an accelerator tube

A technology of accelerating tube and accelerating cavity, which is applied in the field of accelerating tube, can solve the problems of limited adjustment range, weakened beam-forming effect, and poor capture rate of beam current at the exit of accelerating tube, and achieves stable operation and small frequency disturbance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

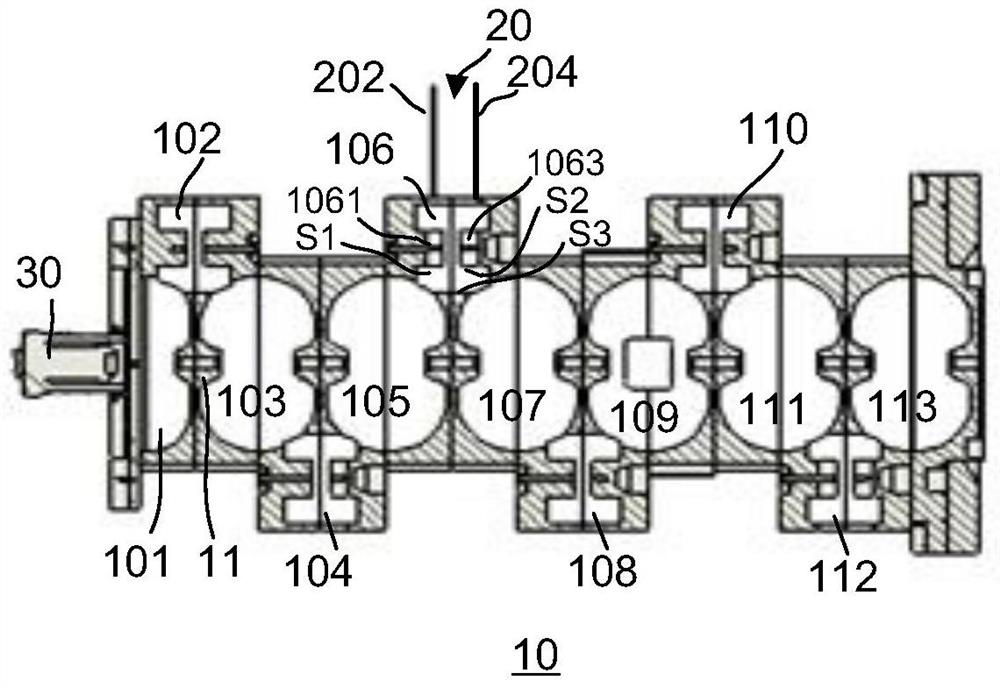

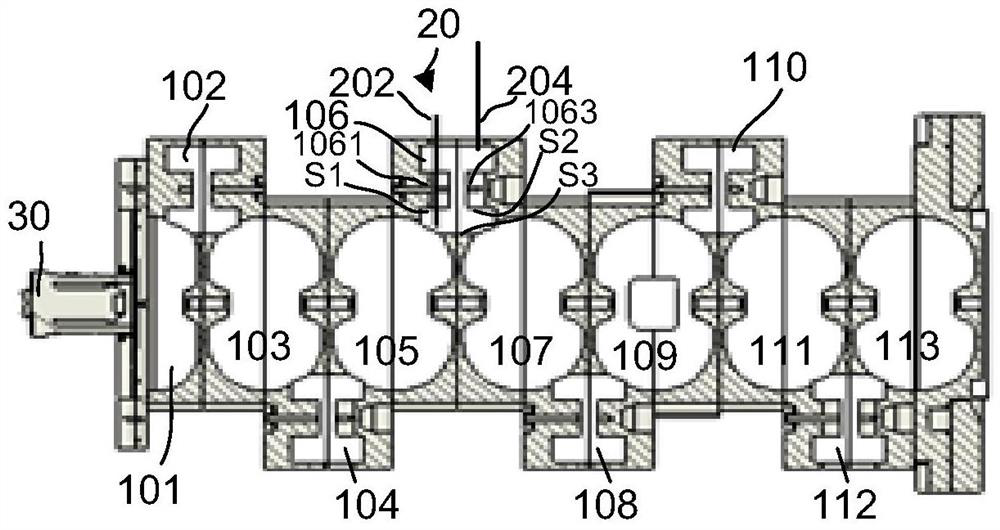

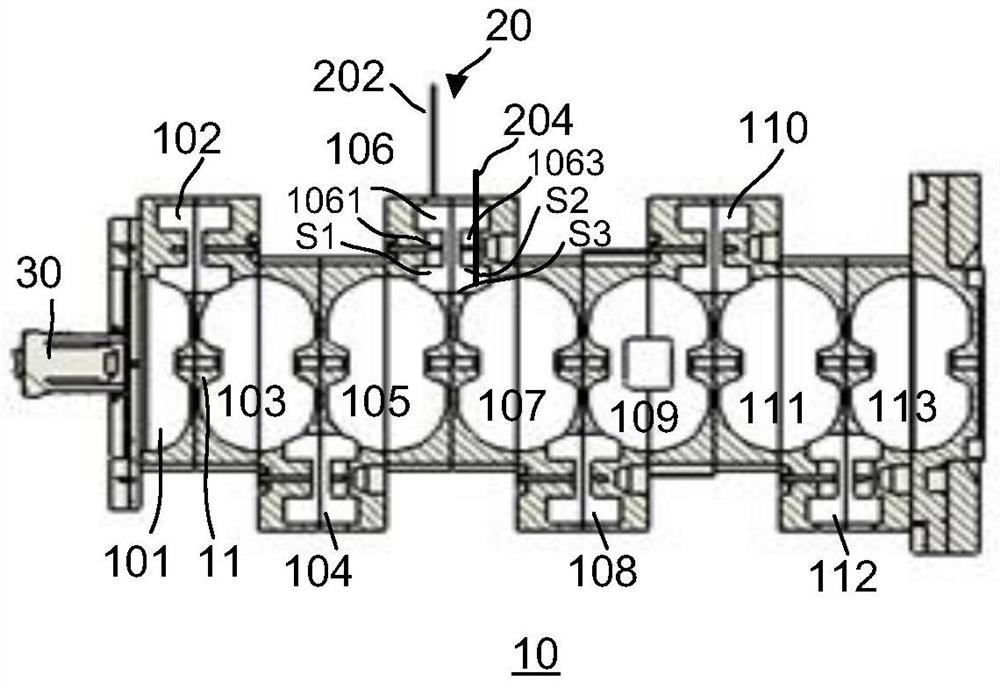

[0027] like Figure 1-Figure 3 shown, according to one embodiment of the present invention, figure 1 is a schematic diagram of the structure of the accelerating tube when it is in the first mode, figure 2 is a schematic diagram of the structure of the accelerating tube when it is in the second mode, image 3 It is a schematic diagram of the structure of the accelerating tube when it is in the third mode.

[0028]Specifically, the accelerating tube 10 is a standing wave accelerating tube. One end of the accelerating tube 10 may be coupled to an electron gun 30 that generates an electron beam, and the other end of the accelerating tube 10 may be coupled to a target assembly such that the electron beam emitted from the accelerating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com