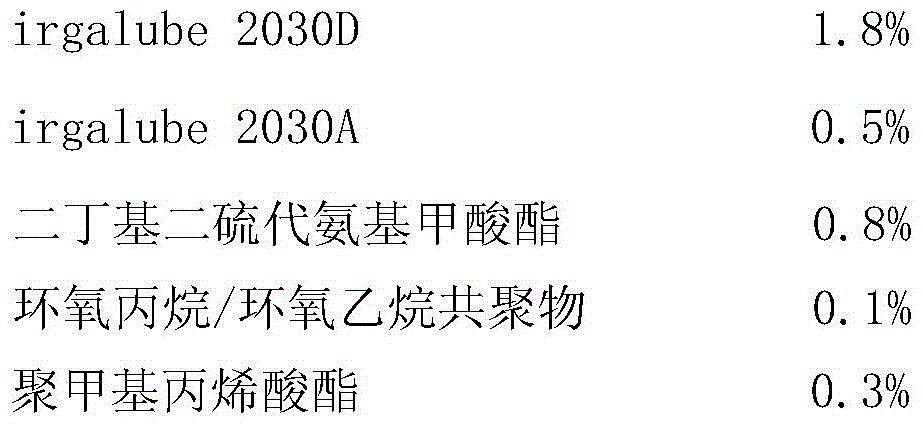

High-efficiency rolling mill oil film bearing oil composition

A high-efficiency, bearing oil technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of influence, non-standard use process of lubricating oil, etc., achieve the effect of reducing abrasion, reducing maintenance expenditure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

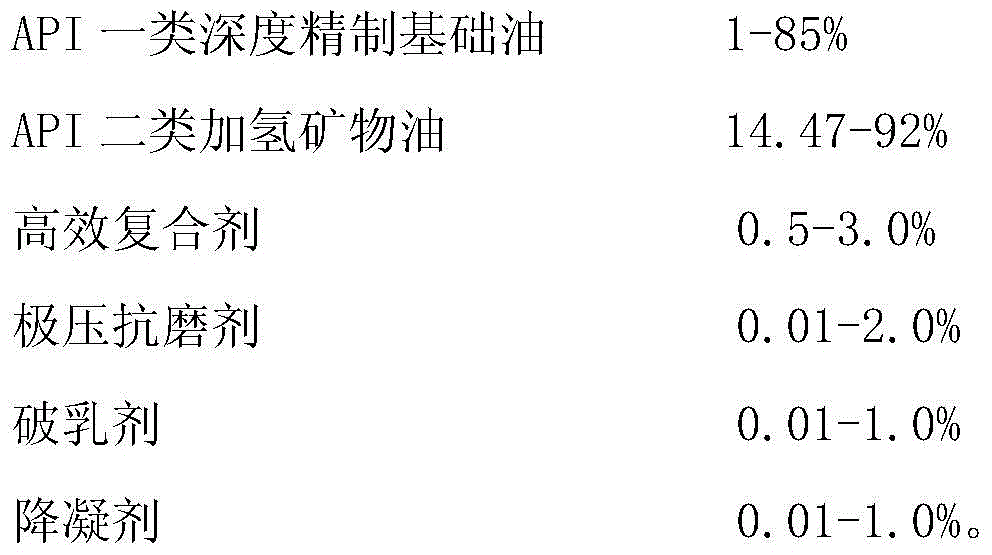

[0019] High-efficiency rolling mill oil film bearing oil composition

[0020] First configure the base oil of the high-efficiency rolling mill oil film bearing oil composition of the present invention: add GS600N76.5%, Dalian 400SN18.5%, Thailand 150BS1.5% in a blending kettle with a stirrer, and stir at 50-70°C 1-4h to prepare the base oil of the composition, then add the following substances to the base oil and stir to obtain the composition of the present invention.

[0021]

Embodiment 2

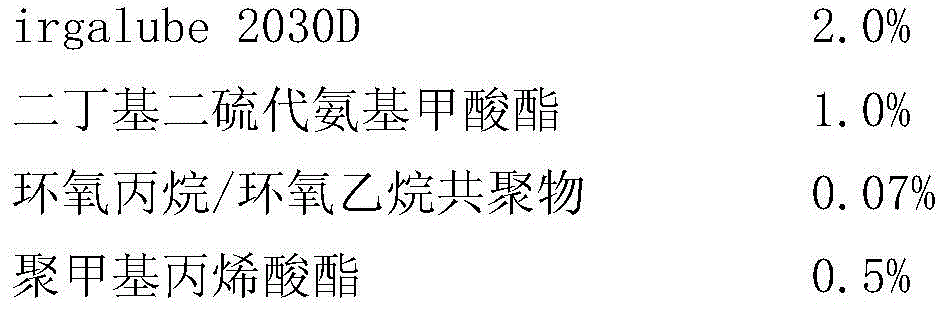

[0023] High-efficiency rolling mill oil film bearing oil composition

[0024] First configure the base oil of the high-efficiency rolling mill oil film bearing oil composition of the present invention. Add Formosa Plastics 500N89.4% and Indonesian 150BS7% to a mixing kettle with a stirrer, stir at 50-70°C for 1-4h to prepare the base oil of the composition, then add the following substances to the base oil and stir to obtain Compositions of the invention.

[0025]

Embodiment 3

[0027] High-efficiency rolling mill oil film bearing oil composition

[0028] First configure the base oil of the high-efficiency rolling mill oil film bearing oil composition of the present invention. Add 58% SK500N, 10% Indonesian 150BS, and 27.9% Russian 250SN to a mixing tank with a stirrer, stir at 50-70°C for 1-4 hours to prepare the base oil of the composition, and then add the following substances to the base oil, Stirring gives the composition of the present invention.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com