A High Precision Passive Resistor Generator Compensating for the Influence of Hardware Errors

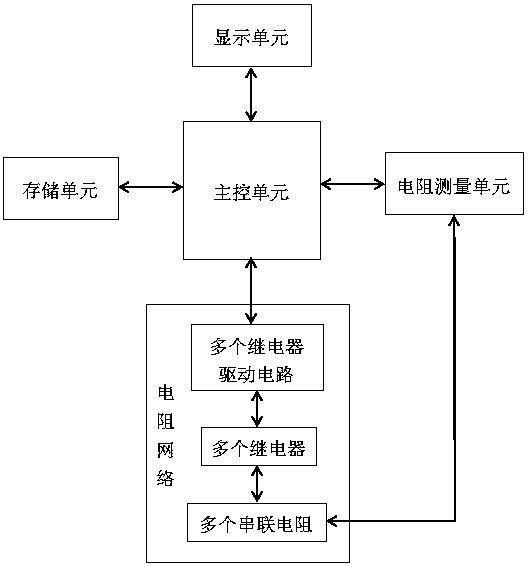

A passive resistor and generator technology, applied in the direction of resistors, adjustable resistors, other resistor networks, etc., can solve the problems of output accuracy dependence, resistance accuracy and low output accuracy, and achieve strong robustness and practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

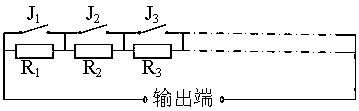

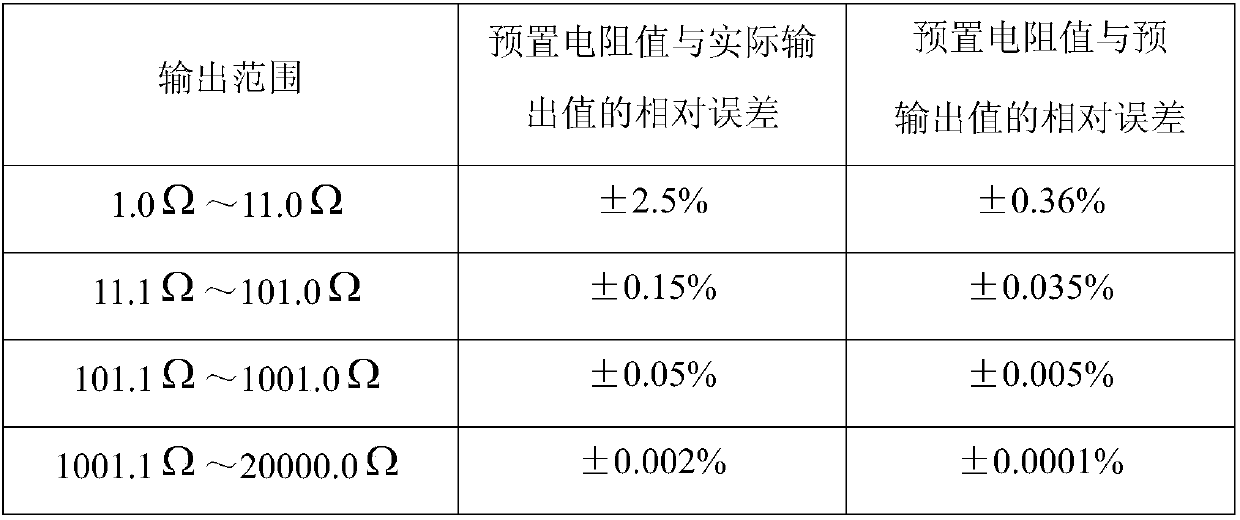

[0045] Set the output range of the passive resistance generator to 1.0Ω~20.0KΩ, the resolution is 0.1Ω, the resistance used is 0.01Ω~10KΩ, and the series resistance is selected from four bases with nominal values of 1, 2, 2 and 5 , and 25 resistors of magnitude W={0.01, 0.1, 1, 10, 100, 1000, 10000} M=1, 2, . . . , 25. The method for optimizing the resistance combination mode of the resistance network in this embodiment is:

[0046] (1) defined by The composed matrix is x 11 、x 21 ~x 74 corresponding to The nominal value corresponding to X is K ni =[K ni 1,K ni 2,K ni 3,K ni 4];

[0047] (2) by X 标 Establish the ideal output equation R 理 =∑(S1×K ni 4, S2×K ni 3, S3×K ni 2, S4×K ni 1)×W, where S1, S2, S3, and S4 are 1, 2, 2, and 5 respectively, and the resistance combination is coded according to the ideal output equation, and the resistance combination coding table shown in Table 1 is established;

[0048] (3) Obtain the matrix U=[N of all resistance...

Embodiment 2

[0053] Set the output range of the passive resistance generator to 1.0Ω~1.0MΩ, and the resolution to 0.1Ω. The series resistors use four bases with nominal values of 1, 2, 4, and 8, and the order of magnitude W={0.01, 0.1 , 1, 10, 100, 1000, 10000, 100000} 32 resistors M=1,2,...,32. The method for optimizing the resistance combination mode of the resistance network in this embodiment is:

[0054] (1) defined by The composed matrix is x 11 、x 21 ~x 84 corresponding to The nominal value corresponding to X is K ni =[K ni 1,K ni 2,K ni 3,K ni 4];

[0055] (2) by X 标Establish the ideal output equation R 理 =∑(S1×K ni 4, S2×K ni 3, S3×K ni 2, S4×K ni 1)×W, wherein S1, S2, S3, and S4 are 1, 2, 4, and 8 respectively, and the resistance combination is coded according to the ideal output equation, and the resistance combination coding table shown in Table 2 is established;

[0056] Table 2 Embodiment 2 resistance combination coding

[0057] k ni 1

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com