Rare earth-doped nanometer spherical TiO2 up-conversion compound and preparation method thereof

A rare earth doping, rare earth chloride technology, applied in chemical instruments and methods, measuring devices, fluorescence/phosphorescence, etc., can solve the problems of affecting luminous efficiency, high phonon energy, rare earth doped oxides not nano-sized, etc. Achieve the effect of improving resolution, small size, and long luminous time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Take 3.6 mL of tetrabutyl titanate with a concentration of 0.966 g / mL and 1.08 mL of ethanolamine with a concentration of 1.02 g / mL and mix them evenly to obtain solution 1;

[0037] (2) 0.18mL deionized water, 7.2mL absolute ethanol, 15.3mL ErC1 with a concentration of 0.01mol / L 3 ·6H 2 O, concentration is 10.2mL ytterbium nitrate of 0.1mol / L, concentration is 4.08mLLiCl of 0.5mol / L, mixes and makes solution 2;

[0038] (3) Under continuous stirring, drop solution 2 into solution 1 drop by drop, and keep stirring to obtain uniform and transparent doped TiO 2 Sol;

[0039] (4) Put this solution into the polytetrafluoroethylene lining of a 50mL autoclave, heat it at 120°C for 6 hours and then cool it down to room temperature naturally. Dry in a constant temperature drying oven;

[0040] (5) Put the obtained luminescent powder into a crucible for annealing at 800° C. for 4 hours, and grind after cooling.

