Environment-friendly efficient dust suction device for textile spinning

A vacuuming device and high-efficiency technology, applied in the field of textile equipment, can solve problems such as worker hazards, environmental pollution, production equipment hazards, etc., and achieve the effects of protecting physical and mental health, ensuring safety, and improving air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

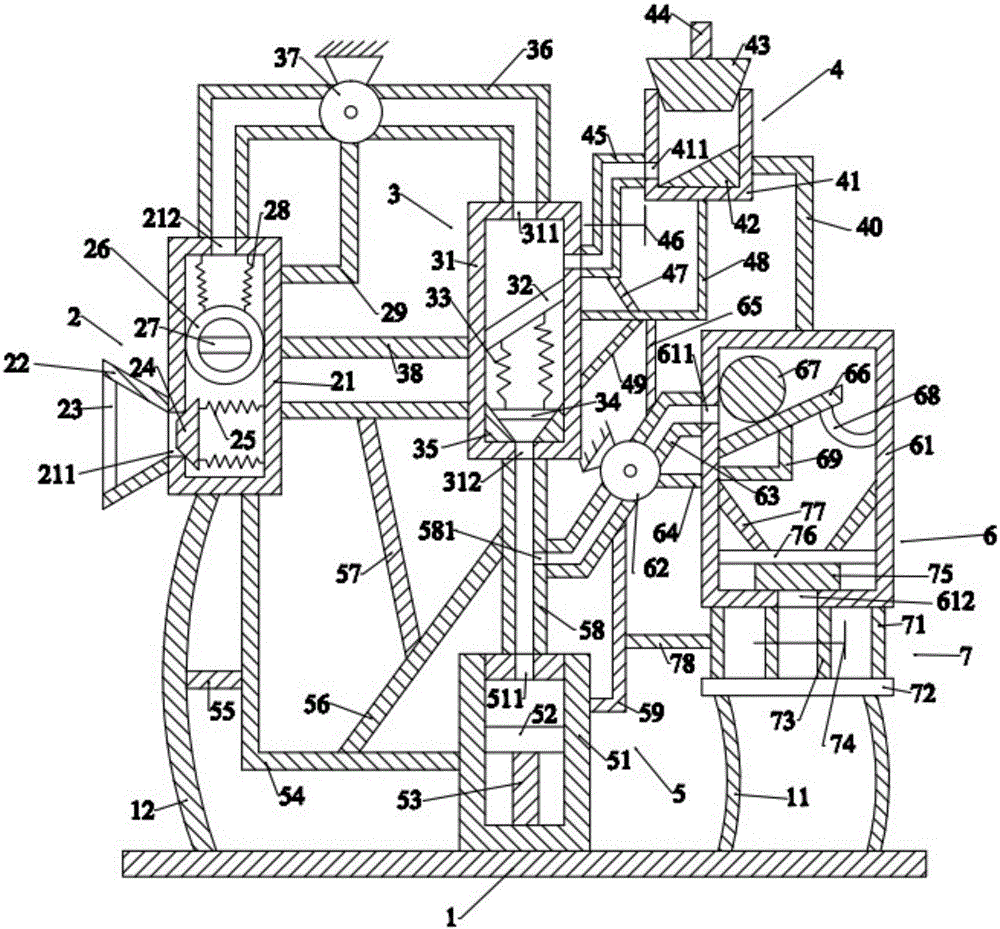

[0019] Such as figure 1 As shown, the environmental protection and high-efficiency textile dust collection device of the present invention includes a base plate 1, a first filter device 2 located above the base plate 1, a second filter device 3 located on the right side of the first filter device 2, and a second filter device 3 located on the right side of the first filter device 2. The water storage device 4 on the right side of the second filtering device 3, the collecting device 5 located below the second filtering device 3, the third filtering device 6 located on the right side of the collecting device 5, and the third filtering device 6 located on the right side of the collecting device 5 Discharge device 7 below.

[0020] Such as figure 1 As shown, the base plate 1 is a cuboid, and the base plate 1 is placed horizontally. The base plate 1 is provided with a first bending rod 11 above it and a second bending rod 12 on the left side of the first bending rod 11. . There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com