Scaffold cantilever material platform with sheave tensioning adjustment devices

An adjustment device and scaffolding technology, which is applied in the direction of scaffolding for building structure support, building structure support, building structure support, etc., can solve problems such as wall maintenance holes, reduce wall strength, and difficulty in recycling, and achieve labor-saving and material-saving production , Obvious economic benefit, strong pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

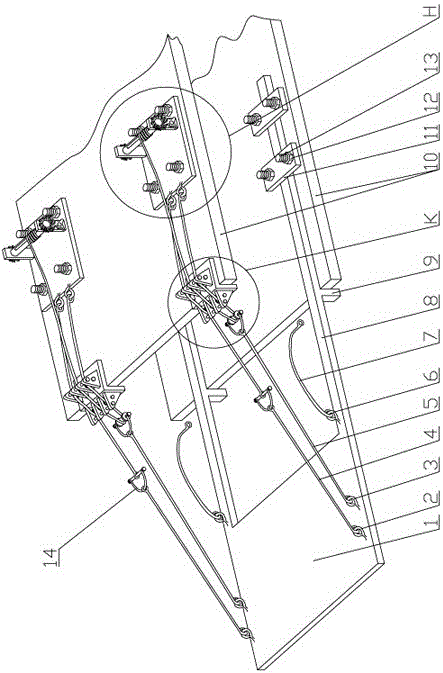

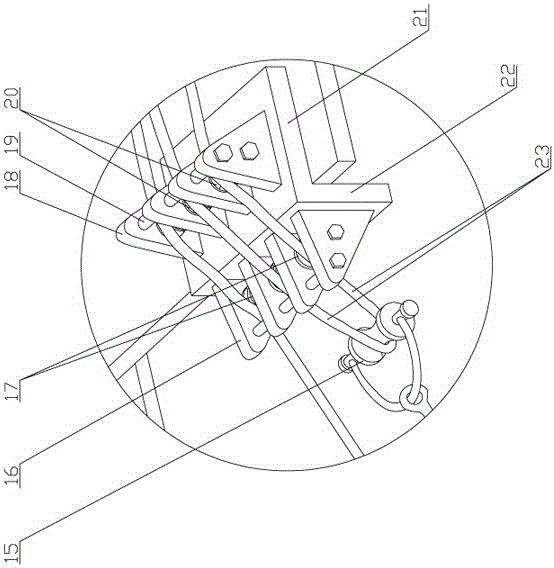

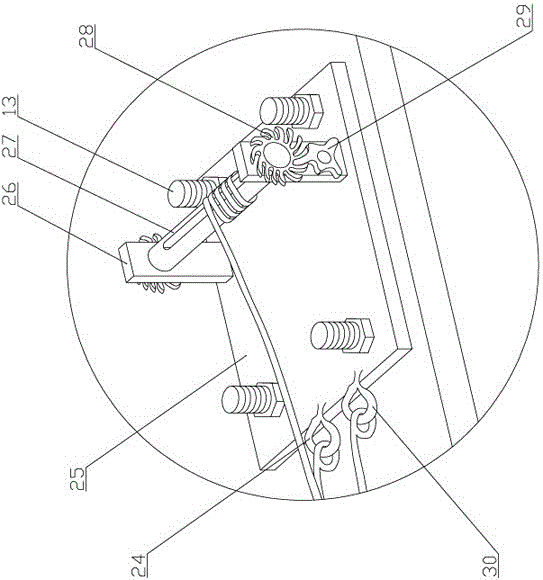

[0016] see Figure 1-Figure 3 , the present invention is a scaffold suspended material platform with a winch puller adjustment device, which has a material platform 1, and a material platform longitudinal beam 8 is provided on each side of the material platform, and each material platform longitudinal beam passes through A set of U-shaped anchor bolt fastening devices is connected to the building floor 10 slabs, and a longitudinal beam stopper 9 is provided in the middle of the bottom of each material platform longitudinal beam, and a longitudinal beam stopper 9 is provided at the symmetrical positions on both sides of the material platform. There is a group of lifting rings, and each group of lifting rings includes safety ring 2, tie ring 3 and material table lifting ring 6 in sequence, a safety wire rope 4 is connected to the safety ring, a tie wire rope 5 is connected to the tie ring, and the material table is There is a hoisting wire rope 7 connected to the hoisting ring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com