Overlaid insulating flexible busbar

A flexible busbar and insulating layer technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of cable wiring assembly confusion, insulation heat shrinkable sleeves, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

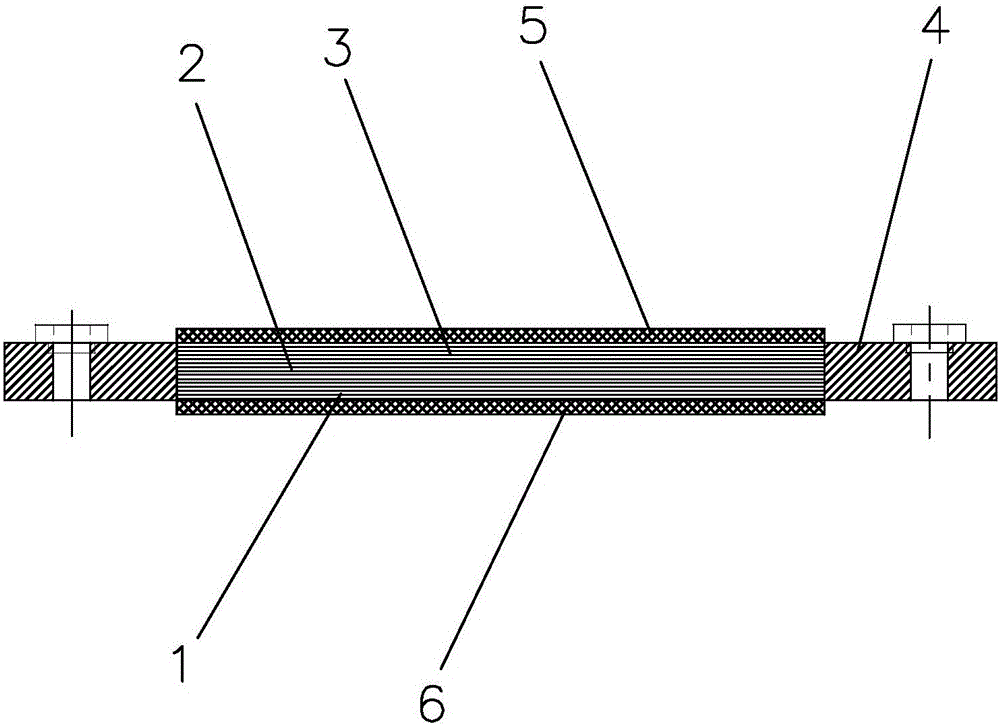

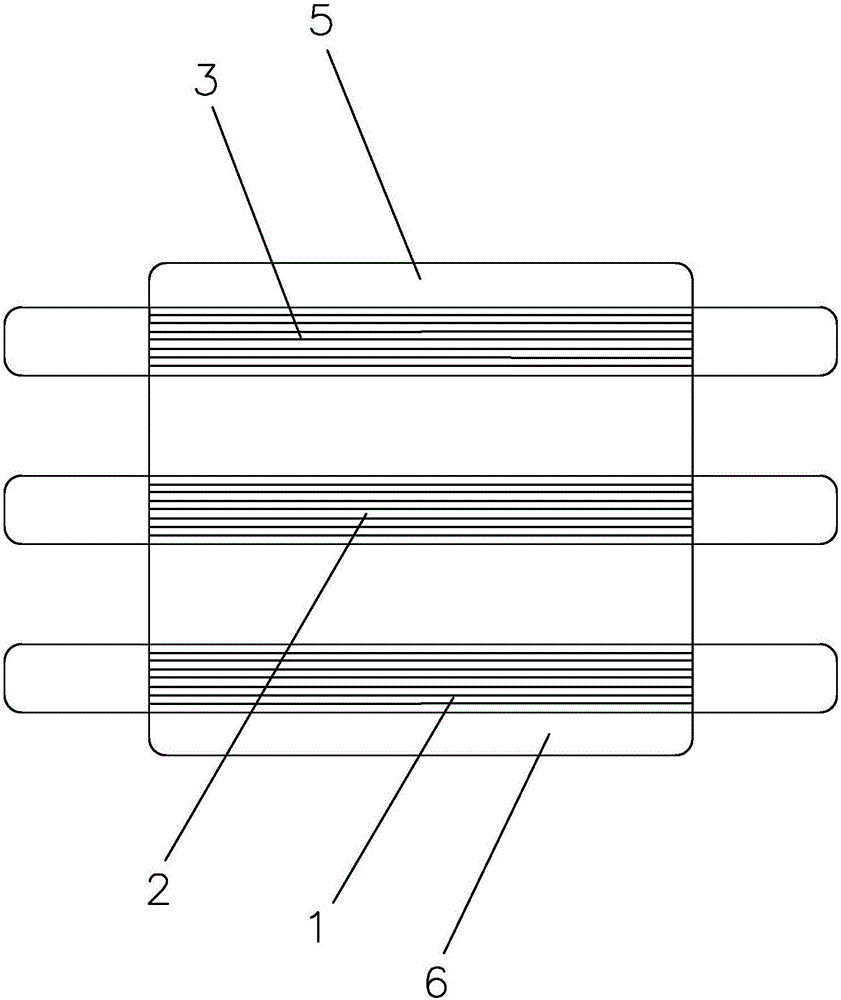

[0025] like figure 1 and figure 2 As shown, a laminated insulated flexible bus bar includes a soft connection copper bar 1, a soft connection copper bar 2 and a soft connection copper bar 3, and the soft connection copper bar 1, the soft connection copper bar 2 and the soft connection copper bar 3 There are fixed connection parts 4 at both ends, and the soft connection copper bar 1, the soft connection copper bar 2, the soft connection copper bar 3 and the fixed connection part 4 are all made of semi-hard T2 pure copper, and the fixed connection part 4 is set At both ends of the laminated insulated flexible busbar, the soft connection copper bar 1, soft connection copper bar 2 and soft connection copper bar 3 are arranged in the middle of the laminated insulated flexible busbar, and the soft connection copper bar 1, soft connection copper bar 2 and the two ends of the flexible connection copper bar 3 are respectively connected to the inner side of the fixed connection part 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com