Method for preparing quaternary sulfide quantum dot based heterojunction efficient photocatalyst

A photocatalyst and heterojunction technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic degradation efficiency and low specific surface area, and achieve simple process, dispersed Good performance and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0015] Example 1AgIn 5 S 8 -ZnS / MoS 2 Preparation of Heterojunction Composite Photocatalyst

[0016] 300mgAgIn 5 S 8 -ZnS nanocrystals were added to 35mL aqueous solution containing ammonium molybdate tetrahydrate and thiourea respectively, magnetically stirred, and the mass ratio of the complex was controlled to be 1%, 5%, 10%, 15%, 30%, and the The hydrothermal reaction was carried out for 8 hours. After the reaction, the obtained product was washed with deionized water / ethanol, filtered, and dried in a constant temperature drying oven at 60°C.

Embodiment 2A

[0017] Example 2AgIn 5 S 8 -ZnS / MoS 2 Characterization and Analysis of Heterojunction Composite Photocatalysts

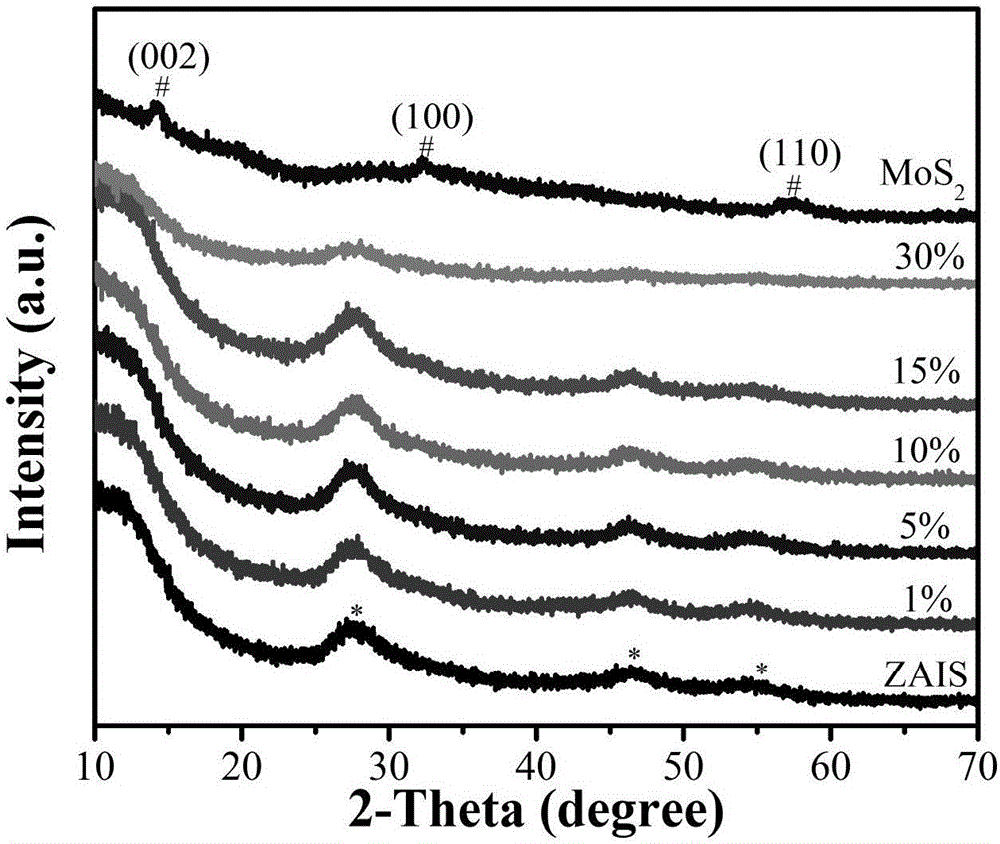

[0018] Such as figure 1 As shown, it can be seen from the figure that although with the MoS 2 The increase in the amount is still mainly AgIn 5 S 8 -The peak of ZnS nanocrystals does not appear in MoS 2 peak.

