QLED device and preparation method thereof

A device and substrate technology, applied in the field of QLED devices and their preparation, can solve the problems of low crystallinity, many structural defects, limited transmission and light transmittance of the electron transport layer, etc. Effects of transmission and light transmission, quenching reduction, structural defect reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

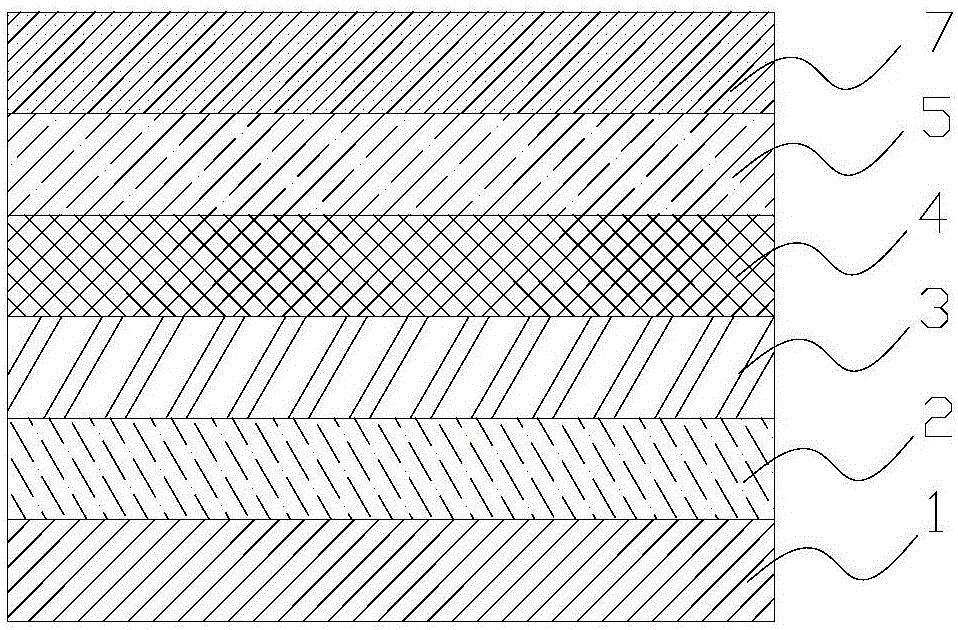

[0020] The embodiment of the present invention provides a method for preparing a QLED device, comprising the following steps:

[0021] S01. A substrate is provided, and a bottom electrode is formed on the substrate;

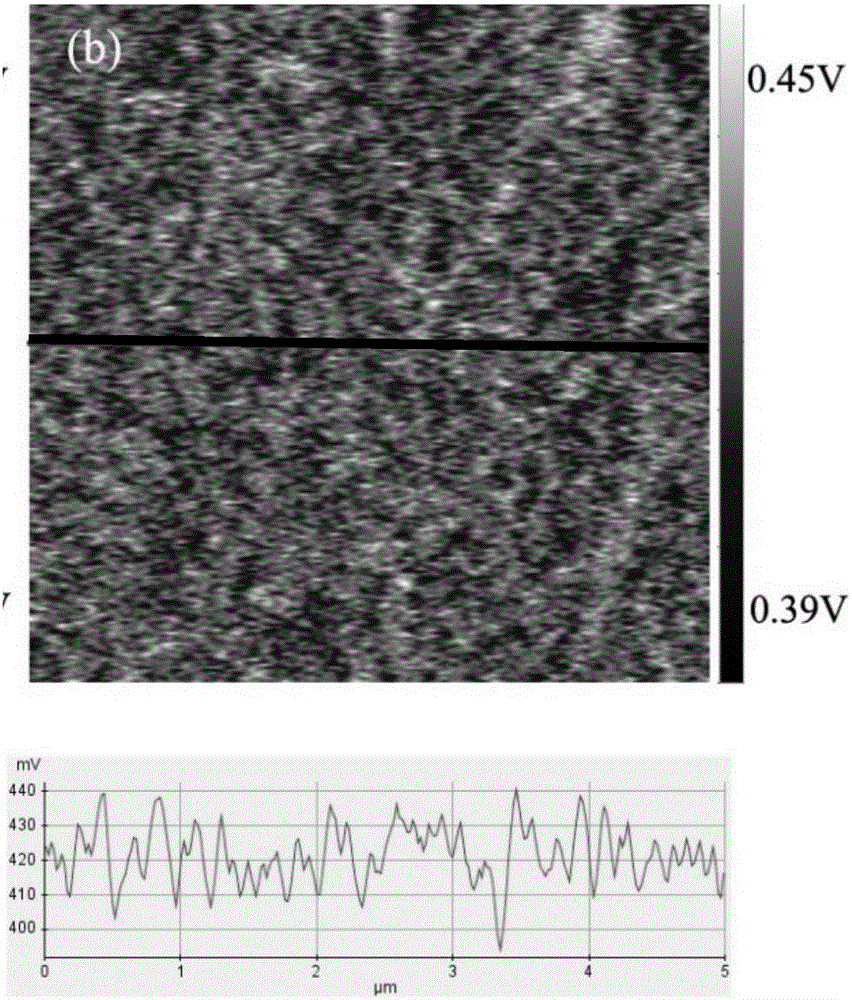

[0022] S02. Depositing an electron transport material on the bottom electrode, and performing RTP treatment on the electron transport material to obtain an electron transport layer;

[0023] S03. Depositing an interface modification material on the electron transport layer to form an interface modification layer, and the interface modification material is a material with a permanent dipole moment;

[0024] S04. Depositing a quantum dot light-emitting layer and a top electrode sequentially on the interface modification layer.

[0025] Specifically, in the above step S01, the choice of the substrate is not limited, a flexible substrate may be selected, and a hard substrate such as a glass substrate may also be selected. The method for forming the bottom electrode...

Embodiment 1

[0040] A method for preparing a QLED device, comprising the following steps:

[0041] S11. providing a substrate, forming a bottom electrode on the substrate;

[0042] S12. Deposit nano-zinc oxide on the bottom electrode, and perform RTP treatment on the nano-zinc oxide to obtain an electron transport layer, wherein the RTP treatment method is heat preservation treatment at 300°C in air for 30s;

[0043] S13. Depositing an interface modification material on the electron transport layer to form an interface modification layer, and the interface modification material is a material with a permanent dipole moment;

[0044] S14. Depositing a quantum dot light-emitting layer, a hole transport layer and a top electrode sequentially on the interface modification layer.

Embodiment 2

[0046] A method for preparing a QLED device, the method differs from that of Example 1 in that in the step of preparing an electron transport layer, the RTP treatment is heat preservation at 300°C for 30s in vacuum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com