Tooth pressing plate for compacting stator and rotor core of large motor

A technology of large motor and tooth pressure plate, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., which can solve the problems of large tooth expansion of motor tooth pressure plate and easy breakage of teeth. , to achieve the effect of increasing the stacking pressure, preventing the deformation of the spring, and solving the problem of excessive stress and broken teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

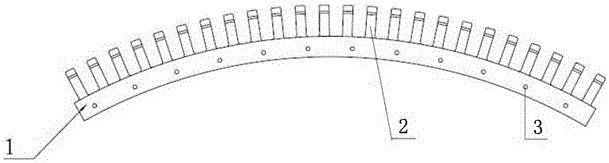

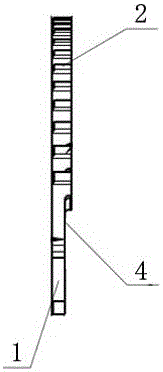

[0012] The tooth pressure plate for pressing the stator and rotor iron core of a large motor includes a tooth pressure plate body, the pressure plate body 1 of the tooth pressure plate body is provided with a side facing the opposite side of the tooth bead 2, and a lamination groove 4 penetrating with this side; The connecting hole 3 is located in the laminated groove 4 .

[0013] The tooth pressure plate is a high-strength alloy steel tooth pressure plate. The root of the lamination groove 4 is arc-shaped chamfered. The thickness of the tooth bead 2 is the sum of the thickness of the pressing plate body 1 and the deformation of the lamination groove 4 under the lamination pressure (ie the depth of the lamination groove 4), and the depth of the lamination groove 4 ranges from 1 to 6 mm.

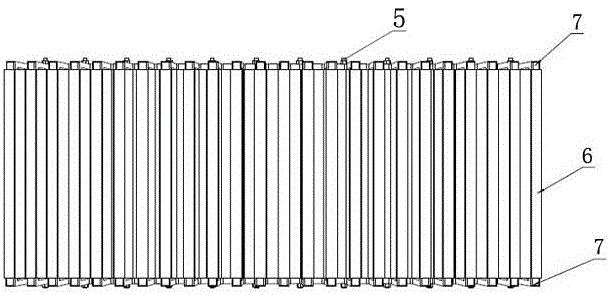

[0014] When in use, two tooth pressing plates 7 are respectively placed on both ends of the laminated silicon steel sheet 6, and the lamination groove 4 is arranged inwardly facing each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com