Device used for tin soldering flue gas purification

A flue gas purification and equipment technology, applied in gas treatment, use of liquid separation agent, chemical instruments and methods, etc., can solve the problems of poor air permeability of the filter, discount of adsorption effect, and influence on air quality, etc. Small resistance, high purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

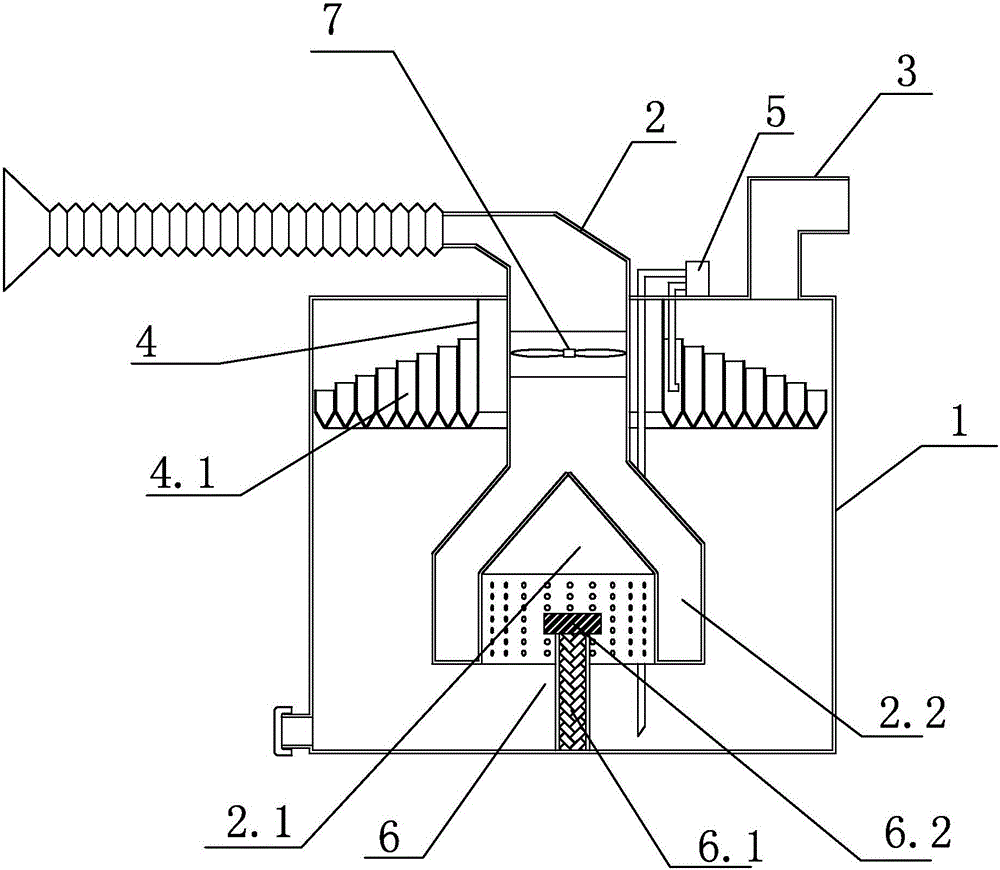

[0021] like Figure 1-4 As shown, a device for purifying solder fume includes a purification box 1, an air intake pipe 2 extending through the top plate of the purification box 1 into its interior, and an exhaust pipe 3 communicating with the purification box 1; The outer wall of the air inlet pipe 2 is sealed and connected with the top plate of the purification box 1; the end surface of the outlet end of the air inlet pipe 2 is concaved into a cavity 2.1, and the outer wall of the air inlet pipe 2 surrounds the cavity of the concave cavity 2.1 The wall forms a cavity 2.2; the cavity wall of the concave cavity 2.1 is provided with a number of exhaust holes; the top plate of the purification box 1 is provided with a liquid distributor 4 and is used to pump the liquid at the bottom of the purification box 1 into The water pump 5 of the liquid distributor 4; the bottom of the liquid distributor 4 is provided with a number of drain holes distributed along the circumference of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com