Gob-side roadway retaining method based on roof cutting of soft roof plate

A technology of retaining roadway and roof, which is applied in the direction of earthwork drilling, underground mining, filling, etc., and can solve the problems of restricting the advancing speed of coal mining face, difficult inspection, maintenance and repair, high filling cost, etc. , to achieve the effect of improving barrier efficiency, small engineering quantity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

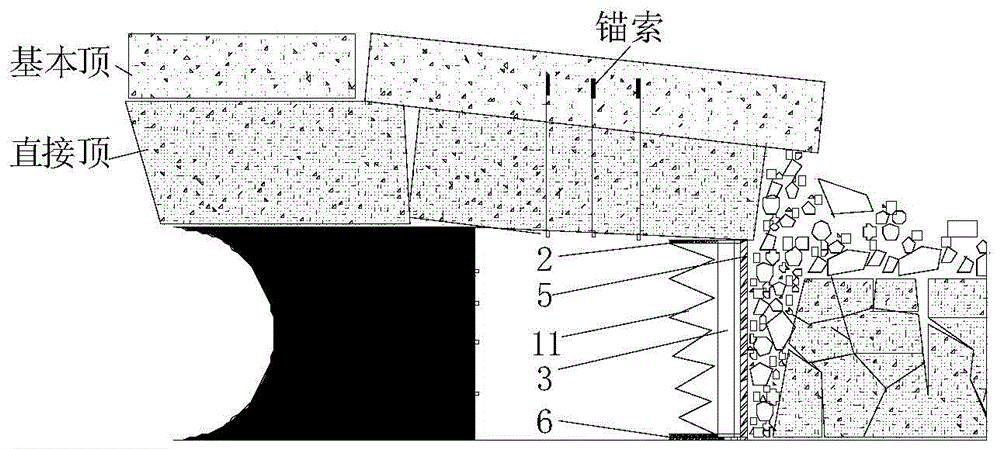

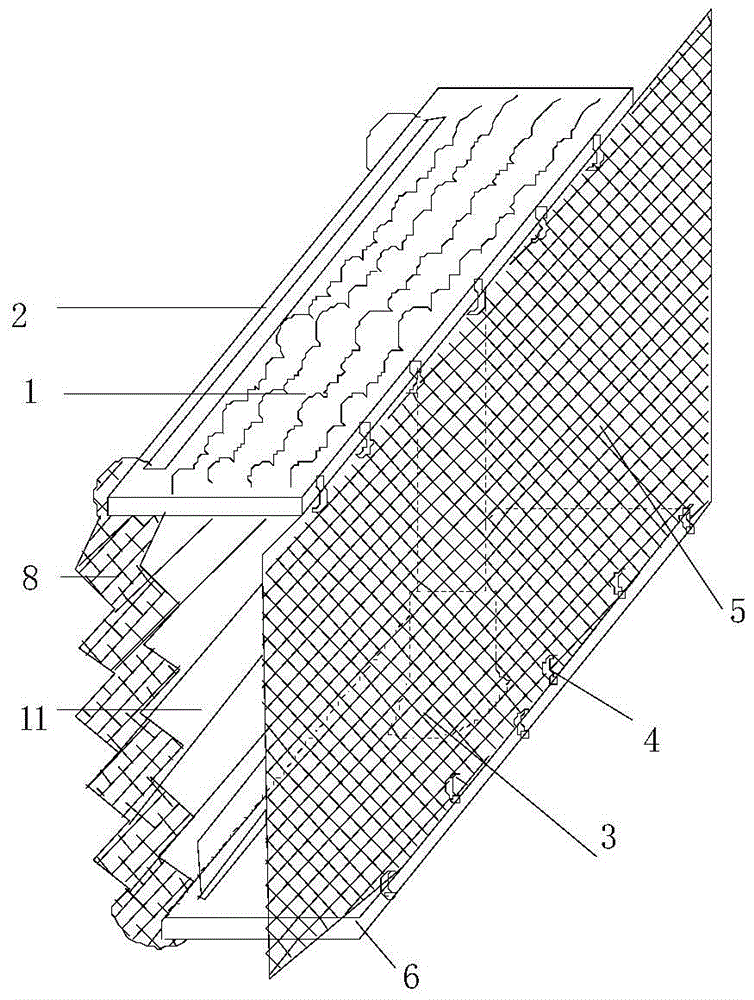

[0078] Taking the 2208 working face of a certain mine as an example, the strike length is 862m, the inclination length is 167m, and the mining coal seam is 8 上 Coal, buried depth H=610-750m, coal seam thickness 1.65-3.35m, average 2.67m, coal seam inclination 1°-5°, average 2°.

[0079] The immediate roof is made of mudstone, fine sandstone, and siltstone, belonging to Type II unstable roof, with an average thickness of 2.35m.

[0080] The basic roof belongs to the type II basic roof, mainly composed of coarse sandstone, fine sandstone, and siltstone, with an average thickness of 5.86m; the unidirectional compressive strength of the coal seam roof rock is 19.78MPa, and the unidirectional tensile strength is 0.96MPa, which is low in strength and belongs to Weak rock formations.

[0081] Retreating comprehensive mechanized coal mining is adopted.

[0082] The section of the mining roadway in the working face is rectangular, and its size is 4.6m×2.6m (clear width×clear height)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com