A Simulation Method of Abrasive Flow Machining for Quality Control

A simulation method and abrasive flow technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of insufficient uniform dispersion of experimental points, reduce the number of experiments, and fail to achieve neat comparability, etc., to achieve Fewer trials, better roughness, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

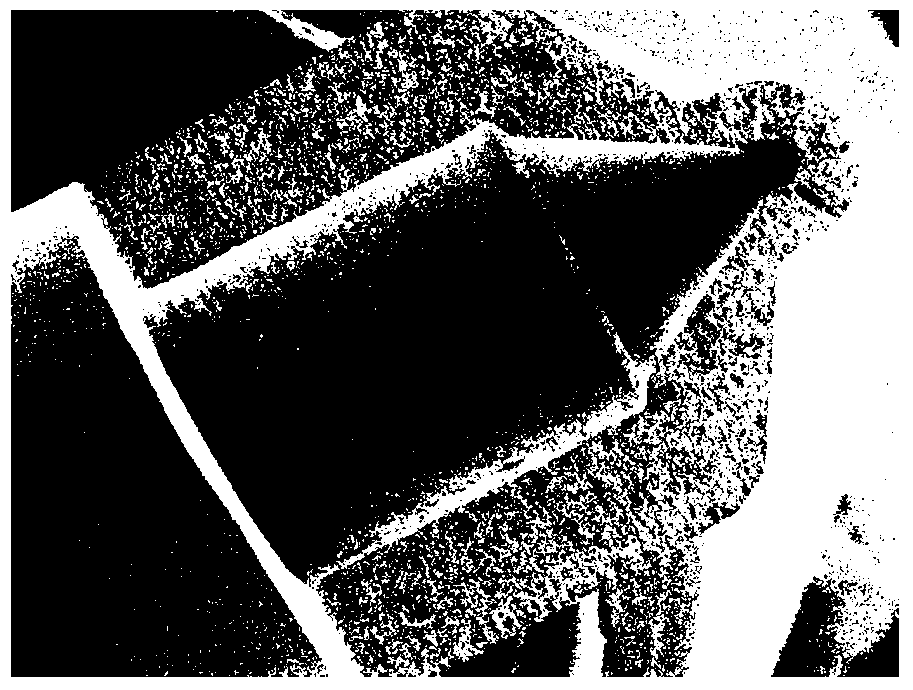

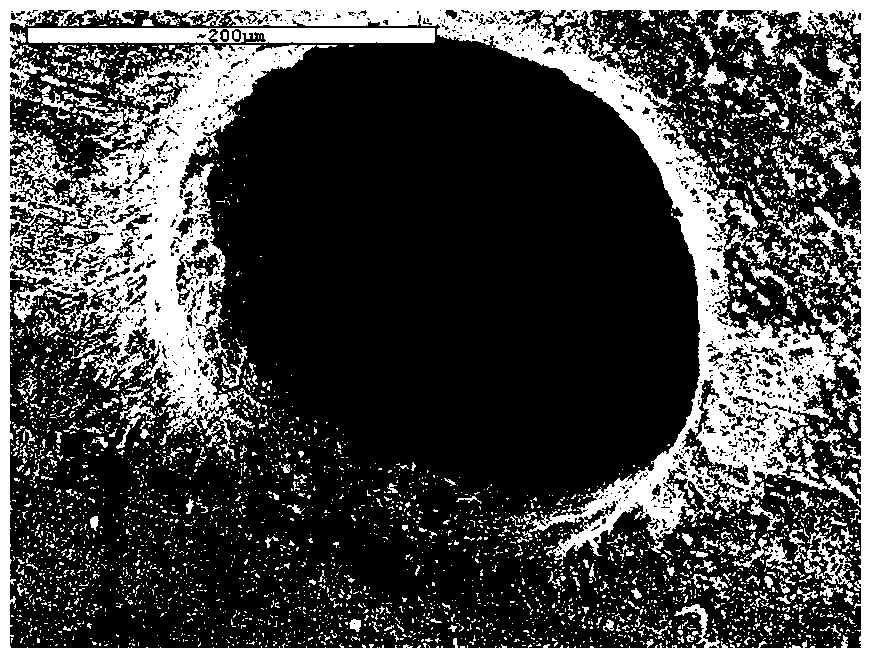

[0018] The simulation method of abrasive flow processing for quality control in this embodiment is based on the results of simulation, by introducing different pH values, combining different processing factors, and selecting processing parameters through the uniform design method to conduct abrasive flow processing experiments , first design the AFM factor table, the specific steps are as follows:

[0019](1) Select processing parameters. In the abrasive flow processing experiment, there are many factors that affect the grinding process, including the selection of abrasive particles (abrasive particle type, abrasive particle size, abrasive particle concentration, etc.), processing time, and inlet pressure. , the initial temperature of the hydraulic cylinder, etc., among many parameters, the processing time and abrasive concentration (ie key factors) that can significantly affect the processing effect, according to the theory of dissipative particle dynamics in the mesoscopic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com