A Dynamic Loading and Unloading Rod Structure for Raise Drilling Rig

A kind of raise drilling rig, dynamic technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of slow unloading, inconvenient operation, etc., to achieve the effect of convenient operation and fast clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

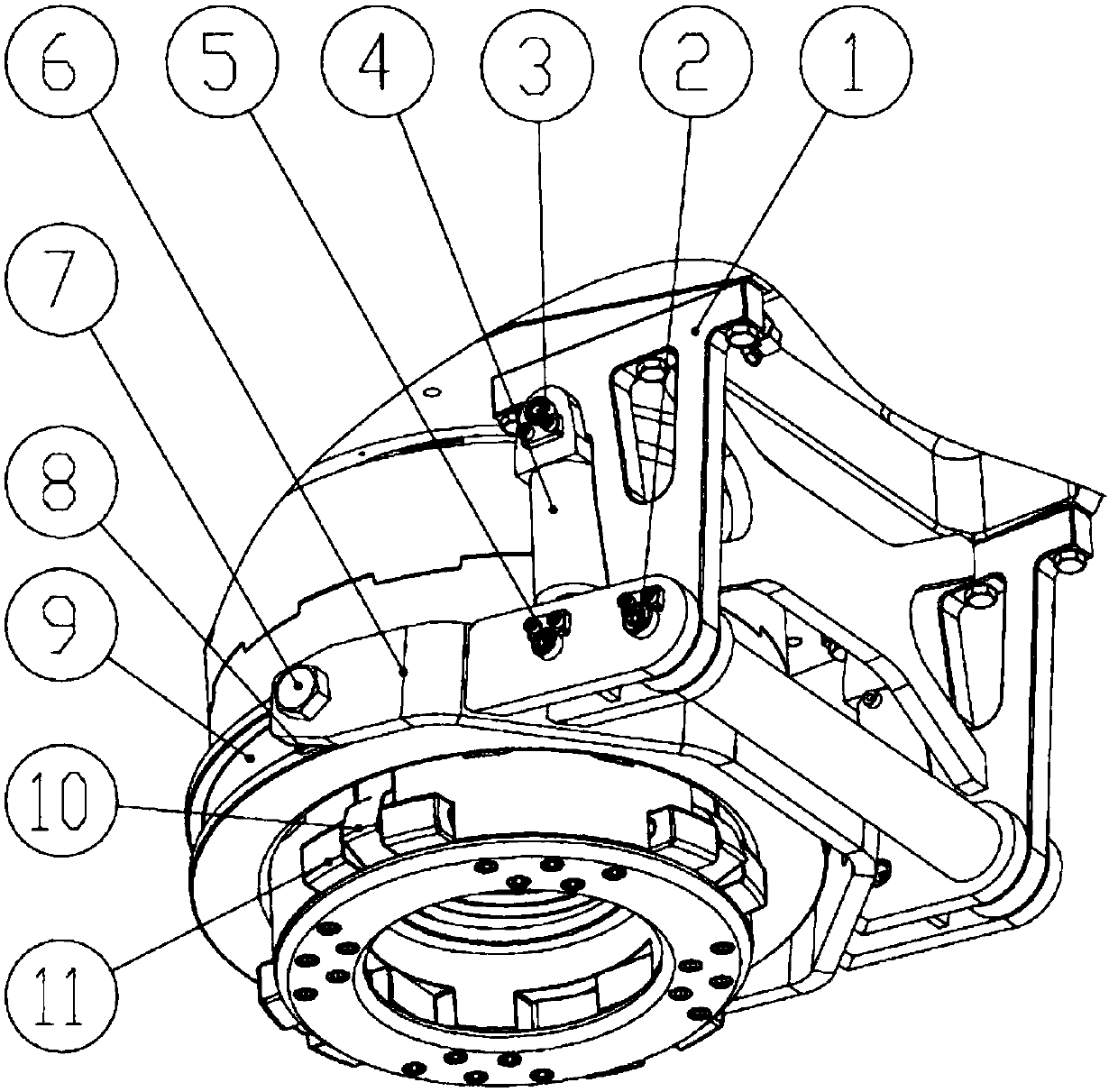

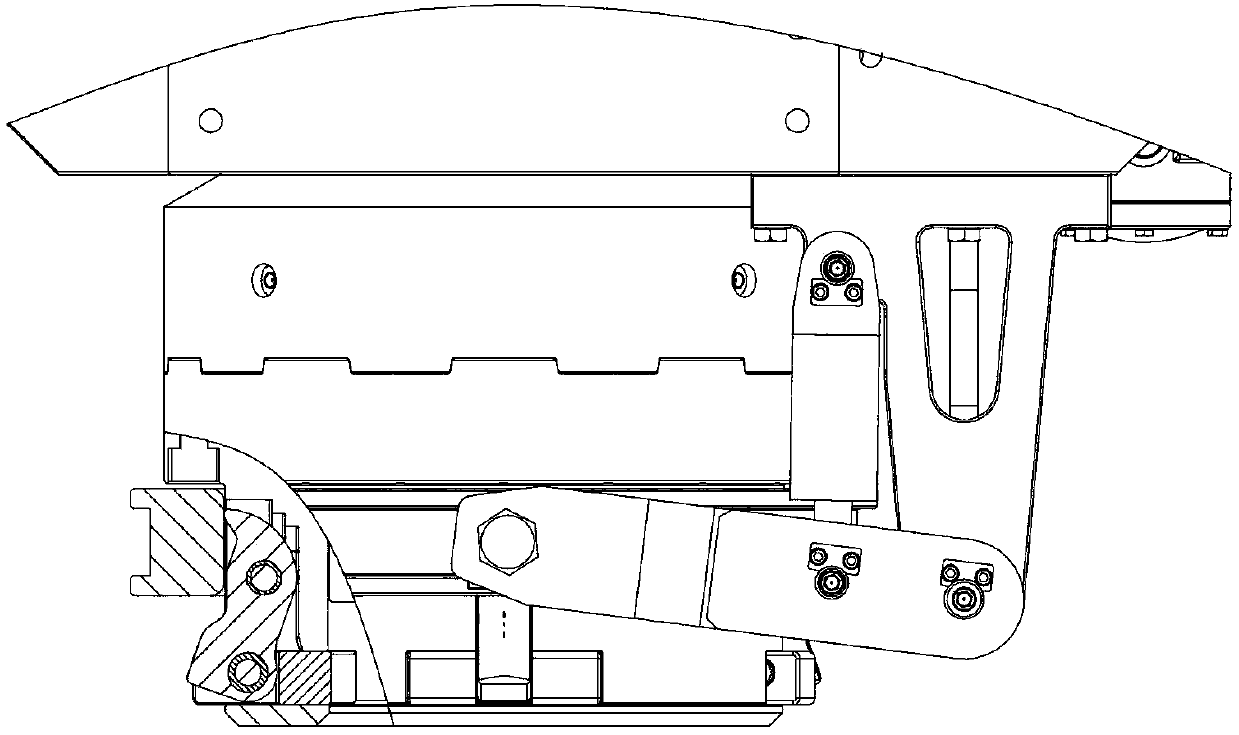

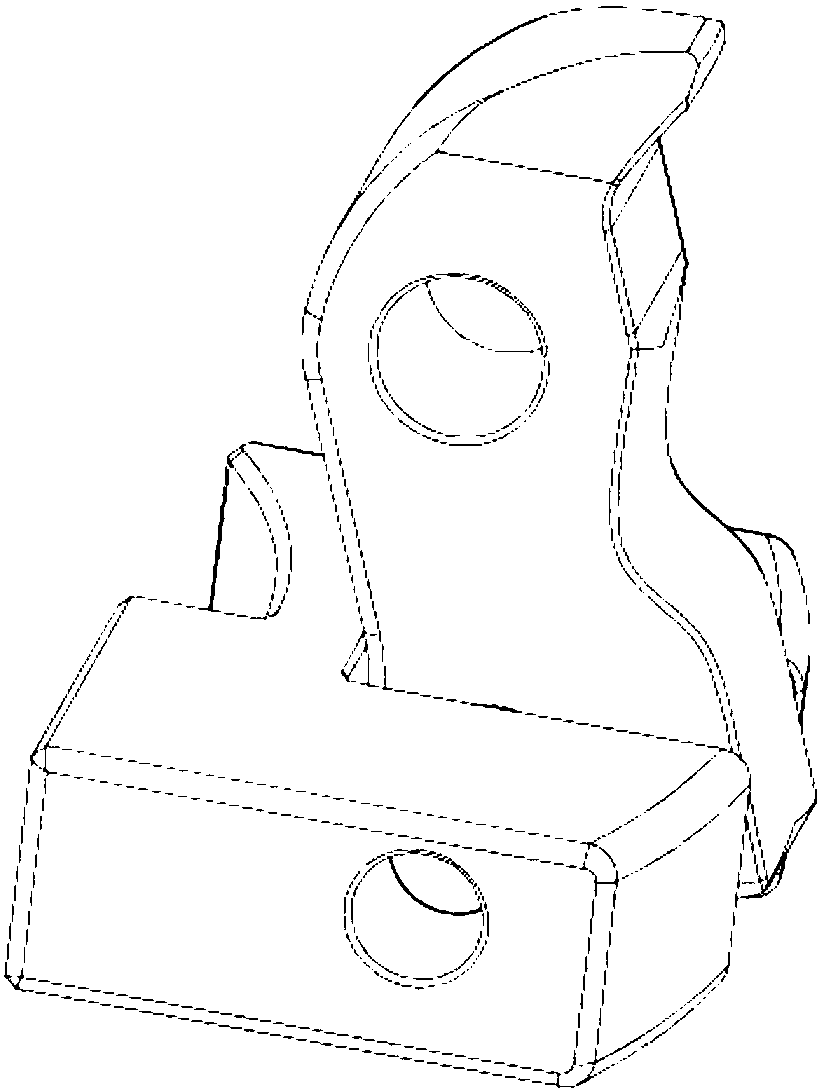

[0025] Such as figure 1 , 2 As shown, a dynamic loading and unloading rod structure for a raise drilling rig provided by the present invention includes a mounting seat 1, a lifting arm 6, an oil cylinder 4, a driving sleeve 9, a slider 8, a shifting block 10 and a clamping block 11. The mounting base 1 is connected with the slewing head box, the cylinder barrel of the oil cylinder 4 is connected with the mounting base 1 through the cylinder pin 3, and the mounting base 1 is connected with the lifting arm pin 2 6, the piston rod of the oil cylinder 4 is connected with the lifting arm 6 through the piston rod pin 5, the slider 8 is connected with the lifting arm 6 through the slider pin 7, and the slider 8 Snap into the chute of the driving sleeve 9, the shifting block 10 is connected with the head body of the rotary power head through the upper pin shaft, and the shifting block 10 is connected with the clamping block 11 through the lower pin shaft.

[0026] The oil cylinder 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com