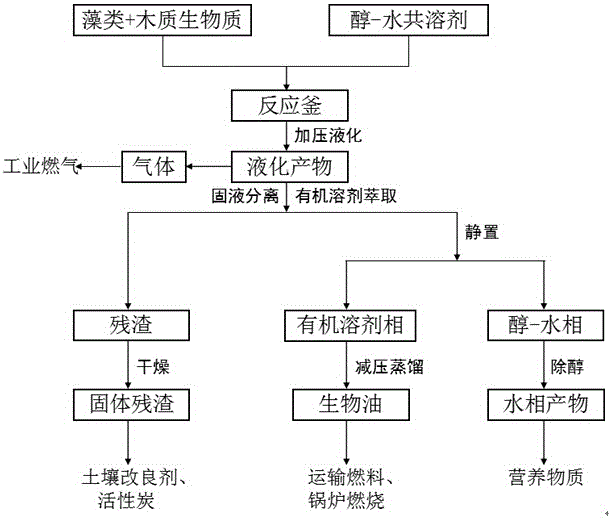

Method for preparing biological oil by co-liquefaction of algae and lignocellulosic biomass

A woody biomass and co-liquefaction technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and liquid carbon-containing fuels, can solve the problems of poor reaction conditions and harshness of bio-oil products, and achieve strong environmental adaptability and easy Separation, the effect of high photosynthetic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Crush 5g of spirulina and 5g of pine sawdust into particles with a particle size of 0.2mm to form a homogeneous mixture with a mass ratio of 1:1, and then mix it with 100ml of ethanol-water co-solvent with a volume ratio of 1:1 to fully Mix to form a slurry with a solid-to-liquid ratio of 10g:100ml, and add it to a high-temperature and high-pressure hydrothermal reactor;

[0033] (2) Seal the reaction kettle, fill it with nitrogen gas with an initial pressure of 5MPa, and set the magnetic stirring speed at 1000r / min. After heating up to a given temperature, the co-liquefaction reaction is carried out. The reaction temperature is 300°C, the pressure is 30MPa, and the reaction time is 60min;

[0034] (3) After the reaction is completed, cool the high-temperature and high-pressure hydrothermal reactor to room temperature, collect the gaseous product, and add dichloromethane to the liquefied product for extraction;

[0035] (4) Separating the extracted liquefied product...

Embodiment 2

[0039] (1) Crush 5g of chlorella and 5g of rice husk into particles with a particle size of 0.2mm to form a homogeneous mixture with a mass ratio of 1:1, and then mix with 100ml of methanol-water co-solvent with a volume ratio of 1:1 to water Fully mix to form a slurry with a solid-to-liquid ratio of 10g:100ml, and add it to a high-temperature and high-pressure hydrothermal reactor;

[0040] (2) Seal the reaction kettle, fill it with nitrogen gas with an initial pressure of 10MPa, and set the magnetic stirring speed at 1000r / min. After heating up to a given temperature, the co-liquefaction reaction is carried out. The reaction temperature is 320°C, the pressure is 30MPa, and the reaction time is 45min;

[0041] (3) After the reaction is completed, cool the high-temperature and high-pressure hydrothermal reactor to room temperature, collect the gaseous product, and add acetone to the liquefied product for extraction;

[0042] (4) Separating the extracted liquefied product into ...

Embodiment 3

[0046] (1) Crush 5g of blue-green algae and 5g of pine wood chips into particles with a particle size of 0.2mm to form a homogeneous mixture with a mass ratio of 1:1, and then fully mix with 100ml of ethanol-water co-solvent with a volume ratio of alcohol to water of 1:1 Form a slurry with a solid-to-liquid ratio of 10g:100ml, and add it to a high-temperature and high-pressure hydrothermal reactor;

[0047] (2) Seal the reaction kettle, fill it with hydrogen gas with an initial pressure of 5MPa, and magnetically stir at a speed of 1000r / min. After heating up to a given temperature, the co-liquefaction reaction is carried out. The reaction temperature is 300°C, the pressure is 30MPa, and the reaction time is 30min;

[0048] (3) After the reaction is completed, cool the high-temperature and high-pressure hydrothermal reactor to room temperature, collect the gaseous product, and add dichloromethane to the liquefied product for extraction;

[0049] (4) Separating the extracted liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com