A new environmentally friendly synthetic slagging material

A technology of slagging and environmental protection, which is applied in the field of steelmaking and refining, can solve the problems of insufficient slagging capacity of the converter, failure to achieve rapid slagging, slow slagging speed, etc., and achieve considerable benefits, superior slagging performance, and less slag volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

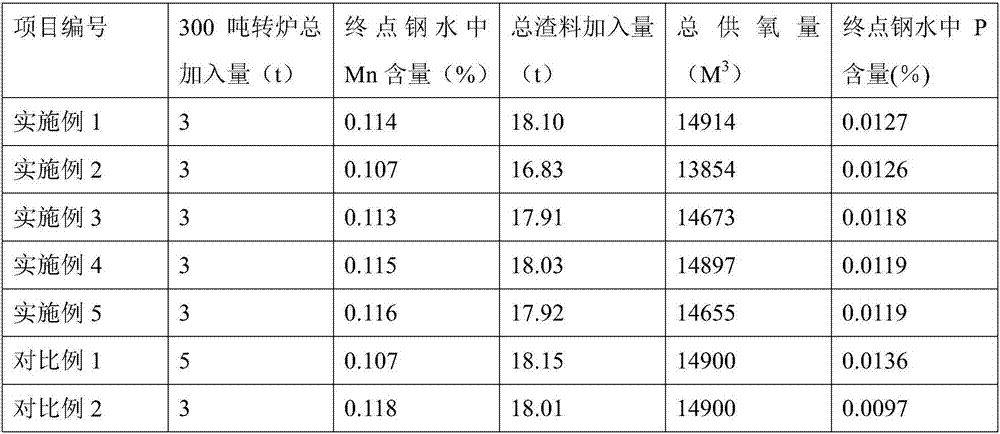

Examples

Embodiment 1

[0031] Formula: The parts by weight of raw materials are as follows: CaO: 12 parts, aluminum ash powder: 15 parts, SiO 2 : 72 parts, MnO: 2 parts, FeO: 9 parts, yttrium oxide Y 2 o 3 : 4.5 servings.

[0032] Preparation:

[0033] 1) crushing aluminum slag and ball milling into powder to obtain aluminum ash powder;

[0034] 2) Add other raw materials and mix well, that is.

Embodiment 2

[0036] Formula: The parts by weight of raw materials are as follows: CaO: 11 parts, aluminum ash powder: 5 parts, SiO 2 : 70 parts, MnO: 1 part, FeO: 8 parts, yttrium oxide Y 2 o 3 : 2 servings.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] Formula: The parts by weight of raw materials are as follows: CaO: 14 parts, aluminum ash powder: 25 parts, SiO 2 : 73 parts, MnO: 2 parts, FeO: 10 parts, yttrium oxide Y 2 o 3 : 5 servings.

[0040] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com