A light-weight high-conductivity heat-resistant aluminum wire and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

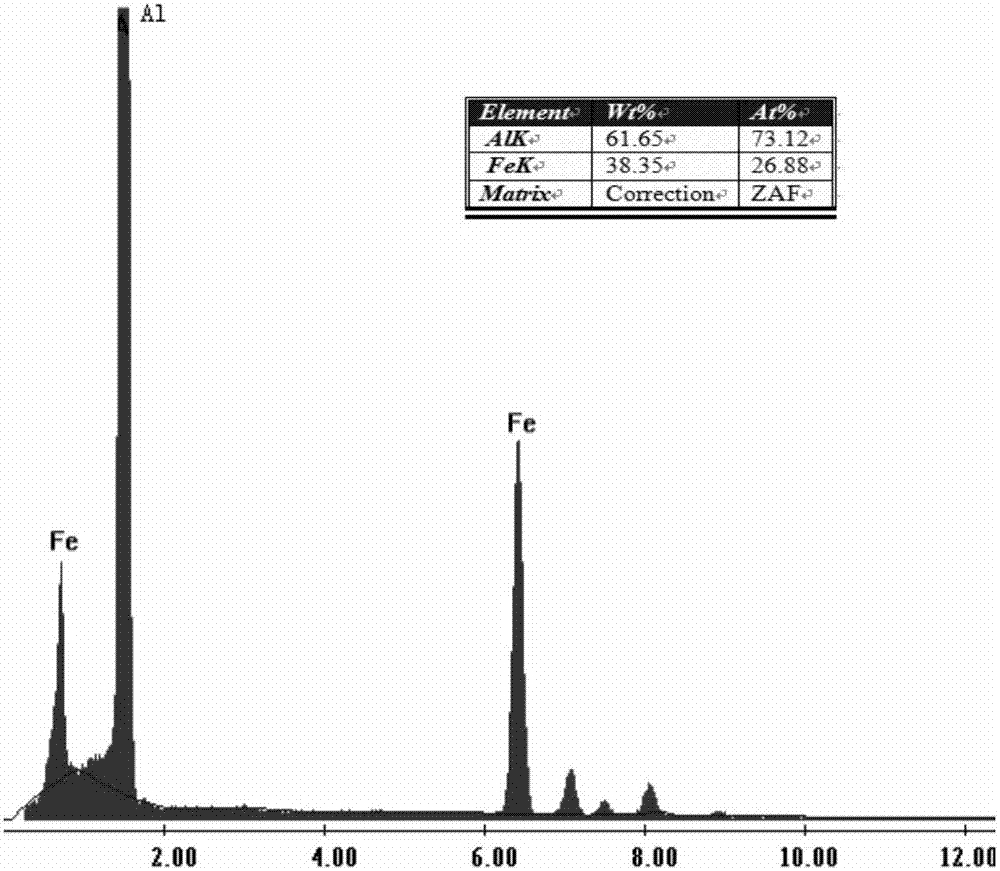

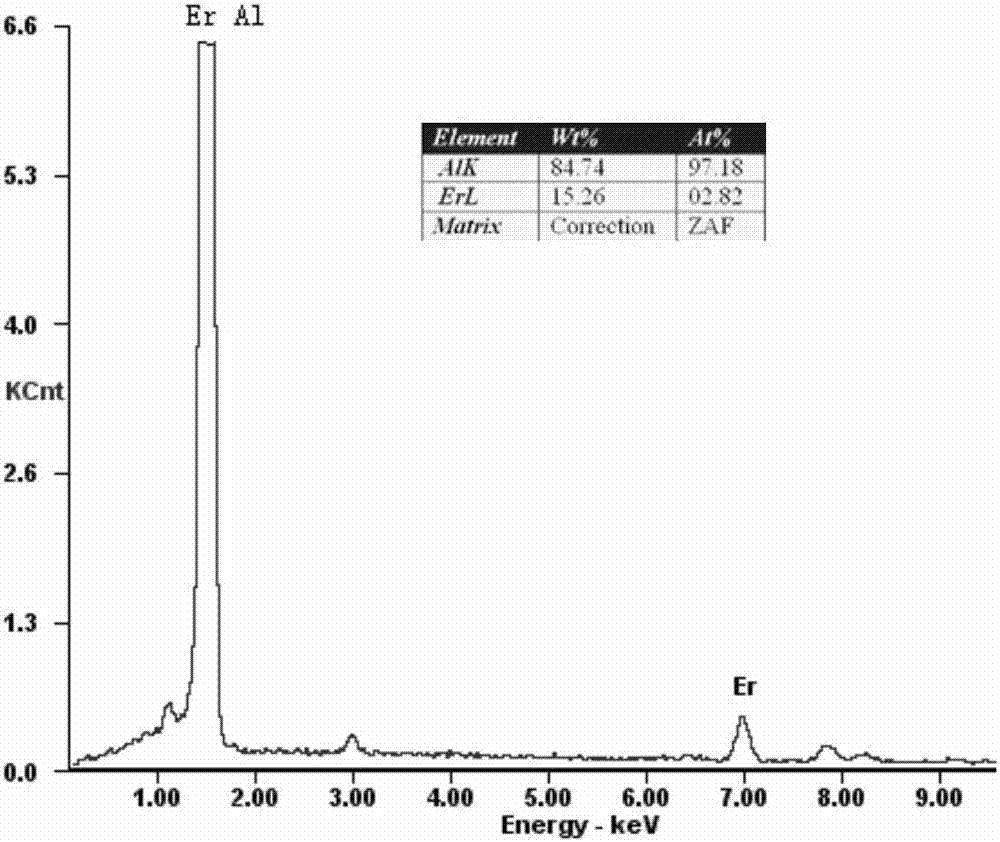

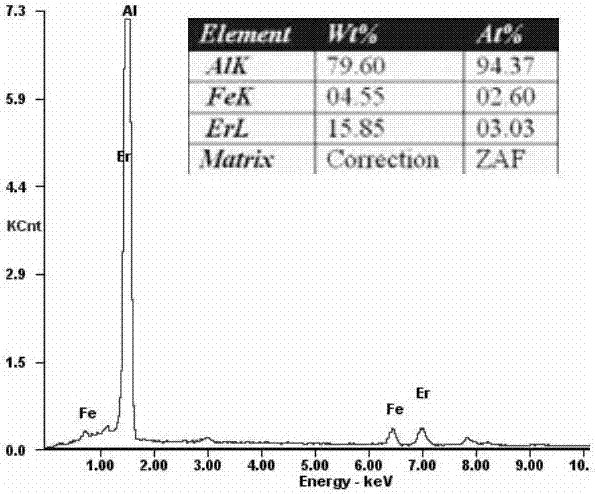

[0057] Using industrial pure aluminum ingots with a purity greater than 99.7%, Al-11.34% Zr master alloy and Al-4.7% Er master alloy as raw materials, first melt industrial pure aluminum at 760°C, then add Al-Zr and Al-Er master alloys After the intermediate alloy is completely melted and stirred evenly, the Zr, Er, and Al alloy melts are subjected to rapid component analysis before the furnace, and the alloy melts are lowered to 730°C for heat preservation. 2 times the content and the mass percentage of B in the alloy, add Al-2.5% B master alloy for refining, so that the mass percentage of each element is: B is 0.035wt.%, Zr is 0.1wt.%, Er is 0.21wt. %, the sum of Ti, V, Cr, Mn and other impurity elements is 0.001wt.%, and Al is the balance. Stirring, standing still, slag removal, and water-cooled casting are then carried out in sequence. The bad material was kept at 480°C for 10 hours and cooled in the furnace, and then hot-extruded at 420°C. The extrusion ratio was 89.7, a...

Embodiment 2

[0060]Using industrial pure aluminum ingots with a purity greater than 99.7%, Al-11.34% Zr and Al-4.7% Er master alloys as raw materials, melt industrial pure aluminum at 760°C, add Al-Zr, Al-Er master alloys, and wait for the intermediate After the alloy is completely melted and stirred, the Zr, Er, and Al alloy melts are subjected to rapid component analysis before the furnace, and the alloy