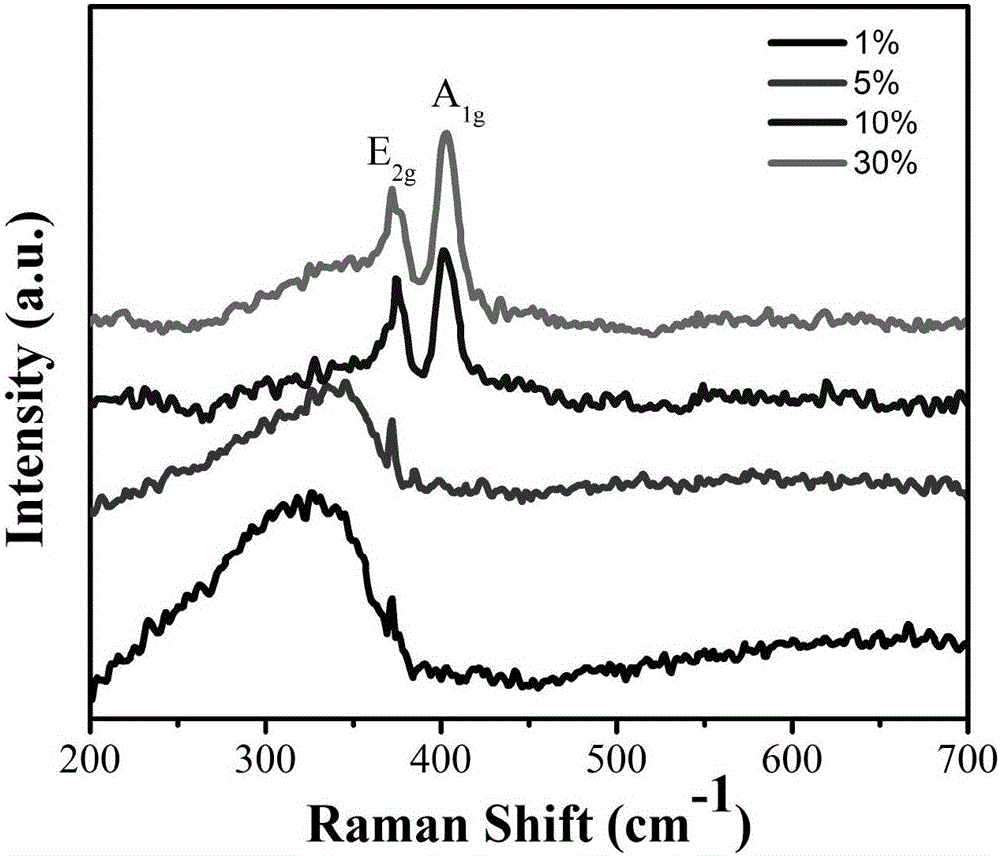

[0019] Such as figure 2 As shown, it can be seen from the figure that there is a fluorescence peak when the recombination amount is low, and as the MoS 2 The amount of increase, MoS 2 The Raman characteristic peaks gradually increased, indicating that AgIn was successfully prepared 5 S 8 -ZnS / MoS 2 Heterojunction composite photocatalysts.

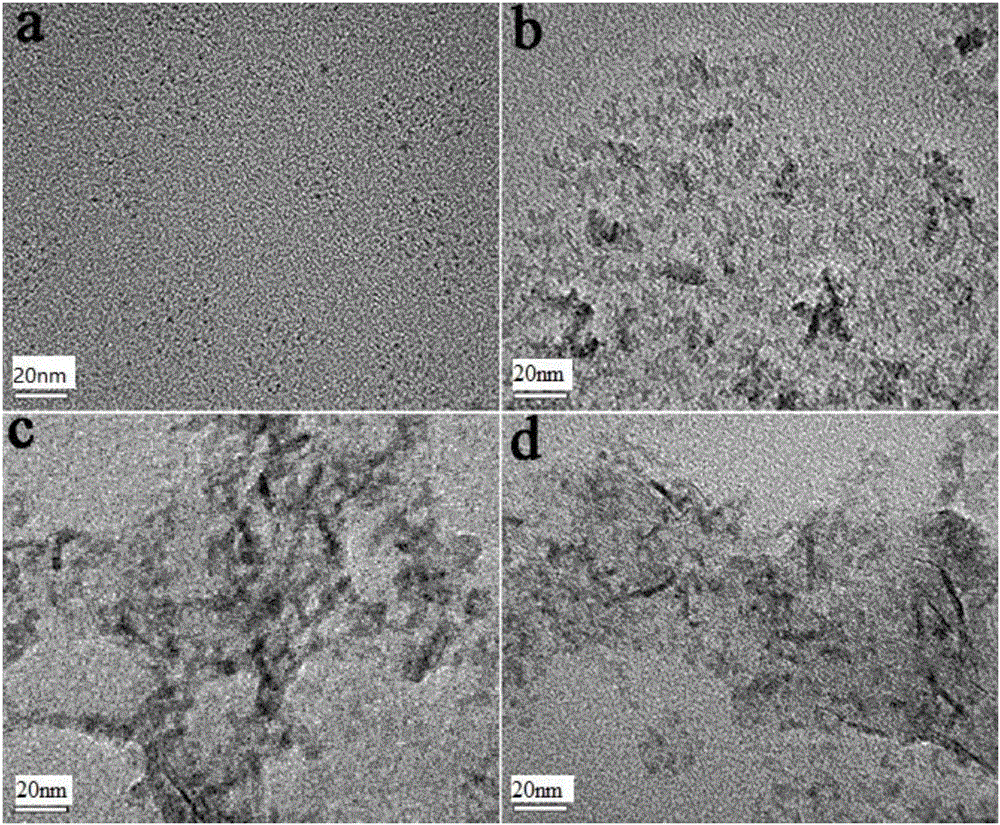

[0020] Such as image 3 As shown, it can be seen from the figure that AgIn 5 S 8 -ZnS nanocrystals are only a few nanometers, with MoS 2 The amount of increase, MoS 2 Gradually grow into flakes by aggregation.

[0021] Such as Figure 4 As shown in the figure, it can be clearly seen that the AgIn 5 S ...

Embodiment 3A

[0022] Example 3AgIn 5 S 8 -ZnS / MoS 2 Visible light catalytic activity experiments of heterojunction composite photocatalysts

[0023] (1) Prepare a rhodamine B solution with a concentration of 10 mg / L, and place the prepared solution in a dark place.

[0024] (2) Weigh AgIn 5 S 8 -ZnS / MoS 2 Put 10mg of heterojunction composite photocatalyst into the photocatalytic reactor respectively, add 100mL of the target degradation solution prepared in step (1), and stir magnetically for 60 minutes. After the composite photocatalyst is uniformly dispersed, turn on the water source and light source to carry out photocatalysis Degradation experiment.

[0025] (3) Draw up the photocatalytic degradation solution in the reactor every 2 minutes, and use it for the measurement of the ultraviolet-visible absorbance after centrifugation.

[0026] (4) by Figure 4 It can be seen that the prepared nano-heterojunction composite photocatalyst has excellent visible light catalytic activity, esp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com