Low-temperature fermentation feed raw material and application of same in preparation of mixed feed for pig

A feed raw material, low-temperature fermentation technology, applied in applications, animal feed, animal feed, etc., can solve the problems of increased production costs, high fermentation temperature, high cost, etc., achieve low dry matter loss rate, low fermentation temperature, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

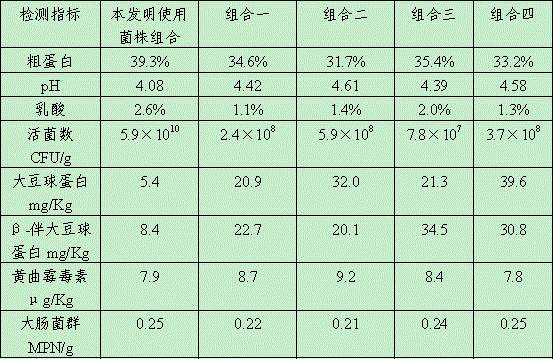

Examples

Embodiment 1

[0030] A method for producing low-temperature fermented feed raw materials suitable for use in winter in Northeast China. This method does not require additional heating equipment and can be used to produce fermented feed raw materials in winter in Northeast China or in other low-temperature regions of my country. The method includes the following steps:

[0031] (1) Grind the soybean meal, corn and rice bran meal to be fermented into 0.5-1.5mm powder, and mix them in a ratio of 50%:20%:30%. Mix the seed solutions of Bacillus pumilus CGMCCNo.4756, Saccharomyces cerevisiae CGMCCNo.8447, and Lactobacillus acidophilus CGMCCNo.5093 according to the ratio of viable bacteria 2:1:1 to make fermented seeds;

[0032] (2) Mix the fermented seeds and water into a fermented liquid, and mix the soybean meal, corn and rice bran meal powder mixture with the fermented liquid at a ratio of 1:0.8;

[0033] (3) Pile the inoculated and mixed raw materials into a raw material fermentation pile. Th...

Embodiment 2

[0039] A method for producing low-temperature fermented feed materials suitable for Northeast China, comprising the following steps:

[0040] (1) Grind the soybean meal, corn, rice bran meal and rapeseed meal to be fermented into 0.5-1.5mm powder, and mix in the ratio of 20%:50%:20%:10%. Mix the seed solutions of Bacillus pumilus CGMCCNo.4756, Saccharomyces cerevisiae CGMCCNo.8447, and Lactobacillus acidophilus CGMCCNo.5093 according to the number of viable bacteria 2:1:1 to make fermented seeds;

[0041] (2) Mix the fermented seeds and water into a fermented liquid, and mix the mixture of soybean meal, corn and rice bran meal powder with the fermented liquid at a ratio of 1:0.8 by mass to volume;

[0042] (3) Pile the inoculated and mixed raw materials into a raw material fermentation pile. The bottom area of the fermentation pile is 3 square meters and the height is 2 meters. The raw material fermentation pile is sealed with plastic cloth.

[0043] (4) Ferment at 15°C for...

Embodiment 3

[0048] A method for producing low-temperature fermented feed materials suitable for Northeast China, comprising the following steps:

[0049] (1) Crush soybean meal, corn, rice bran meal, rapeseed meal powder and DDGS into 0.5-1.5mm powder, and use it as raw material for piglet batches, according to 45%: 20%: 20%: 10%: 5% Mix the raw materials for growing and fattening pigs in a ratio of 20%: 45%: 20%: 10%: 5%. Mix the seed solutions of Bacillus pumilus CGMCCNo.4756, Saccharomyces cerevisiae CGMCCNo.8447, and Lactobacillus acidophilus CGMCCNo.5093 at 2:1:1 to make fermented seeds;

[0050] (2) Mix the fermented seeds and water into a fermentation liquid, and mix the mixture of soybean meal, corn, rice bran meal, rapeseed meal and DDGS powder with the fermentation liquid at a ratio of 1:0.8;

[0051] (3) Pile the inoculated and mixed raw materials into a raw material fermentation pile. The bottom area of the fermentation pile is 4 square meters and the height is 2 meters. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com