A test and detection method for the size of structural defects

A detection method and a technology for structural defects, which are applied in the field of defect detection and can solve problems such as uneconomical use of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In project implementation, the specific implementation steps are as follows:

[0019] The first step is to obtain the input conditions of the structure of the inspected part, including the shape and size of the inspected part structure, the stress and force form of the inspected part structure during use, the fatigue loading history of the structure; the materials used for the inspected part structure The crack growth rate curve, the possible damage form and residual strength curve of the structure of the tested part;

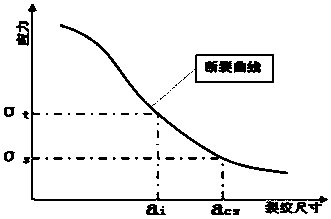

[0020] The second step is to calculate the maximum service stress σ of the tested component structure s Theoretical limit crack size under a cs , calculated according to the remaining strength curve to obtain the maximum service stress σ of the tested part s The theoretical limit crack size of the lower structure a cs ;

[0021] The third step is to set the theoretical limit crack size a under the overload stress of the structure of the inspected par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com