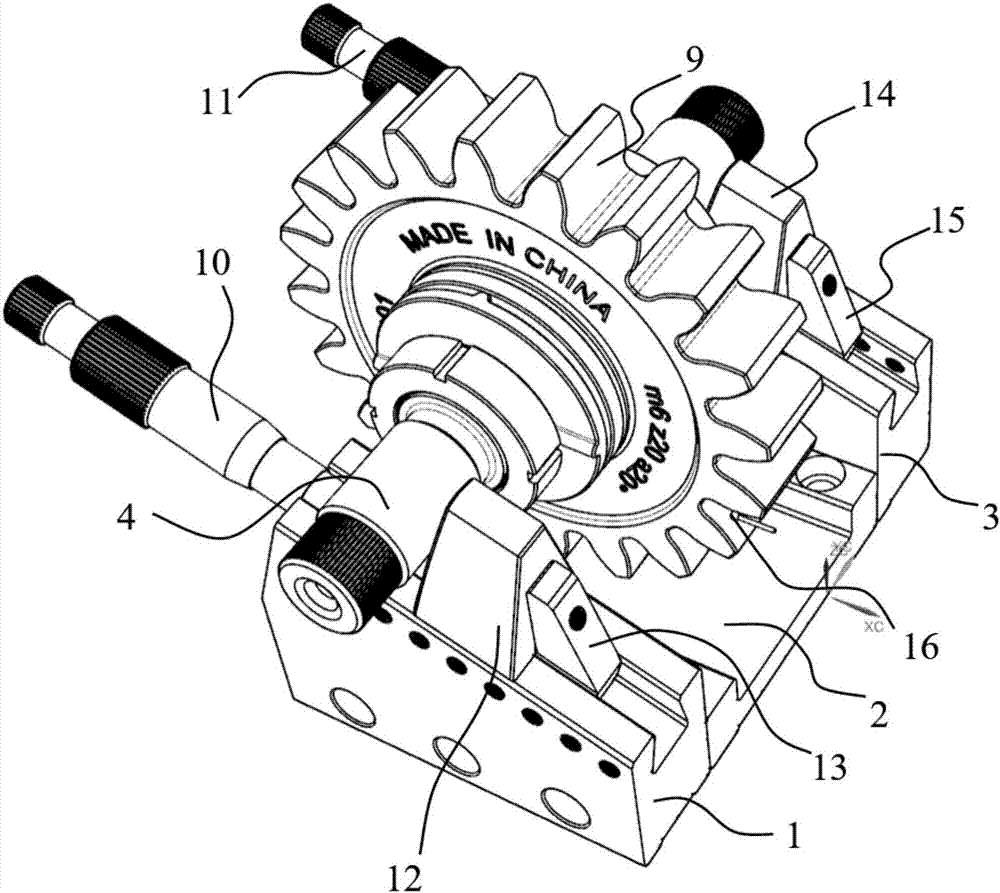

A high-precision positioning device for measuring the helix of straight-toothed standard gears

A positioning device and standard gear technology, applied in measuring devices, instruments, etc., can solve problems such as adjustment and precise positioning without high precision, achieve good promotion value and market application prospects, high structural rigidity, and reduce the burden of precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

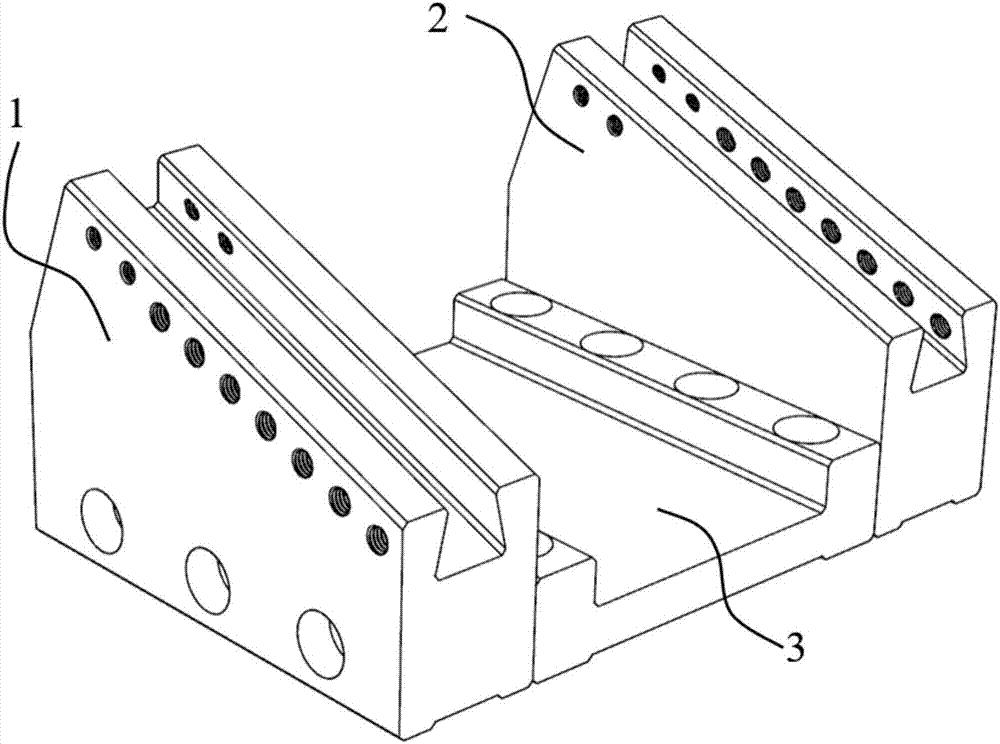

Embodiment Construction

[0022] There are two processing methods for fixed guide rail components: split processing and integral processing. The use of split processing is that since the two guide rails are symmetrical structures, in order to ensure their dimensional consistency, the two guide rails are processed as a whole before grinding, and then divided into two by wire cutting. Grind the connecting reference planes of the two guide rails and the connecting plate, and connect the guide rails and the connecting plate together with screws on the reference plate. During the connection process, as long as the bottom planes of the three are coplanar and the end surfaces of one side are coplanar, the working planes of the guide rails are basically coplanar. The assembled fixed guide rail components are uniformly aged to reduce the internal stress generated by the screw connection and improve the overall dimensional stability of the components. Integral processing is to process the guide rail and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com