Winding device for battery cell winding lamination machine

A technology of a winding device and a laminating machine, which is applied to circuits, electrical components, secondary batteries, etc., can solve the problems of unstable back-and-forth movement of the lamination table, poor lamination effect, and complex structure of the whole machine. The effect of good lamination effect, improved product quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

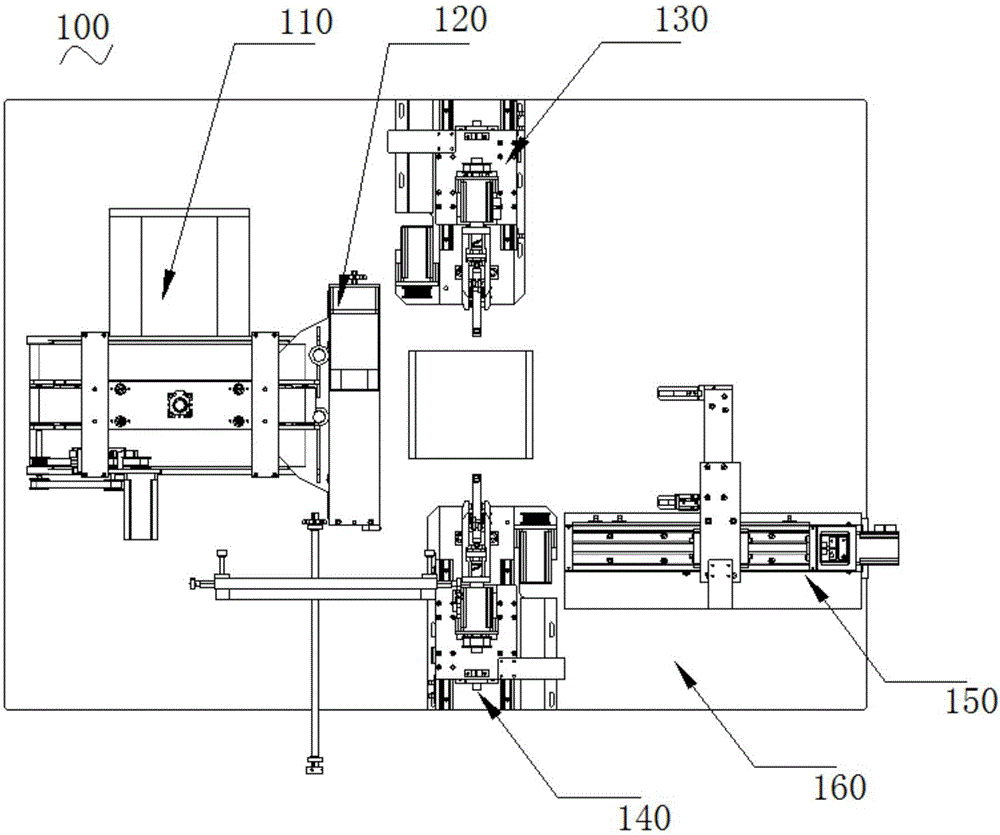

[0033] Such as figure 1 with figure 2 Shown are respectively a perspective view and a front view of the present invention.

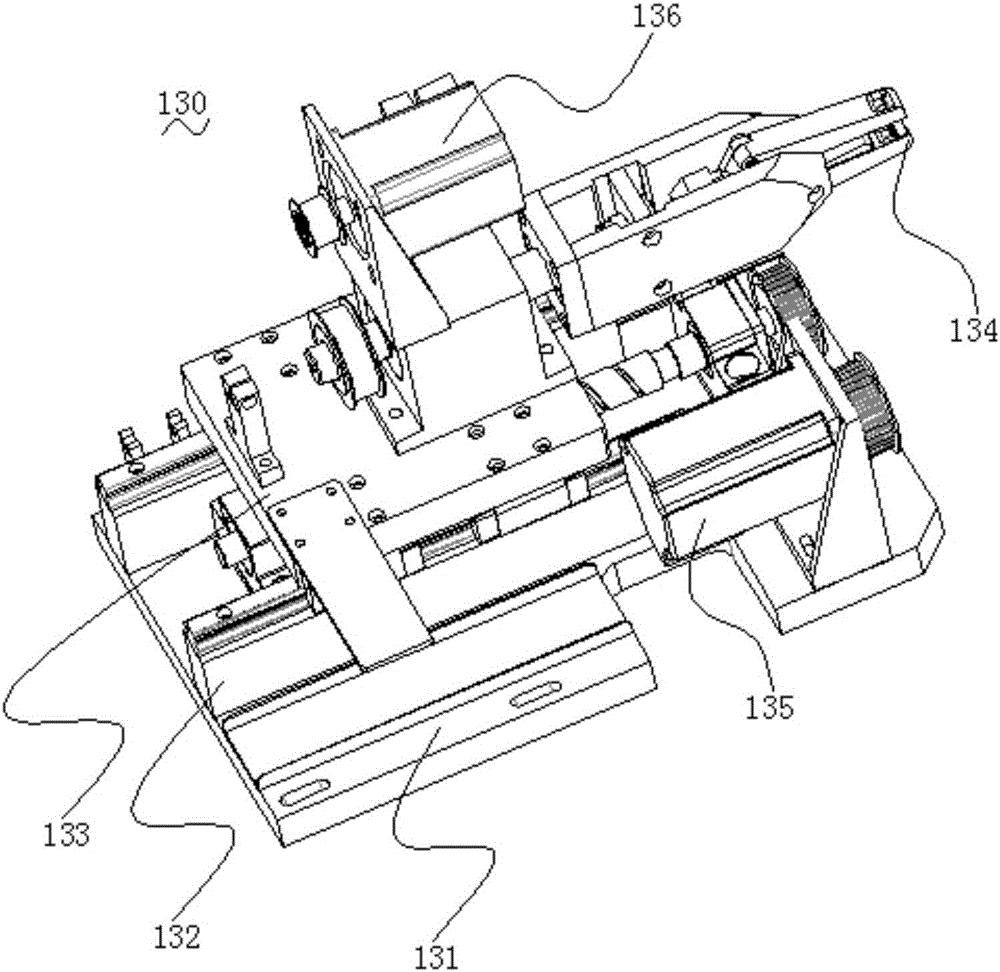

[0034]The winding device 100 for the cell winding stacker includes a sheet feeding assembly 110 for feeding the separator sheet with the positive electrode sheet and the negative electrode sheet pasted on both sides respectively, and a sheet material feeding assembly 110 for cutting the separator of the sheet The sheet cutting assembly 120, the first winding assembly 130 and the second winding assembly 140 for clamping the sheet and driving the sheet to rotate to wind the sheet into a cell, and the cell blanking assembly The cell blanking assembly 150, the first winding assembly 130 and the second winding assembly 140 are symmetrically arranged on both sides of the line connecting the sheet feeding assembly 110 and the sheet cutting assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com