Oil film pressure display module based on dynamic pressure bearing teaching

A technology of oil film pressure and dynamic pressure bearings, applied in teaching models, educational tools, instruments, etc., can solve the problems of not being familiar with and mastering the engineering knowledge of fluid dynamic pressure lubrication, uneven force on the upper plate, and influence, etc., so as to improve classroom efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

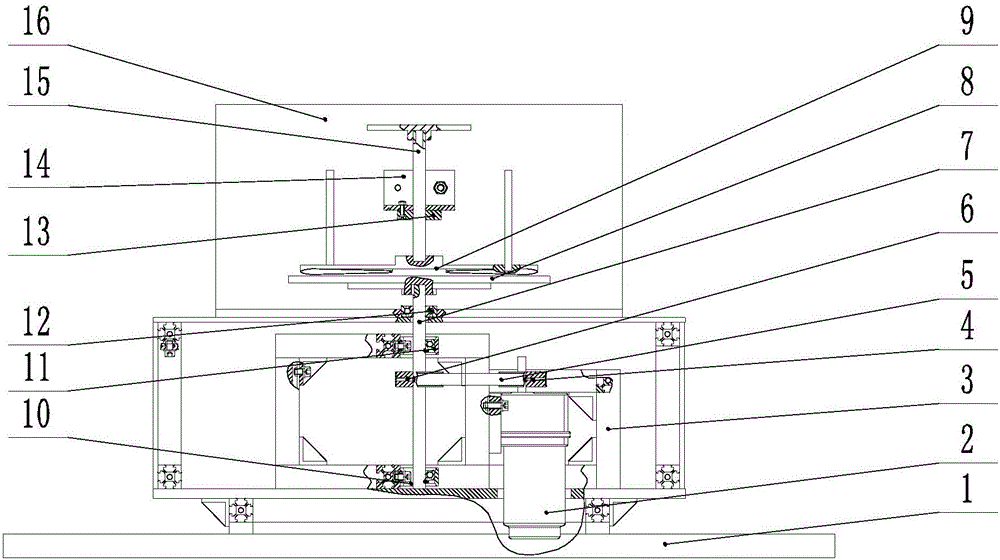

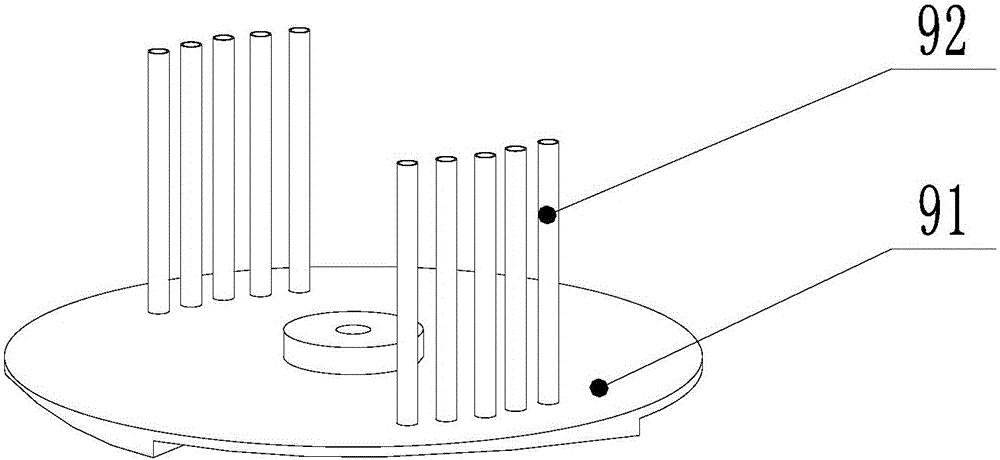

[0038] refer to figure 1 , the oil film pressure display module based on the teaching of dynamic pressure bearings, including an experimental platform 1, a motor 2 is installed on the experimental platform 1, the motor shaft of the motor 2 is connected to a transmission module, and the transmission module is connected to A main shaft 7, the upper end of the main shaft 7 is keyed to a turntable 8, the upper surface of the turntable 8 is provided with an oil film pressure display device 9, and the oil film pressure display device 9 includes a wedge-shaped disc 91 and an oil pressure display Tube 92, the upper surface of the turntable 8 is in contact with the surface of the wedge-shaped disk 91, the turntable 8 can rotate, and the wedge-shaped disk 91 can move up and down relative to the turntable 8; the turntable 8 and the wedge-shaped disk 91 are arranged on In the lubricating oil tank 16 and immersed in the lubricating oil; there is a wedge-shaped gap between the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com