Calcium-based CO2 adsorbent and preparing method thereof

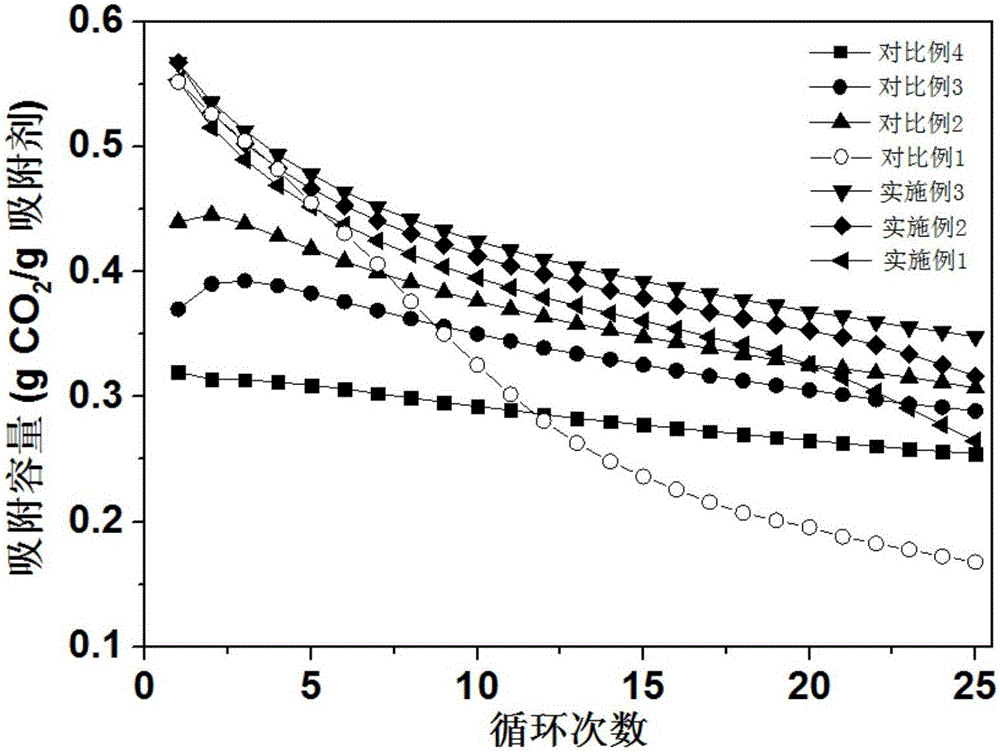

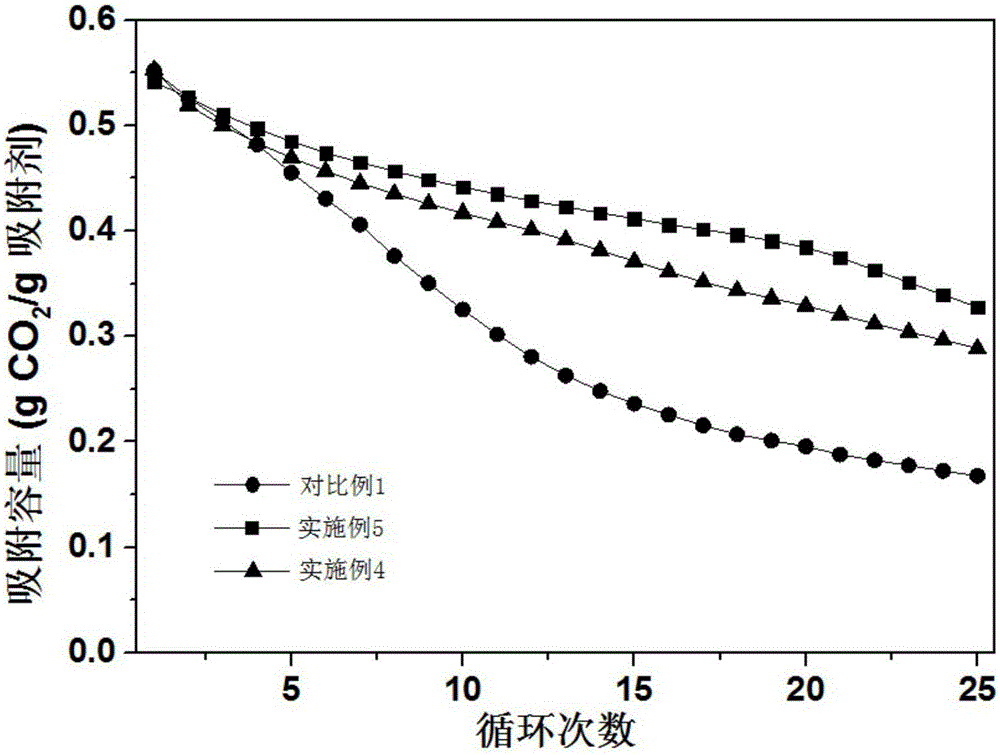

An adsorbent, calcium-based technology, applied in the field of calcium-based CO2 adsorbent and its preparation, can solve the problems of poor circulation stability of calcium oxide adsorbent, loss of active calcium oxide adsorbent, unfavorable fluidization of adsorbent particles, etc. The granulation method is simple and easy to implement, improves the cycle stability, and the effect of good CO2 adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The Ca-based CO 2 The preparation method of adsorbent comprises the following steps:

[0029] (1) Evenly mix the algae raw material, water and calcium-based raw material with a mass ratio of 0.001:0.1:1 to 0.03:0.45:1 to obtain a mixed material; wherein the calcium-based raw material is calcium hydroxide, calcium carbonate or slaked lime One or more of them, the particle size of which is less than 200 μm;

[0030] (2) extruding and spheronizing the mixed material to obtain a spherical mixed material with a diameter less than 4mm;

[0031] (3) Dry the spherical mixture (such as air-drying or drying for 5h-10h below 60°C, so as not to cause the adsorbent to react with CO in the air if the temperature is too high. 2 reaction to affect its adsorption performance) and sieve out spherical particles with a diameter of 0.3 mm to 3.5 mm to obtain the calcium-based CO 2 Adsorbent.

[0032] Wherein, the extrusion spheronization of the step (2) is usually operated by an extrusi...

Embodiment 1

[0033] Example 1 Preparation of calcium oxide-based adsorbent pellets doped with microalgae

[0034] (1) Add 15ml of deionized water to 40g of calcium hydroxide powder with a particle size of less than 150 μm and 0.2g of microalgae powder and stir well.

[0035] (2) Pass the obtained wet material through a single-screw extruder, the aperture of the extrusion template is 1mm, and the extrusion speed is 30r / min, to obtain long cylindrical adsorbent particles. Then, put the long cylindrical particles into the spheronizer, first set the speed at 1400r / min and last for 2min, cut the long cylindrical calcium oxide particles at 1400r / min2min into short cylindrical particles, then reduce the speed to 1000r / min and last for 5min , Roll short cylindrical particles into calcium oxide pellets.

[0036] (3) Finally, the obtained calcium oxide pellets are screened through a standard sieve, and the pellets with a particle size range of 0.9 mm to 1.25 mm are placed in the air to dry for 24 h...

Embodiment 2

[0037] Example 2 Preparation of calcium oxide-based adsorbent pellets doped with microalgae

[0038]Repeat Example 1 with the same steps described, the difference is that the quality of the microalgae powder is 0.4g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com