Wire drawing machine used for screw production

A wire drawing machine and screw technology, applied in the field of screw processing equipment, can solve the problems of restricting product quality, increasing the variety of output, manual unloading, and small reel weight, so as to achieve convenient and fast wire take-up, improve production efficiency, and large capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

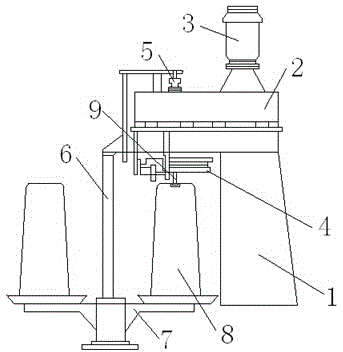

[0013] like figure 1 A wire drawing machine for screw production shown includes a base 1, and a gear box 2 arranged on the upper end of the base 1; the upper end of the gear box 2 is connected to a motor 3, and the lower end is connected to a drawing coil cylinder 4; one side of the gear box 2 is connected with a column 6 through a connecting rod 5; a rotating platform 7 is installed at the lower end of the column 6;

[0014] Wherein, there are two wire take-up racks 8, and the structure is symmetrical with the column 6 as the axis of symmetry.

[0015] The upper end of a take-up frame 8 is connected to the drawing reel 4 through a rotating shaft 9 .

[0016] The wire drawing machine used for screw production of the present invention is convenient for unloading the wire through the two take-up stands, and the take-up stand has a large capacity; the set rotating platform makes the take-up of the wire take-up convenient and fast, and improves the production efficiency; Its str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com