Foldable electrothermal film device based on graphene

A technology of graphene and electric heating film, which is applied in the direction of graphene, electrical components, electric heating devices, etc., can solve the problems of insufficient size of graphene oxide, unclear flexibility, and inability to meet the rapid development of science and technology, so as to improve the electrical and thermal conductivity, wide The effect of applying potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A super-flexible graphene electrothermal film is prepared by using non-fragmented super-large graphene oxide.

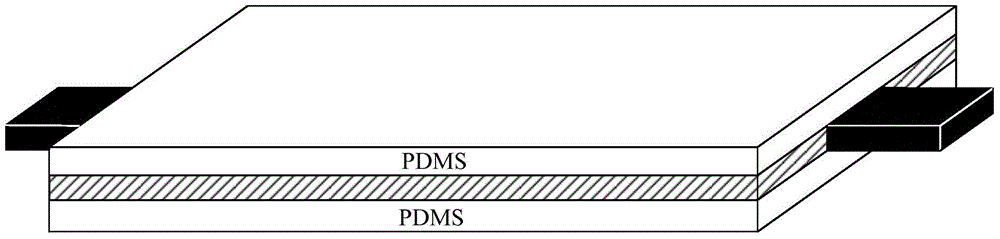

[0028] Graphene oxide with an average size larger than 100um was formulated into a graphene oxide aqueous solution with a concentration of 6mg / mL, and ammonium bicarbonate with a mass fraction of 0.1 was added to the solution, and after ultrasonic dispersion, it was poured on a mold plate and dried to form a graphene oxide film, and then Reduction with hydrazine hydrate reducing agent; the reduced graphene film was gradually heated up to 500°C in an inert gas atmosphere and kept for 2 hours; gradually raised to 1000°C in an inert gas atmosphere and kept for 3 hours; gradually heated to 2500°C, heat preservation for 4 hours, and the porous graphene film can be obtained after natural cooling. After the graphene film is pressed under high pressure, the PDMS insulating protective layer is coated on both sides to form an electric heating film, and electr...

Embodiment 2

[0035] Graphene oxide with an average size greater than 100um was formulated into a graphene oxide aqueous solution with a concentration of 30mg / mL, 5% urea was added to the solution, and after ultrasonic dispersion, it was poured on a mold plate and dried to form a graphene oxide film, and then used The hydrogen iodide reducing agent is used for reduction; the reduced graphene film is subjected to three-step heat treatment in an inert gas atmosphere according to the heat treatment methods shown in Table 1 to Table 3; the porous graphene film can be obtained after natural cooling. After the graphene film is pressed under high pressure, the PDMS insulating protective layer is coated on both sides to form an electric heating film, and electrodes are respectively fixed on both ends of the electric heating film, and the electrodes are connected to the graphene electric heating film. The pressure of the pressing process is 200MP, and the time is 300h.

[0036] Table 1: The heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com