Magnesium oxysulfate cement plate and preparation method thereof

A technology of magnesium oxysulfide cement board and cement board, which is applied in the field of building materials, can solve the problems of reducing the service life of products, stagnation of glass magnesium board, and returning to halogen, and achieves the effects of avoiding halogen returning, good flexural strength and reasonable formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

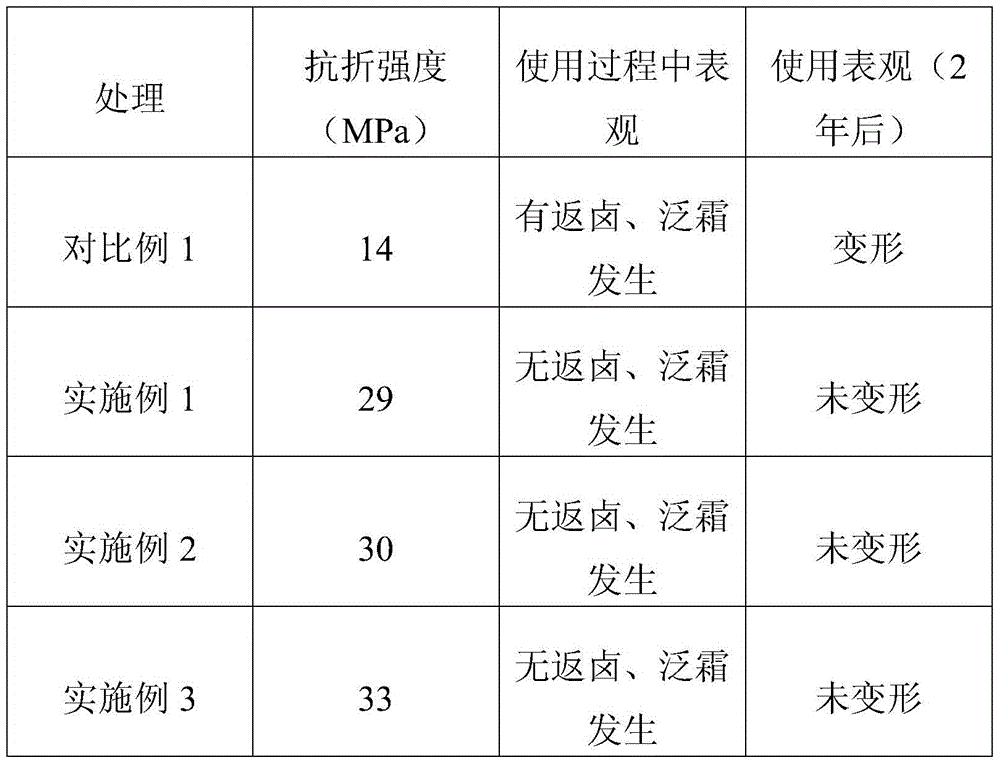

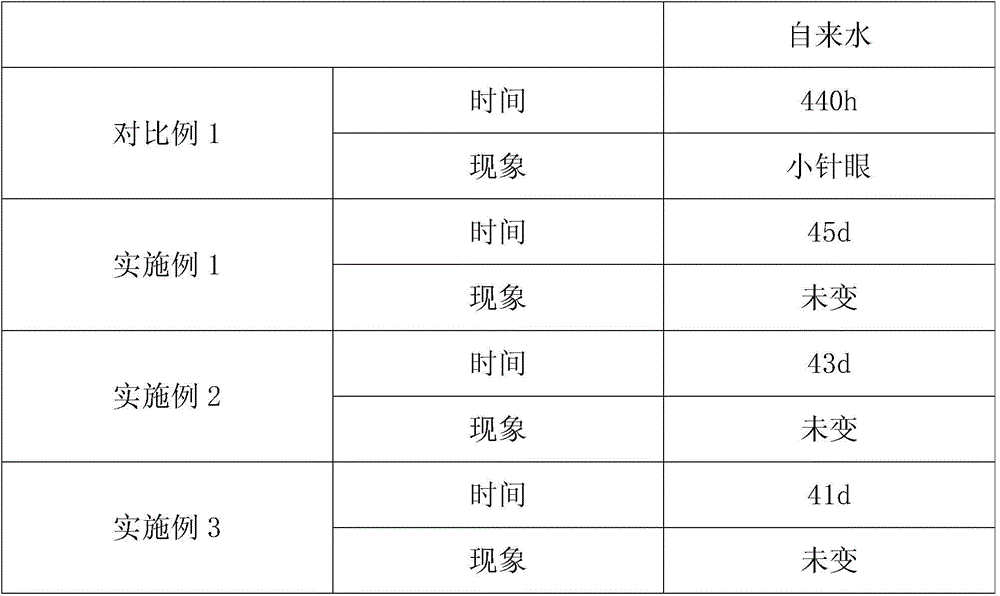

Examples

Embodiment 1

[0026] A magnesium oxysulfide cement board, comprising the following components by weight: 60 parts of magnesium oxide, 30 parts of magnesium sulfate solution, 8 parts of coarse wood powder, 6 parts of fine wood powder, 3 parts of reinforcing materials and 0.2 parts of modifier ; The purity of the magnesium oxide is 85%, and its activity is 62%; the concentration of the magnesium chloride solution is 22°Bé; the fineness of the coarse wood powder is 10 orders, and the fineness of the fine wood powder 40 mesh; the reinforcing material is fly ash; the modifier comprises the following components by weight: 3 parts of sodium butylnaphthalene sulfonate, 10 parts of ammonium carbonate, 5 parts of magnesium hydroxide, chlorine 5 parts of ammonium chloride and 1 part of sodium carboxymethylcellulose.

[0027] The preparation method of described magnesium oxysulfate cement board, comprises the following steps:

[0028] (1) Preparation of magnesium sulfate solution: start pre-preparatio...

Embodiment 2

