Power equipment spot inspection machine system

A technology of electric equipment and equipment, applied in the direction of general control system, control/regulation system, computer control, etc., can solve the problems of frequent maintenance of card parts, slow maintenance process, easy corrosion, etc., to improve the standard and scientific management level, Enhanced comprehensive performance and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

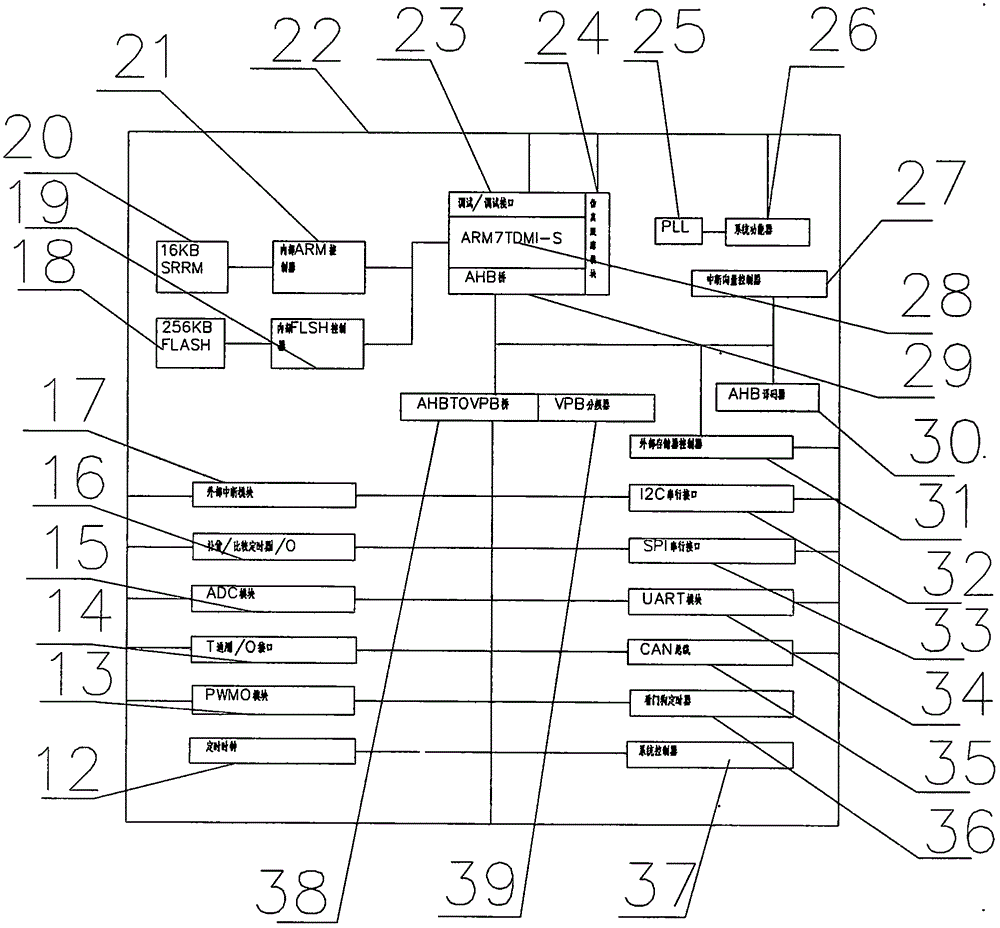

[0014] Such as figure 1 As shown, a power equipment inspection machine hardware system, which consists of: core processor 1, core processor 1 adopts LPC2214 chip, core processor 1 is divided into SRAM2, DCDC module 3, RTC module 4, thermocouple temperature Sensor module 5, SD card interface 6, LCM module 7, keyboard 8, recording module 9, USB module 10, iButton11 connection, the core processor LPC2214 model chip includes the core board, and the test / debugging interface 23, system functions are installed on the core board Module 26, simulation tracking module 24, system function module 26 is connected with PLL module 25, external interrupt module 17, capture / comparison timer O / I interface 16, ADC module 15, general I / O interface are installed on the left side of the core board 14. PWMO module 13, external memory controller 31, I2C serial interface 32,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com