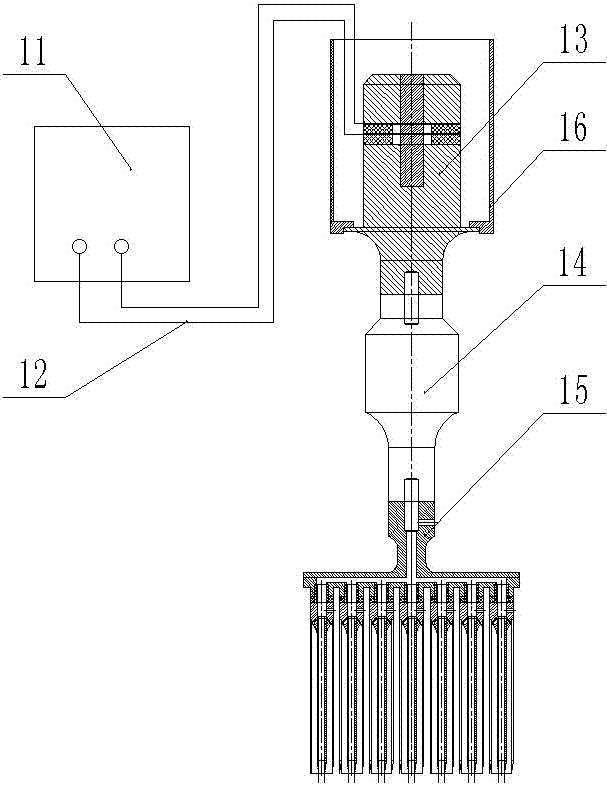

A high-frequency vibrating sponge array strip-taking device and its application

A high-frequency vibration and sponge technology, applied in metal processing, etc., can solve the problems of simultaneous multi-hole processing, difficulty in strip control, pollution, etc., and achieve the effects of expanding the scope of use, broad market prospects, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

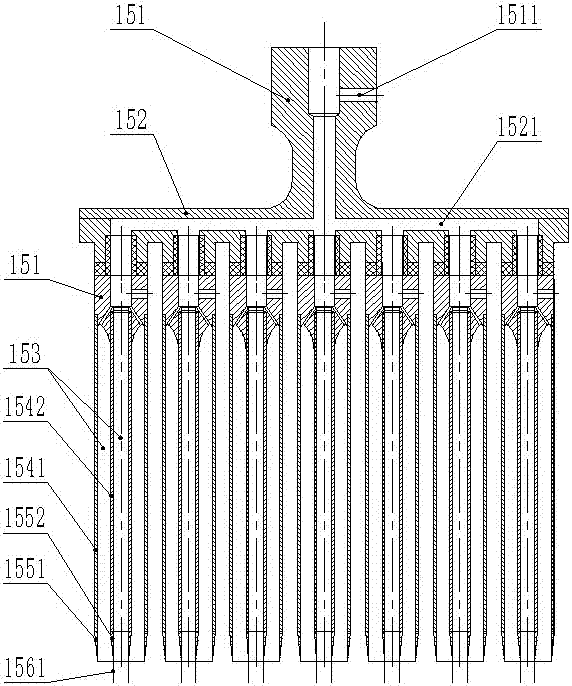

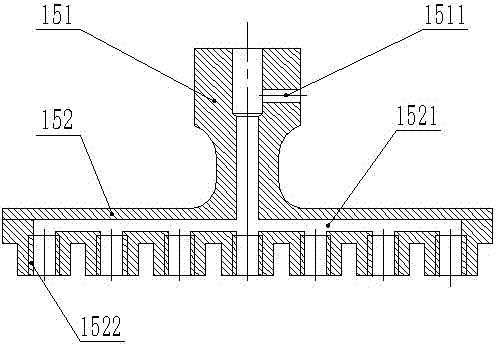

[0041] Such as figure 2 As shown, the multi-tube cutter 15 includes a connecting head 151 connected to the horn 14, a pipe body mounting plate 152 connected to the connecting head 151, and an internal cavity 153 is set on the pipe body mounting plate 152. The inner tube body 1542 and the outer tube body 1541, the inner cutting edge 1552, the outer cutting edge 1551, the first positioning pin 1561 and the second positioning pin 1562.

[0042] Such as image 3 As shown, the tube body installation plate 152 is integrally formed with the connector 151, the connector 151 is provided with a channel 1511, the tube body installation plate 152 is provided with an air distribution channel 1521, and one end of the channel 1511 is connected to the external The air compressor (not shown in the figure) is connected, and the other end is connected with the main head of the air distribution channel 1521, such as figure 2 As shown, each branch of the branch air channel 1521 communicates wi...

Embodiment 2

[0053] The difference from Embodiment 1 is that the tube body mounting plate 152 also includes a cover 1523 for the internally threaded hole 1522 . It is used to close the internally threaded hole 1522 that is not connected to the pipe body 154 .

[0054] For example, when the diameter of the pre-processed cylindrical hollow strip body 20 is relatively large, such as Figure 8 As shown, the external thread head 1533 of the pipe body 154 matches the internal thread hole 1522, and the cavity 153 matches the size of the pre-processed hole.

[0055] Since the outer diameter of the tube becomes larger, the tube body 154 cannot be sequentially arranged on the tube body mounting plate 152 , and the unused internal threaded hole 1522 is closed by the cover 1523 .

[0056] Using the processing process described in Embodiment 1, the processing of multiple cylindrical hollow strip blanks 20 can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com