[0034] A magnesium oxysulfate cement board, comprising the following components by weight: 75 parts of magnesium oxide, 40 parts of magnesium sulfate solution, 10 parts of coarse wood powder, 8 parts of fine wood powder, 6 parts of reinforcing material and 0.5 part of modifier ; The purity of the magnesium oxide is 95%, and its activity is 65%; the concentration of the magnesium chloride solution is 28°Bé; the fineness of the coarse wood powder is 20 orders, and the fineness of the fine wood powder 60 mesh; the reinforcing material is silica fume; the modifying agent comprises the following components by weight: 5 parts of sodium butylnaphthalene sulfonate, 15 parts of ammonium carbonate, 15 parts of magnesium hydroxide, chloride 8 parts of ammonium and 3 parts of sodium carboxymethylcellulose.

[0035] The preparation method of described magnesium oxysulfate cement board, comprises the following steps:

[0036] (1) Preparation of magnesium sulfate solution: start pre-prepara...

Embodiment 3

[0042] A magnesium oxysulfate cement board, comprising the following components by weight: 70 parts of magnesium oxide, 35 parts of magnesium sulfate solution, 9 parts of coarse wood powder, 7 parts of fine wood powder, 5 parts of reinforcing material and 0.4 part of modifier The purity of the magnesium oxide is 90%, and its activity is 63%; the concentration of the magnesium chloride solution is 25°Bé; the fineness of the coarse wood powder is 15 orders, and the fineness of the fine wood powder 50 mesh; the reinforcing material is slag; the modifier comprises the following components by weight: 4 parts of sodium butylnaphthalene sulfonate, 12 parts of ammonium carbonate, 10 parts of magnesium hydroxide, ammonium chloride 6 parts and 2 parts of sodium carboxymethylcellulose.

[0043] The preparation method of described magnesium oxysulfate cement board, comprises the following steps:

[0044] (1) Preparation of magnesium sulfate solution: start pre-preparation 2 days before u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com