Two-way medicine plate conveying mechanism

A two-way conveying and drug board technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as inconvenient control, high production cost, and complex transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

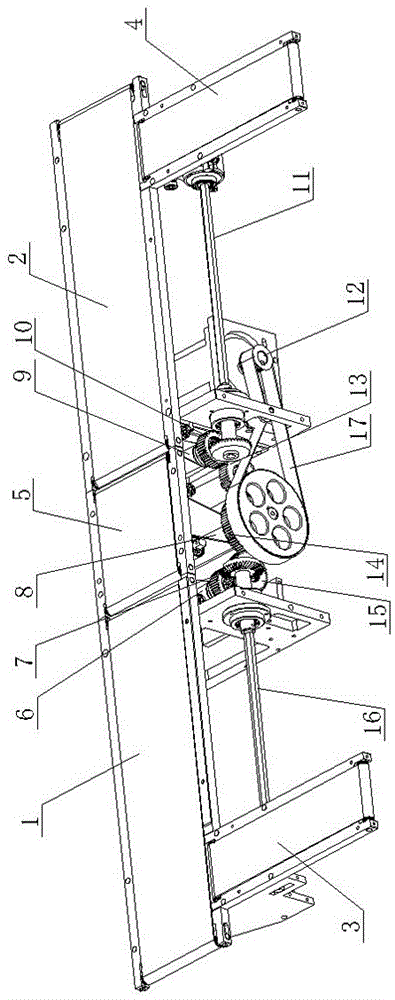

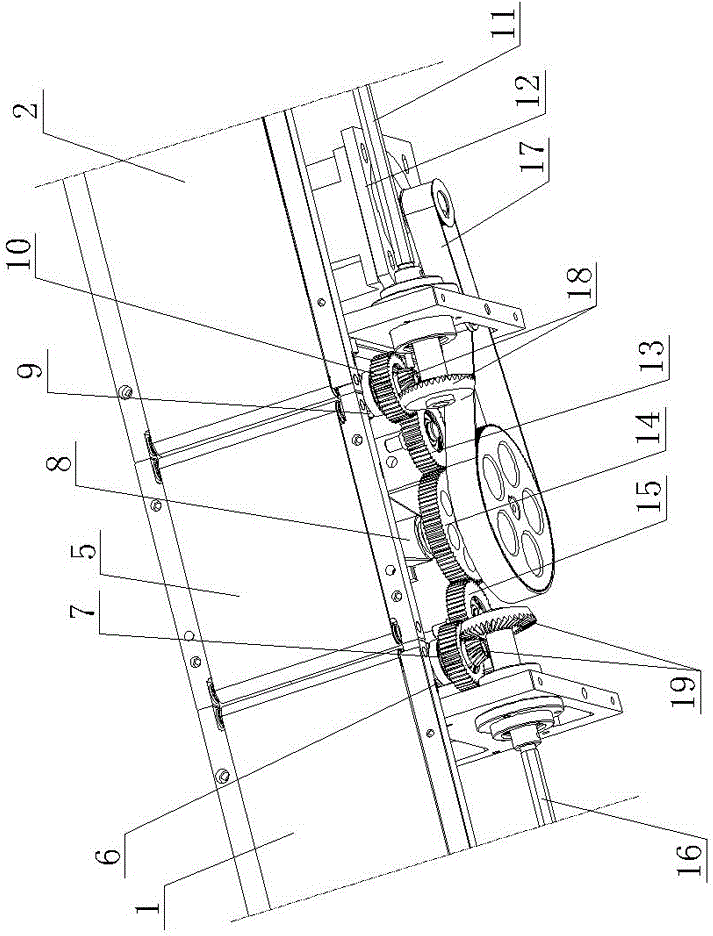

[0012] As shown in the figure, the two-way conveying mechanism for medicine boards of the present invention includes an intermediate conveyor belt 5, the left end of the intermediate conveyor belt 5 is connected to the first conveyor belt 1, the left end of the first conveyor belt 1 is connected to the third conveyor belt 3, and the right end of the intermediate conveyor belt 5 is connected to the third conveyor belt 3. Connect the second conveyor belt 2, the right end of the second conveyor belt 2 is connected to the fourth conveyor belt 4, the setting direction of the first and second conveyor belts is the same as that of the middle conveyor belt, the setting direction of the third and fourth conveyor belts is the same as that of the middle conveyor belt The direction is vertical, the transmission of the intermediate conveyor belt 5 is driven by the intermediate transmission shaft 8, the intermediate transmission shaft 8 and the motor 12 are connected through the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com