melt is lowered to 730°C for heat preservation, and then the total content of impurity elements Ti and V in the alloy melt is 3.5 times And the mass percentage of B in the alloy, adding Al-2.5% B master alloy for refining, so that the mass percentage of each element is: B is 0.05wt.%, Zr is 0.1wt.%, Er is 0.21wt.%, Ti, The sum of V, Cr, Mn and other impurity elements is 0.001wt.%, and Al is the balance. Stirring, standing still, slag removal, and water-cooled casting are then carried out in sequence. The bad material was kept at 490°C for 8 hours and cooled in the furnace, and then hot-...

Embodiment 3

[0063] Using industrial pure aluminum ingots with a purity greater than 99.7%, Al-11.34% Zr master alloy and Al-4.7% Er master alloy as raw materials, after melting industrial pure aluminum at 760°C, adding Al-Zr and Al-Er master alloys, After the intermediate alloy is completely melted and stirred, the Zr, Er, and Al alloy melts are subjected to rapid component analysis in front of the furnace, and the alloy melt is lowered to 730°C for heat preservation, and then the total content of impurity elements Ti and V in the alloy melt is determined 5 times and the mass percentage of B in the alloy, after adding Al-2.5% B master alloy for refining, the mass percentage of each element is: B is 0.06wt.%, Zr is 0.2wt.%, Er is 0.4wt.%, Ti , V, Cr, Mn and other impurity elements total 0.001wt.%, Al is the balance. Stirring, standing still, slag removal, and water-cooled casting are then carried out in sequence. The billet was kept at 500°C for 1 hour and cooled in the furnace, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com