Multifunctional environmental protecting and energy saving rotary kiln

An environmental protection and energy-saving rotary kiln technology, applied in the direction of furnaces, furnace types, furnace components, etc., can solve the problems of low thermal efficiency, lack of recycling of heat energy, and low degree of automation, so as to achieve increased automation, avoid heat loss, and improve The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

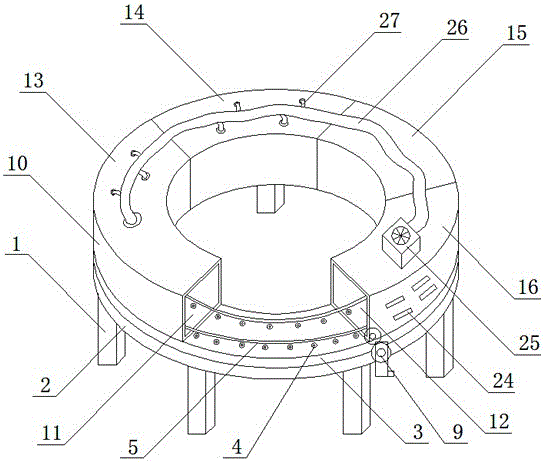

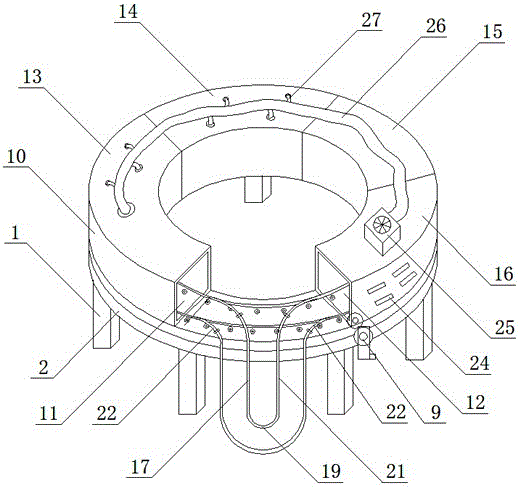

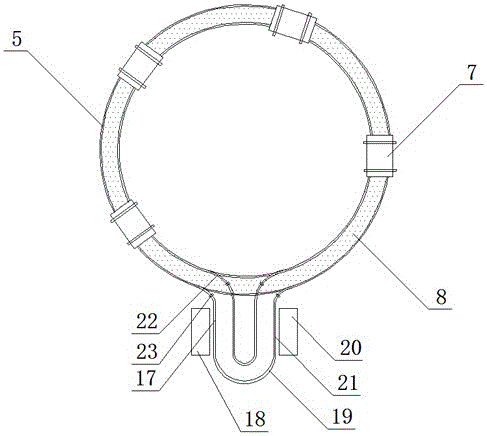

[0022] see Figure 1 to Figure 5 , a multifunctional environmental protection and energy-saving rotary kiln of the present invention, comprising a kiln body support frame 1, an annular base 2 is fixed on the upper end of the kiln body support frame 1, and it is characterized in that: the kiln body is coaxially fixed on the annular base 2 The base 3, the middle part of the annular upper surface of the kiln body base 3 is provided with an annular groove, and a plurality of limit rollers 4 are evenly installed in the annular groove, and an annular rotating track 5 is placed on the limit roller 4, and an annular rotating track 5 is rested There is a rail kiln car 7, and a plurality of installation holes are evenly opened on the side of the annular rotating track 5, and a telescopic stopper 6 corresponding to the outer end of the wheel sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com