Method and apparatus for maintaining prefabricated dentures

A technology of dentures and jaws, used in dentures, dentistry, filling teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

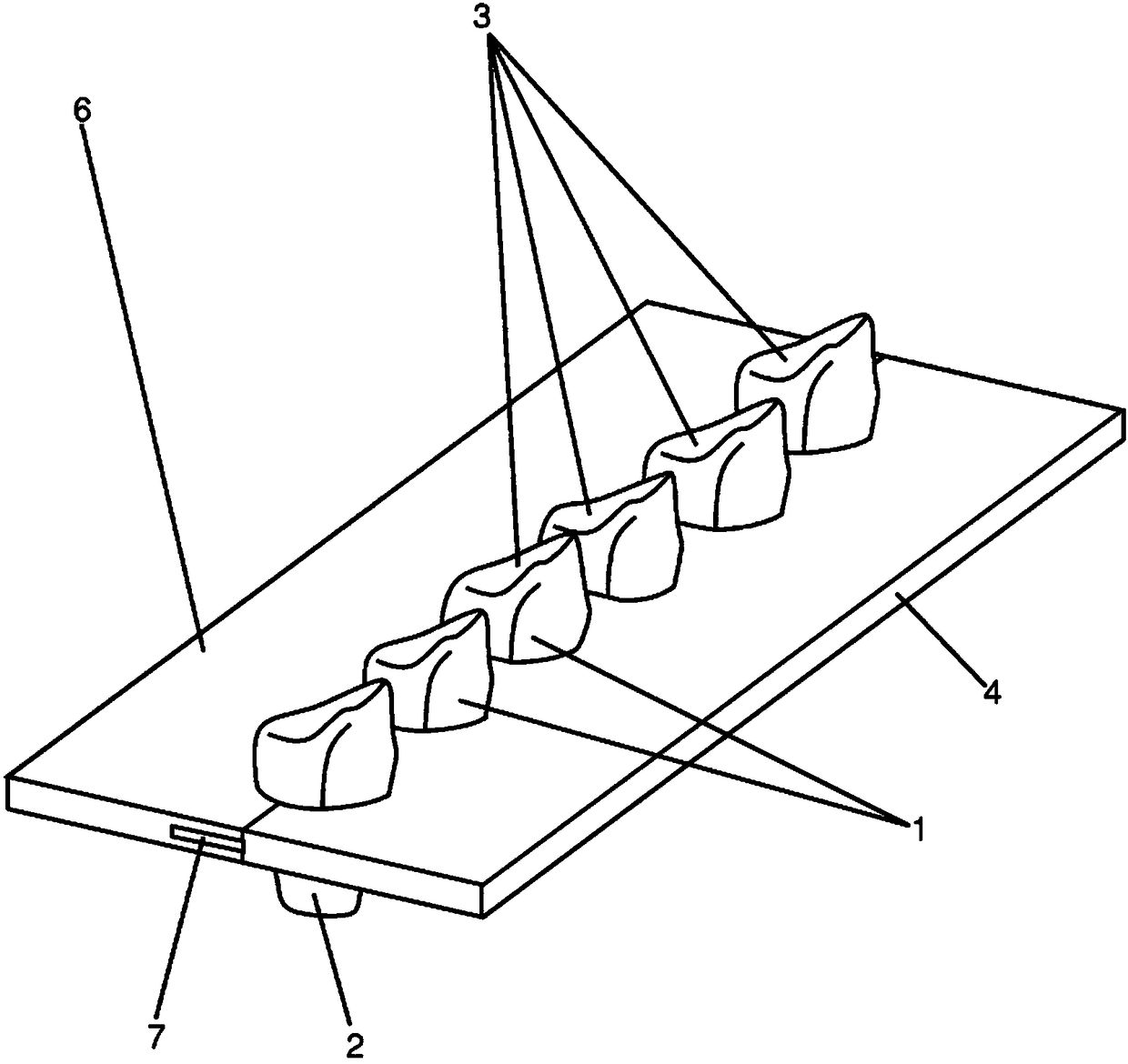

[0075] figure 1 A schematic perspective side view of the device according to the invention is shown. A prosthetic tooth 1 having a root end 2 and a coronal end 3 is clamped in the device. The device comprises two jaws 4, 6 made of dimensionally stable plastic, between which the denture 1 is clamped. The dashed lines indicate that the jaws 4 , 6 are lowered towards the denture 1 . The advantage of such a shape is that the raised frame formed by the closed jaws 4, 6 provides greater stability of the entire device, while allowing as large a part of the denture 1 as possible or the root side 2 and the coronal side 3 of the denture 1 respectively Available for machining access. The solid central line between the jaws 4 , 6 indicates the contact surface between the closed jaws 4 , 6 .

[0076] The denture 1 is initially held with a carrier (not shown). The carrier holds the denture 1 on the root side 2 or on the coronal side 3 . The central area between the heel side and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com