Thermoplastic composite material joint connecting method

A composite material and joint connection technology, applied in the field of thermoplastic composite material repair, can solve the problems of short service life, difficulty in repairing damage, weak mechanical properties of connecting parts, etc., to improve mechanical properties and reliability, reduce environmental sensitivity, reduce The effect of practical risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for connecting thermoplastic composite joints provided by the present invention will be described in detail below in conjunction with specific embodiments.

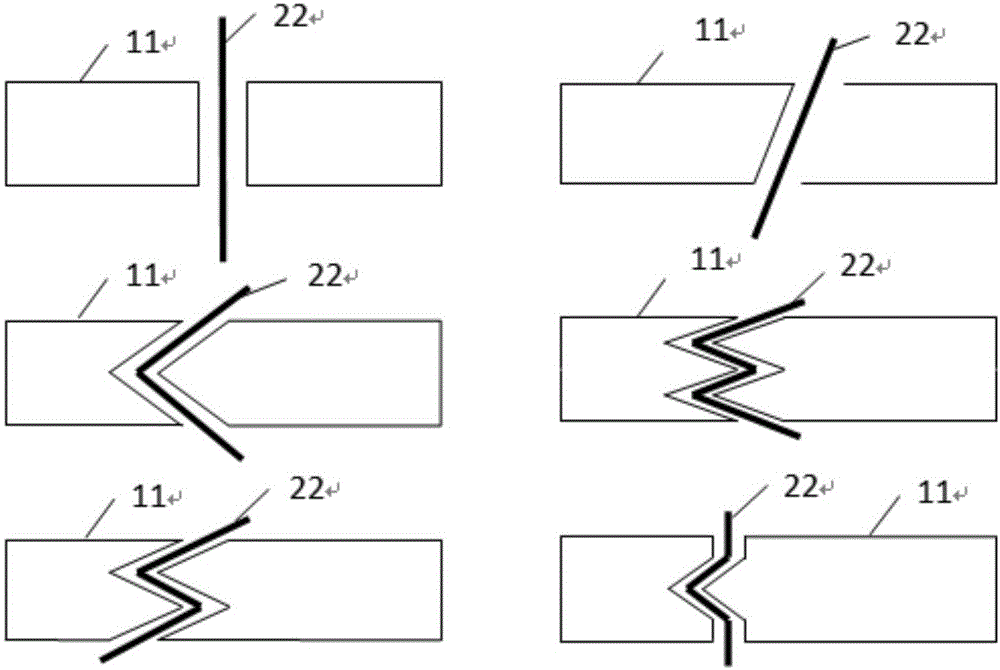

[0020] Such as figure 1 — Figure 4 As shown, the thermoplastic composite material joint connection method provided by the present invention includes the following steps carried out in order:

[0021] 1) Pretreating the joints of the two thermoplastic composite materials 11 to be connected; the pretreatment method is to first polish the joints, then clean them with absolute ethanol and dry them;

[0022] 2) Fix the above-mentioned thermoplastic composite material 11 on the fixture in such a way that the joints are opposite or overlapping, pay attention to the force exerted by the fixture so that the thermoplastic composite material 11 cannot be deformed or damaged, and ensure that the thermoplastic composite material 11 is connected during the welding process intact;

[0023] 3) Clamp the carbon fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com