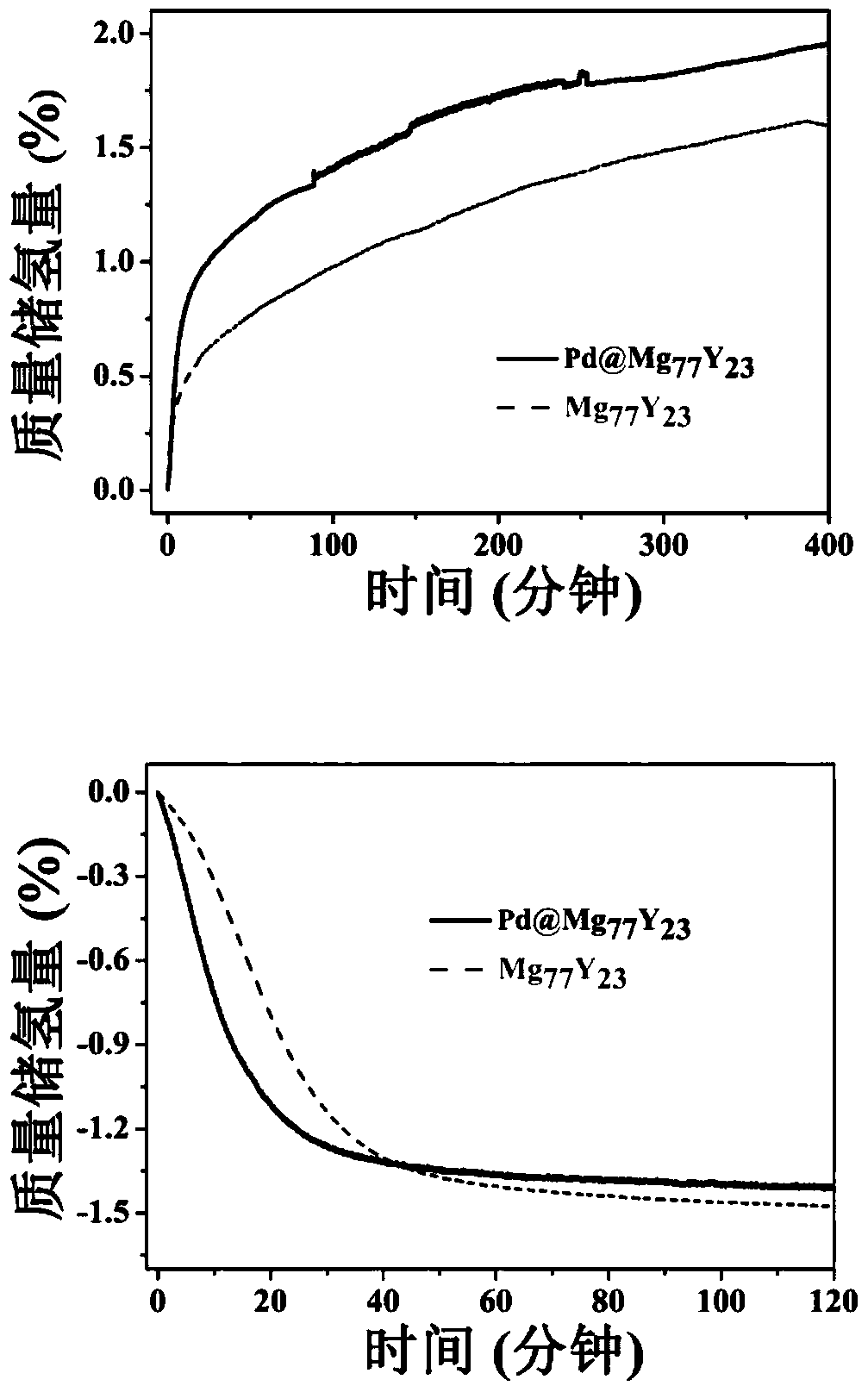

[0028] The particle size of the prepared particles is 60-80μm, the thickness of the coated Pd film is 5nm, and the composition is Pd@Mg 77 Y 23 hydrogen storage alloy

[0029] 1) Ingredients

[0030] Use metal Mg and metal Y with a purity of more than 99.5% according to the design composition Mg 77 Y 23 Carry out batching, and consider certain burning loss (the burning loss of Y is set as 5wt%, Mg burning loss 15wt%);

[0031] 2) Alloy melting

[0032] The Mg-Y master alloy was prepared by high-vacuum high-frequency induction melting furnace. Put the raw materials prepared in step 1) in the graphite crucible of the high-vacuum high-frequency induction melting furnace, and evacuate until the background vacuum degree is higher than 5×10 -4 Pa, and then wash the furnace chamber with argon gas with a purity ≥ 99.999% for 3 times, and then start heating: first turn on the power to preheat the crucible for 20 seconds, then adjust the current to 120A to completely melt the allo...

Embodiment 2

[0041] The particle size of the prepared particles is 100-120μm, the thickness of the coated Pd film is 10nm, and the composition is Pd@Mg 77 Y 23 hydrogen storage alloy

[0042] 1) Ingredients

[0043] Use metal Mg and metal Y with a purity of more than 99.5% according to the design composition Mg 77 Y 23 Carry out batching, and consider certain burning loss (the burning loss of Y is set as 5wt%, Mg burning loss 15wt%);

[0044] 2) Alloy melting

[0045] The Mg-Y master alloy was prepared by high-vacuum high-frequency induction melting furnace. Put the raw materials prepared in step 1) in the graphite crucible of the high-vacuum high-frequency induction melting furnace, and evacuate until the background vacuum degree is higher than 5×10 -4 Pa, and then wash the furnace chamber with argon gas with a purity ≥ 99.999% for 3 times, and then start heating: first turn on the power to preheat the crucible for 20 seconds, then adjust the current to 120A to completely melt the a...

Embodiment 3

[0054] The particle size of the prepared particles is 60-80μm, the thickness of the coated Pd film is 20nm, and the composition is Pd@Mg 77 Y 23 hydrogen storage alloy

[0055] 1) Ingredients

[0056] Use metal Mg and metal Y with a purity of more than 99.5% according to the design composition Mg 77 Y 23 Carry out batching, and consider certain burning loss (the burning loss of Y is set as 5wt%, Mg burning loss 15wt%);

[0057] 2) Alloy melting

[0058] The Mg-Y master alloy was prepared by high-vacuum high-frequency induction melting furnace. Put the raw materials prepared in step 1) in the graphite crucible of the high-vacuum high-frequency induction melting furnace, and evacuate until the background vacuum degree is higher than 5×10 -4 Pa, and then wash the furnace chamber with argon gas with a purity ≥ 99.999% for 3 times, and then start heating: first turn on the power to preheat the crucible for 20 seconds, then adjust the current to 120A to completely melt the all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com