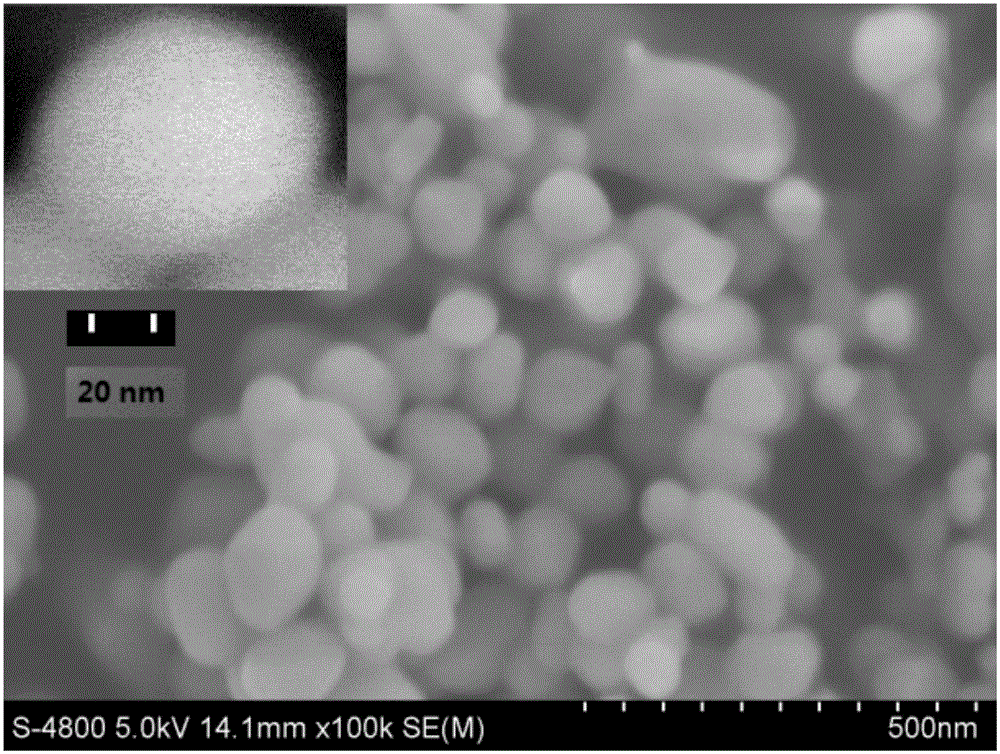

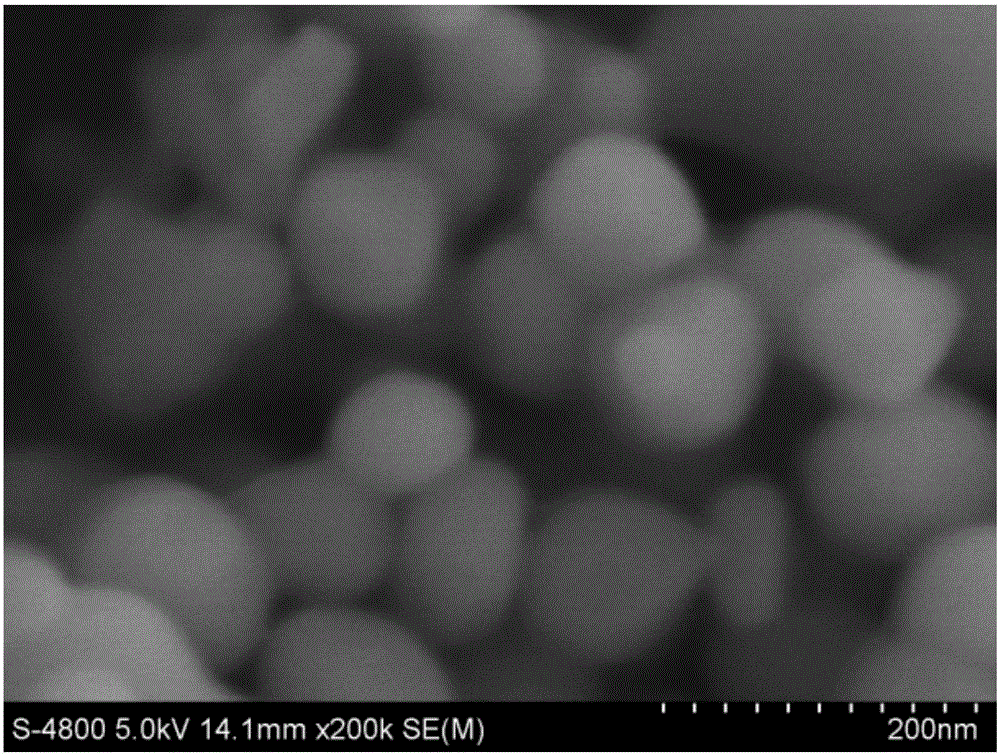

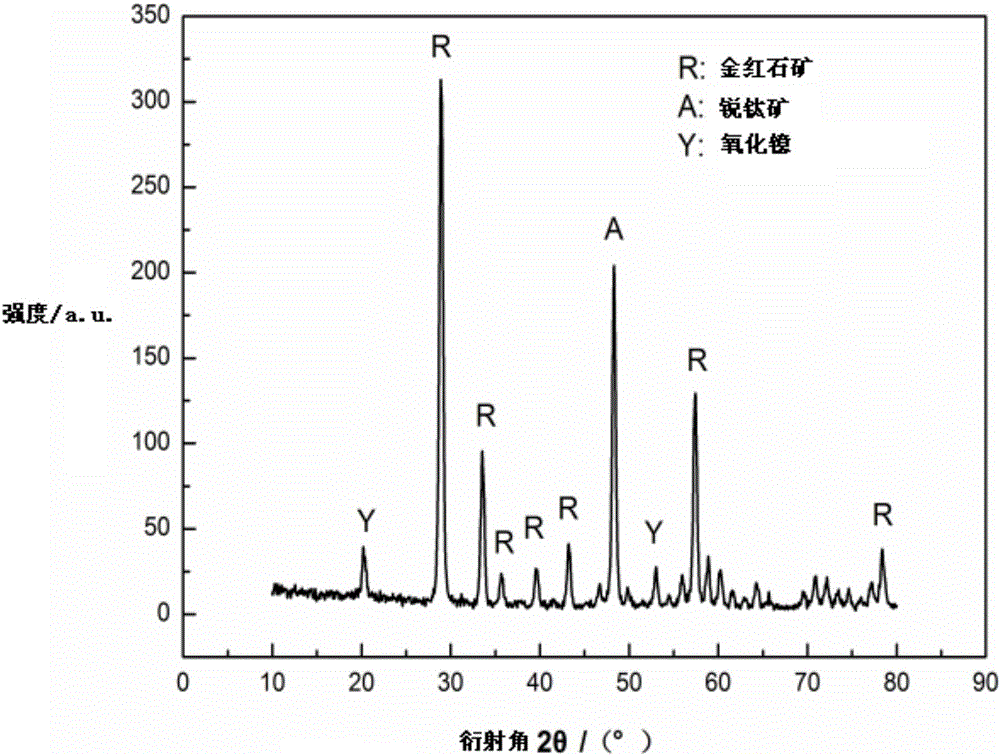

[0041] Rare earth-doped nano-spherical TiO made by the me...

Embodiment 2

[0043] (1) Weigh 5 mL of tetrabutyl titanate with a concentration of 0.966 g / mL and 6.8 mL of diethanolamine with a concentration of 1.097 g / mL, and mix them to obtain a mixed solution 1;

[0044] (2) 1.3mL deionized water, 10mL absolute ethanol, Ho(NO 3 ) 3 ·5H 2 O14.2mL, the concentration is 0.1mol / L of Yb(NO 3 ) 3 ·5H 2 O14.2mL, KCl2.84mL with a concentration of 0.5mol / L, mixed evenly to make solution 2;

[0045] (3) Under continuous stirring, drop solution 2 into solution 1 drop by drop, and keep stirring to obtain uniform and transparent doped TiO 2 Sol;

[0046] (4) Put this solution into the polytetrafluoroethylene lining of the autoclave, heat it at 90°C for 3 hours and then cool it down to room temperature naturally. drying in a drying oven;

[0047] (5) Put the obtained luminescent powder into a crucible for annealing at 900° C. for 2 hours, and grind after cooling.

[0048] Rare earth doped nano spherical TiO made by the method of embodiment 2 2 The chemical...

Embodiment 3

[0050] (1) Weigh 5 mL of tetrabutyl titanate with a concentration of 0.966 g / mL and 1.36 mL of diethanolamine with a concentration of 1.097 g / mL, and mix them to obtain a mixed solution 1;

[0051] (2) 0.5mL deionized water, 10mL absolute ethanol, Eu(NO 3 ) 3 ·5H 2 O17mL, the concentration is 0.1mol / L of Yb(NO 3 ) 3 5H 2 O14.2mL, concentration is 0.5mol / L NaCl1.42mL, mix uniformly and make solution 2;

[0052] (3) Under continuous stirring, drop solution 2 into solution 1 drop by drop, and keep stirring to obtain uniform and transparent doped TiO 2 Sol;

[0053] (4) Put this solution into the polytetrafluoroethylene lining of a 50mL autoclave, heat it at 120°C for 3 hours and then cool it down to room temperature naturally. Dry in a constant temperature drying oven;

[0054] (5) Put the obtained luminescent powder into a crucible for annealing at 600° C. for 4 hours, and grind after cooling.

[0055] Rare earth doped nano spherical TiO made by the method of embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com