Two-end functionalized ternary copolymer rubber and preparation method thereof

A ternary copolymer rubber and double-end technology, applied in the field of new ternary copolymer rubber, can solve the problems of low degree of functionalization of alkoxy groups, unstable functionalized initiator, unable to maintain the growth of active ends, etc., to achieve solubility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

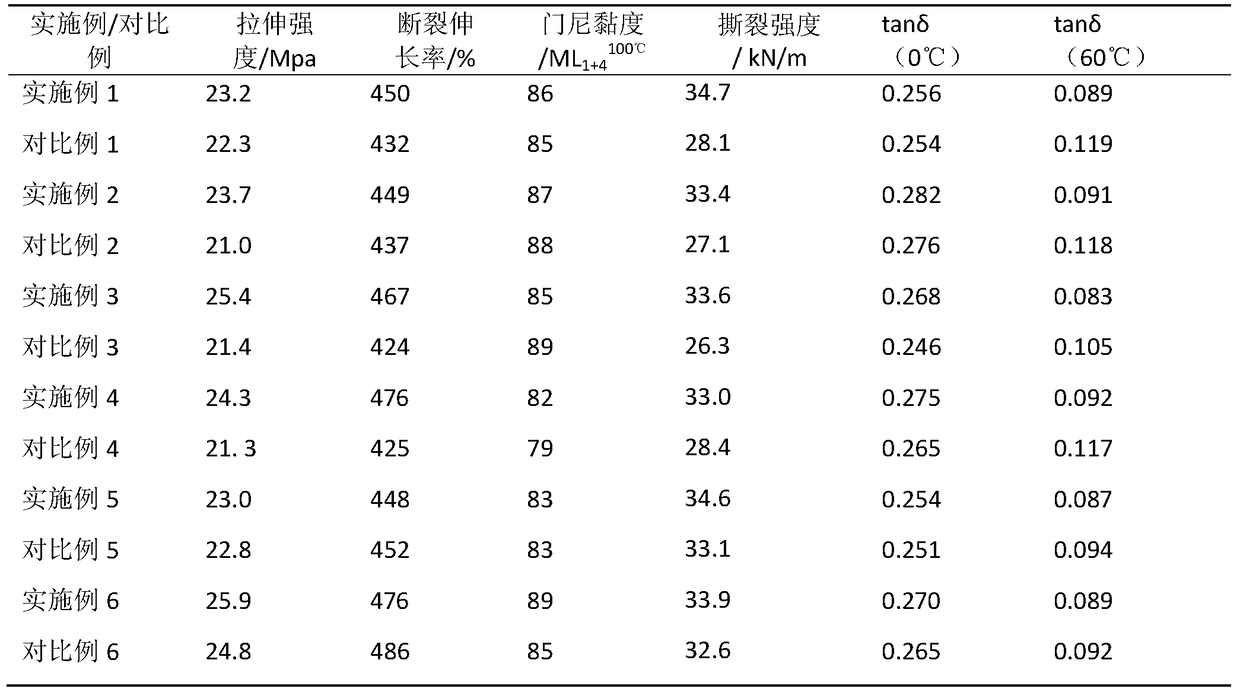

Examples

Embodiment 1

[0025] Under the protection of anaerobic, anhydrous, and argon, add 700ml of hexane and 3mol of metal lithium wire into a 1000ml three-necked flask equipped with a condenser, dropping funnel, and magnetic stirrer, raise the temperature to 50°C, and add Add 1.36 mol of trimethoxy (4-chlorobutoxy) silane solution slowly (dropping rate: 0.03 mol / min) into the three-necked flask, stir while adding, and use cold oil to lower the temperature, and control the reaction temperature at 50-60°C , the dropwise addition time is 1h, after the dropwise addition is complete, the constant temperature reaction is continued for 2h, the crude product is filtered under an inert atmosphere to obtain a functionalized initiator, and finally an organolithium initiator containing silicon ether is obtained for future use.

[0026] In a jacketed 15L stainless steel polymerization kettle, the system was replaced 3 times with argon gas. Add 2654g of cyclohexane, 400g of isoprene, and 0.12g of tetrahydrofur...

Embodiment 2

[0030] Under the protection of anaerobic, anhydrous, and argon, add 700ml of hexane and 3mol of metal lithium wire into a 1000ml three-necked flask equipped with a condenser, dropping funnel, and magnetic stirrer, raise the temperature to 50°C, and add Add 1.36 mol of triethoxy (4-chlorobutoxy) silane solution slowly into a three-necked flask (dropping speed 0.05 mol / min), stir while adding, and use cold oil to cool down, and control the reaction temperature at 50-60°C , the dropwise addition time is 1h, after the dropwise addition is complete, the constant temperature reaction is continued for 2h, the crude product is filtered under an inert atmosphere to obtain a functionalized initiator, and finally an organolithium initiator containing silicon ether is obtained for future use.

[0031] In a jacketed 15L stainless steel polymerization kettle, the system was replaced 3 times with argon gas. Add 1991 g of cyclohexane, 300 g of isoprene, and 0.08 g of tetrahydrofuran into the ...

Embodiment 3

[0035] The preparation of the functionalized catalyst was the same as in Example 1.

[0036] In a jacketed 15L stainless steel polymerization kettle A, the system was replaced 3 times by passing argon. Add 3318g of cyclohexane, 500g of isoprene, and 0.18g of tetrahydrofuran into the polymerization kettle, add 5.0mmol of n-butyllithium, raise the temperature to 70°C, and polymerize for 60min. After the monomer is completely converted, add 2674g of cyclohexane, butane Diene 240g, styrene 160g, tetrahydrofuran 0.24g, reaction temperature 70°C, polymerize for 70min, add cyclohexane 652g, butadiene 100g after complete monomer conversion, maintain reaction temperature 70°C, continue to react for 60min, after the completion of the reaction, pass Inject carbon dioxide gas to carry out capping reaction, and the reaction time is 20min. After the end-capping reaction is completed, add 10 g of antioxidant 1010 [tetrakis-(4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaerythritol ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com