Low-viscosity high-shear high-density oil-base drilling fluid

An oil-based drilling fluid, high-density technology, applied in the field of drilling, can solve the problems of easy high temperature thickening failure, high plastic viscosity, low shear force, etc., to achieve easy rheological properties, good temperature resistance, easy operation and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Measure 320mL of white oil in a 500mL high stirring cup, add 12.0g of emulsifier G326 and 8.0g of calcium hydroxide (accurate to 0.0lg) while stirring with a high-speed stirrer, and slowly add 80mL of CaCl after stirring for 10 minutes 2 Brine, 12.0g fluid loss reducer G328, 2.0g viscosifier G336-VIS and 6.0g shearing agent G322-MOD, total high-speed stirring for 90min, interrupt once every 20min to scrape off the slurry adhering to the cup wall, and finally add Barite to achieve the required drilling fluid density.

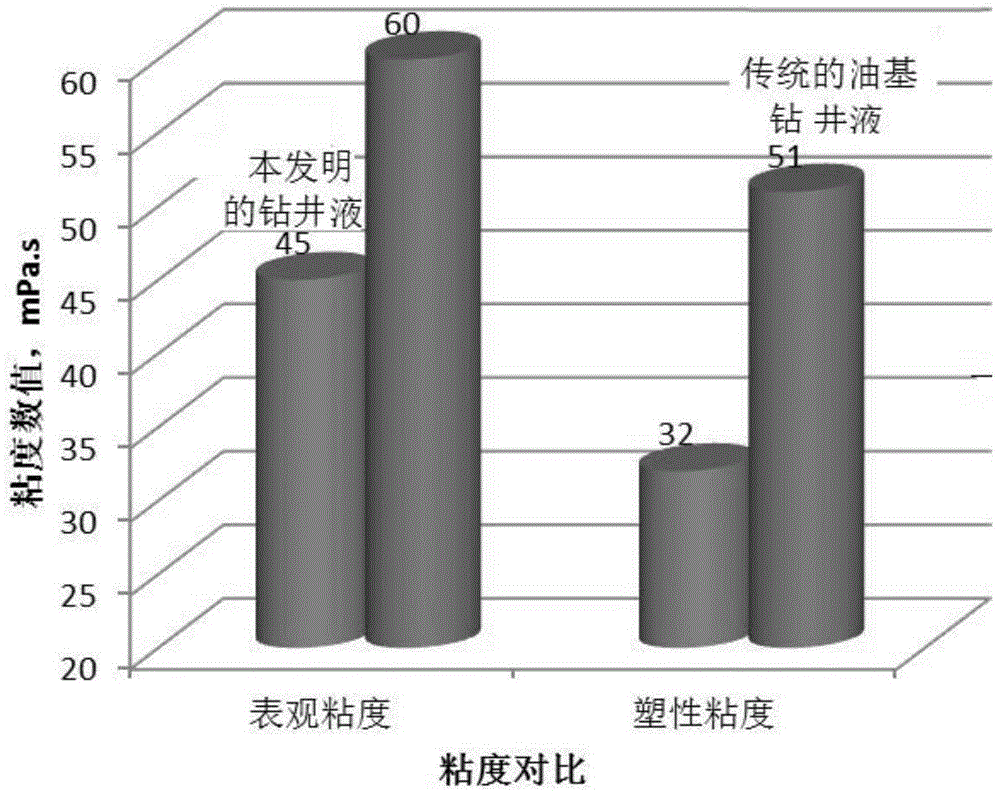

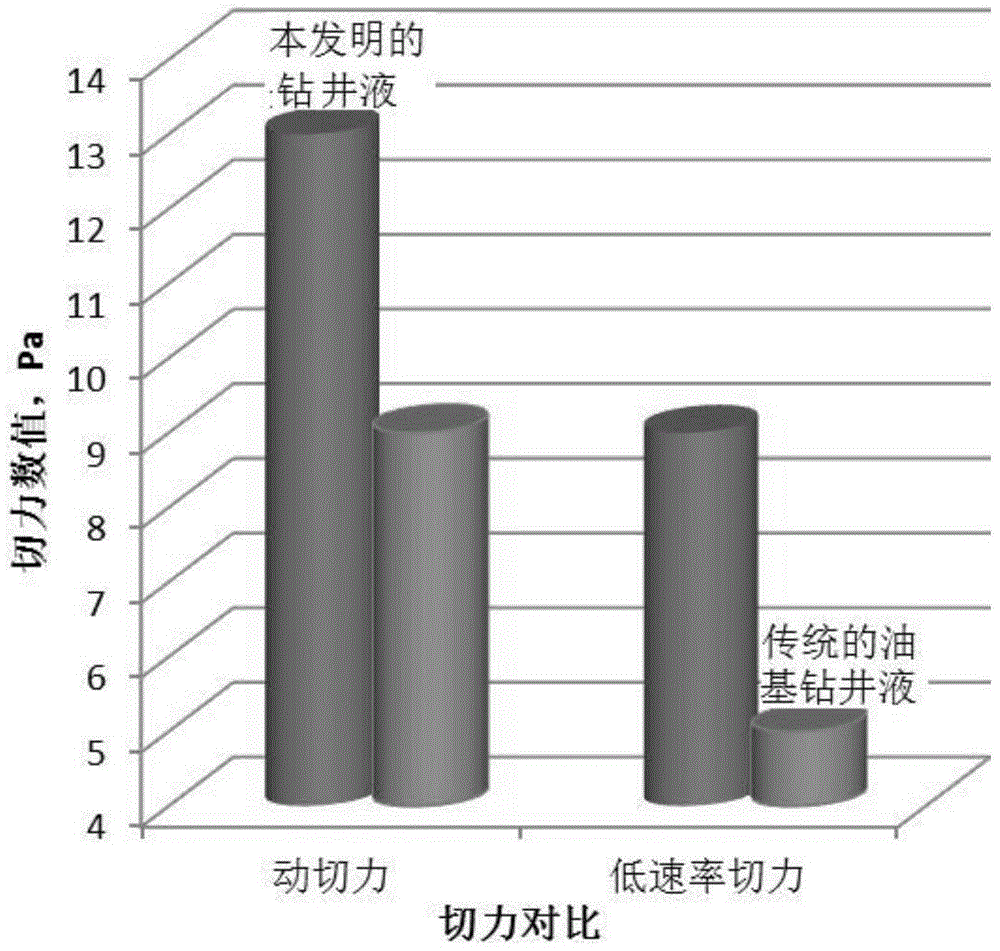

[0026] Test 1: The rheological performance test of the oil-based drilling fluid of embodiment 1 under different densities

[0027] According to the above steps, the density is 1.6g / cm3 3 , 1.8g / cm 3 , 2.0g / cm 3 and 2.2g / cm 3 After hot rolling at 150°C for 16 hours, perform the following performance tests according to the regulations in "GB / T16783.2-2012 Oil and Gas Industry Drilling Fluid Field Test Part 2 Oil-based Drilling Fluid", the results are sho...

Embodiment 2

[0048] Measure 340mL of white oil into a 500mL high stirring cup, add 12.0g of emulsifier G326 and 8.0g of calcium hydroxide (accurate to 0.0lg) while stirring with a high-speed stirrer, and slowly add 60mL of CaCl after stirring for 10 minutes 2 Brine, 8.0g fluid loss reducer G328, 2.0g viscosifier G336-VIS, and 8.0g shear lifter G322-MOD were stirred at a high speed for 90 minutes, interrupted every 20 minutes to scrape off the slurry adhering to the cup wall. That is, the oil-based drilling fluid of the present invention is obtained.

