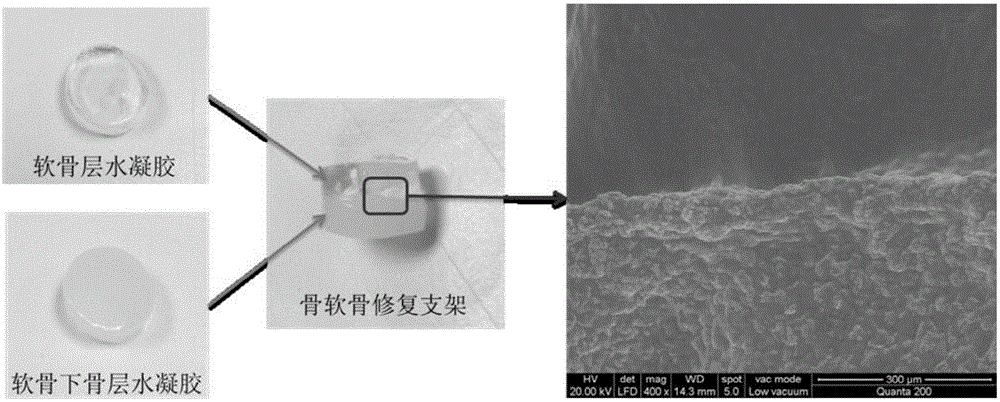

Bi-phase bone cartilage repairing support and preparing method thereof

A technique for osteochondral and preparation steps, which is applied in the field of biphasic osteochondral repair scaffolds and its preparation, can solve the problems of complex preparation methods and poor biocompatibility, and achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 1g of chitosan was added to 50ml of 3% (v / v) acrylic acid solution, stirred and reacted at 50°C for 3d, the reaction solution was dialyzed for 3d with a dialysis bag with MWCO of 8000-14000, and then freeze-dried to obtain carboxyethyl shell glycans;

[0027] (2) Dissolve 1g sodium hyaluronate in 100ml deionized water, add 0.535gNaIO 4 , react in the dark at room temperature for 3 hours, add 1.5ml of ethylene glycol to terminate the reaction for 1 hour, dialyze the reaction solution with a dialysis bag with a MWCO of 3500 for 3 days, and freeze-dry to obtain oxidized hyaluronic acid;

[0028] (3) Dissolve carboxyethyl chitosan and oxidized hyaluronic acid in PBS respectively to make a 2% g / mL solution. After fully dissolving, pour the two solutions into a cylindrical mold in equal volume and shake in a vortex. Mix evenly in the container to obtain a cylindrical cartilage layer hydrogel;

[0029] (4) Dissolve carboxyethyl chitosan and oxidized hyaluronic acid in PB...

Embodiment 2

[0033] (1) 1g of chitosan was added to 50ml of 3% (v / v) acrylic acid solution, stirred and reacted at 50°C for 3d, the reaction solution was dialyzed for 3d with a dialysis bag with MWCO of 8000-14000, and then freeze-dried to obtain carboxyethyl shell glycans;

[0034] (2) Dissolve 1g sodium hyaluronate in 100ml deionized water, add 0.535gNaIO 4 , react in the dark at room temperature for 3 hours, add 1.5ml of ethylene glycol to terminate the reaction for 1 hour, dialyze the reaction solution with a dialysis bag with a MWCO of 3500 for 3 days, and freeze-dry to obtain oxidized hyaluronic acid;

[0035] (3) Carboxyethyl chitosan and oxidized hyaluronic acid were dissolved in PBS respectively to form 3% and 5% g / mL solutions. After fully dissolving, the two solutions were poured into cylindrical moulds, Mix evenly in a vortex shaker to obtain a cylindrical cartilage layer hydrogel;

[0036] (4) Dissolve carboxyethyl chitosan and oxidized hyaluronic acid in PBS respectively to...

Embodiment 3

[0038] (1) 1g of chitosan was added to 50ml of 3% (v / v) acrylic acid solution, stirred and reacted at 50°C for 3d, the reaction solution was dialyzed for 3d with a dialysis bag with MWCO of 8000-14000, and then freeze-dried to obtain carboxyethyl shell glycans;

[0039] (2) Dissolve 1g sodium hyaluronate in 100ml deionized water, add 0.535gNaIO 4 , react in the dark at room temperature for 3 hours, add 1.5ml of ethylene glycol to terminate the reaction for 1 hour, dialyze the reaction solution with a dialysis bag with a MWCO of 3500 for 3 days, and freeze-dry to obtain oxidized hyaluronic acid;

[0040] (3) Dissolve the sterilized carboxyethyl chitosan and oxidized hyaluronic acid in sterile PBS respectively to prepare 3% and 5% g / mL solutions. After fully dissolving, the mouse bone marrow Stem cells (ATCC, CRL-2623) were added to the carboxyethyl chitosan solution, the two solutions were poured into a cylindrical mold in equal volume, and mixed evenly in a vortex shaker to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com