Collapsible loess wellpoint presoaking dynamic compaction replacement method

A technology of dynamic compaction replacement and pre-soaking, which is applied in the fields of soil protection, construction, and infrastructure engineering. It can solve problems such as sudden collapse of the upper soil, low bearing capacity of the foundation, and difficulty in meeting requirements, so as to shorten the construction period and improve The bearing capacity of the foundation and the effect of improving the nature of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

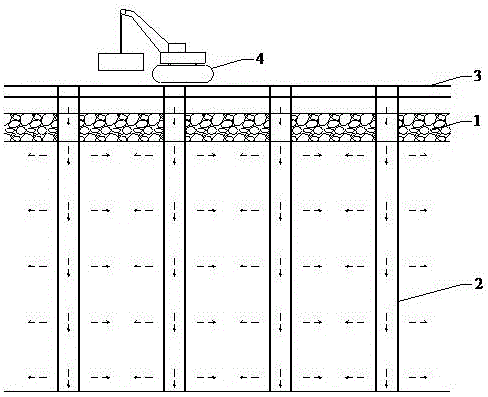

[0031] Such as Figure 1-Figure 2 As shown, the present invention provides a kind of collapsible loess well point presoaking water dynamic compaction replacement method, it is characterized in that, comprises the following steps:

[0032] Step 1, determining the treatment range and treatment depth of the foundation;

[0033] According to the geological survey data and building codes in collapsible loess areas, determine the plane treatment range and treatment depth of the collapsible loess foundation site;

[0034] Step 2, within the scope of foundation treatment, such as figure 1 As shown, the cushion material 1 is laid all over the surface; the cushion material 1 includes one or more coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com