Attapulgite/carbon black composite suspension and preparation method, composite material and application

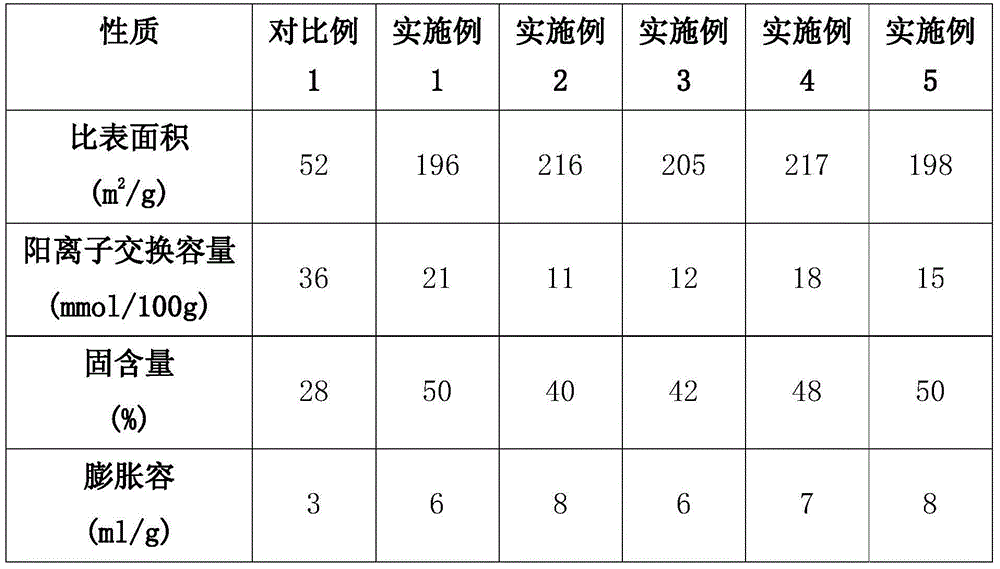

A technology of attapulgite and nanocomposite materials, applied in the field of preparation of attapulgite/carbon black suspension, which can solve the problems of low solid content and poor reinforcement performance, and achieve large specific surface area, increased expansion capacity, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In order to overcome the deficiencies in the prior art, while making attapulgite / carbon black have good water suspension properties and affinity properties with rubber macromolecular chains, attapulgite / carbon black suspensions with high solid content are prepared, for Preparation of rubber-based attapulgite / carbon black nanocomposites by emulsion co-flocculation and co-coagulation lays a solid foundation. The present invention proposes a kind of preparation method of attapulgite / carbon black composite suspension, comprises the following steps:

[0033] Step 1: Purifying the attapulgite;

[0034] Step 2: activating the attapulgite after purification in step 1;

[0035] Step 3: Surface modification of attapulgite / carbon black: adding carbon black with a mass of attapulgite 1-5 times the mass of attapulgite and the total mass of attapulgite and carbon black to the activated attapulgite in step 2 1%-5 % of at least two or more surface modifiers, maintain the temperature ...

Embodiment 1

[0057] (1) Purification of attapulgite: Add the attapulgite raw ore into the pulverizer, the size of the crushed particles is 200 mesh, add water twice the mass to the attapulgite particles, and add purification to the attapulgite slurry. The modified dispersant sodium hexametaphosphate is stirred at a high speed for 10 minutes, and the stirring speed is 3000r / min, and the impurities in the attapulgite slurry are removed through a 100-mesh sieve to obtain the primary product of the attapulgite suspension;

[0058] (2) Activation of the attapulgite: while heating, add a concentration of 10% sulfuric acid solution to the prepared attapulgite suspension primary product, control the pH of the solution to be 3, activate for 1.5 hours; then maintain the temperature of the solution Constant, add sodium hydroxide particle wherein under continuous stirring, the pH value of control solution is 6.5, and this process maintains 1.2 hours;

[0059] (3) Surface modification of attapulgite / ca...

Embodiment 2

[0061] (1) Purification of attapulgite: Add the attapulgite raw ore into the pulverizer, the size of the crushed particles is 200 mesh, add water 3 times the mass to the attapulgite particles, add purification to the attapulgite slurry The modified dispersant sodium pyrophosphate is stirred at a high speed for 8 minutes, and the stirring speed is 2500r / min, and the impurities in the attapulgite slurry are removed through a 100-mesh sieve to obtain the preliminary product of the attapulgite suspension;

[0062] (2) Activation of attapulgite: while heating, adding concentration to the prepared attapulgite suspension primary product is 10% sulfuric acid solution, controlling the pH value of the solution to be 4, and activating for 2 hours; then maintaining the temperature of the solution Constantly, sodium hydroxide particles are added thereto under continuous stirring to control the pH of the solution to be 7.5, and the process is maintained for 1.5 hours;

[0063] (3) Surface m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com