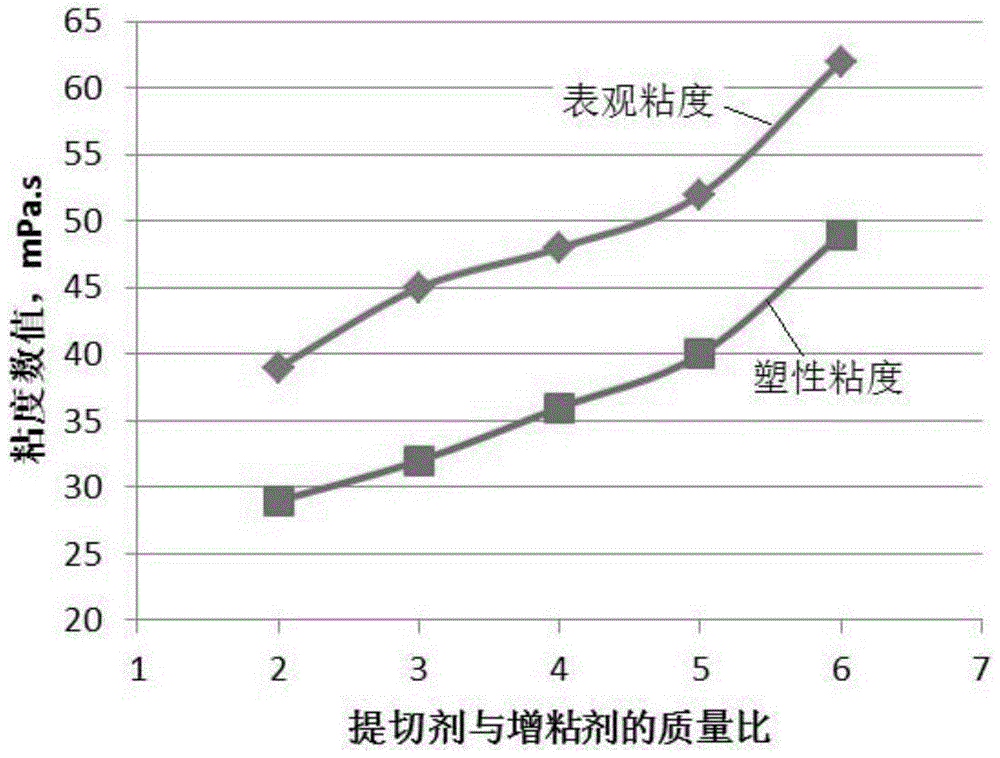

[0049] Test 5: Comparative test of the rheological properties of the drilling fluid at different ratios (mass ratio of viscosifier to shear raising agent) of Example 2.

[0050] The oil-based drilling fluid formula is as follows: the mass percentage ratio of base oil to calcium chloride brine is 80:20, 3.0% emulsifier, 2.0% calcium hydroxide, and 2.0% fluid loss reducer based on the total weight of oil-based drilling fluid , Cutting agent, t...

Embodiment 3

[0053] Measure 360mL of base oil into a 500mL high stirring cup, add 9.0g of emulsifier G326 and 12.0g of calcium hydroxide (accurate to 0.0lg) while stirring with a high-speed stirrer, slowly add 40mL of CaCl after stirring for 10min 2 Brine, 12.0g of fluid loss additive G328, 3.0g of viscosifier G336-VIS and 6.0g of shearing agent G322-MOD were stirred at high speed for 90 minutes in total, interrupted every 20 minutes to scrape off the slurry adhering to the cup wall. That is, the oil-based drilling fluid of the present invention is obtained.

[0054] Test 6: Comparative test of the rheological properties of oil-based drilling fluids formulated with different base oils in Example 3

[0055] The formula of embodiment 3 uses different base oils to prepare density 2.0g / cm respectively 3 After hot rolling at 150°C for 16 hours, perform the following performance tests according to the provisions in "GB / T16783.2-2012 Oil and Gas Industry Drilling Fluid Field Test Part 2 Oil-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com