High-quality explosive crystals prepared by self-assembling and preparation method thereof

A self-assembly, high-quality technology, applied in the direction of nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of low purity of high-quality explosive crystals, low yield of preparation methods, and difficult scale-up production, etc., to achieve The effect of short preparation cycle, low sensitivity and easy amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step (1): Weigh 20g of HMX explosive at room temperature, dissolve it in 150g of dimethyl sulfoxide to make a solution, place it in a high-pressure spray tank with a pressure of 0.55MPa, and spray the explosive solution under the action of 60kHz ultrasound Carry out crystallization in cold water at a temperature of 5°C, and centrifuge the resulting suspension to obtain HMX fine particle explosives;

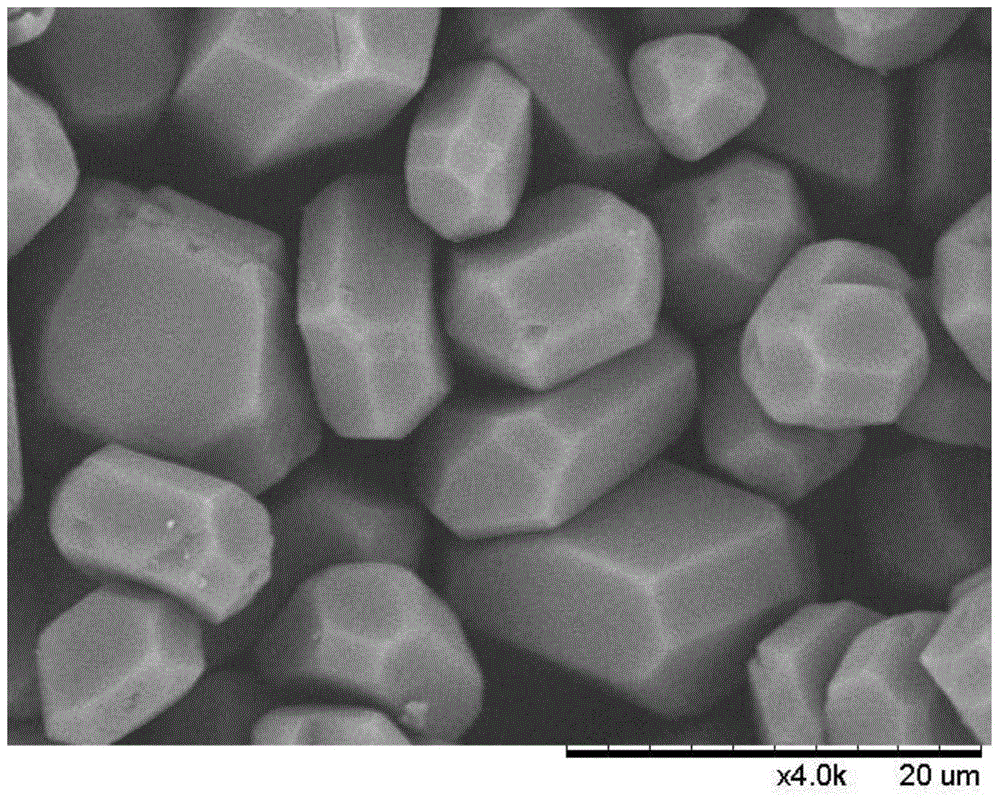

[0024] Step (2): Add the above-mentioned HMX fine particle explosive to a mixed solvent of water: acetone = 10:1 to form a suspension, pour it into a stainless steel reaction kettle, seal it, and use a heating rate of 5°C / min to program the temperature. Heating to 160°C, assembling reaction for 0.5h, cooling the reaction kettle, filtering, washing with deionized water, and drying to obtain high-quality explosive HMX crystals. figure 1 It is the scanning electron microscope image of the high-quality HMX explosive crystal obtained in this example, the particle shape is unifor...

Embodiment 2

[0026] Step (1): Weigh 20g of HMX explosive at room temperature, dissolve it in 80g of acetone to form a solution, place it in a high-pressure spray tank with a pressure of 0.68MPa, and spray the explosive solution to a temperature of 0.5 under the action of 120kHz ultrasonic waves. Crystallize in cold water at ℃, and centrifuge the resulting suspension to obtain HMX fine particle explosives;

[0027] Step (2): Add the above-mentioned HMX fine particle explosives into a mixed solvent of water: ethanol = 1:1 to form a suspension, pour it into a stainless steel reaction kettle, seal it, and use a heating rate of 1°C / min for temperature programming. Heating to 120°C, assembling for 3 hours, cooling the reaction kettle, filtering, washing with deionized water, and drying to obtain high-quality explosive HMX crystals. figure 2 The scanning electron microscope image of the high-quality HMX explosive crystal obtained in this example shows that the particle shape is uniform, the prod...

Embodiment 3

[0029] Step (1): Weigh 20g of LLM-105 explosive at room temperature, dissolve it in 200g of N,N-dimethylformamide to make a solution, put it in a high-pressure spray tank with a pressure of 0.52MPa, and under the action of 20kHz ultrasonic , spray the explosive solution into cold water at a temperature of 3°C for crystallization, and centrifuge the obtained suspension to obtain LLM-105 fine particle explosive;

[0030] Step (2): Add the above-mentioned LLM-105 fine particle explosive into a mixed solvent of water:N,N-dimethylformamide=500:1 to form a suspension, pour it into a stainless steel reaction kettle, seal it, and use 20°C / min heating rate for temperature programming, heating to 140°C, assembly reaction for 12 hours, cooling the reaction kettle, filtering, washing with deionized water, and drying to obtain high-quality explosive LLM-105 crystals. image 3 The scanning electron microscope image of the high-quality LLM-105 explosive crystal obtained in this example shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com